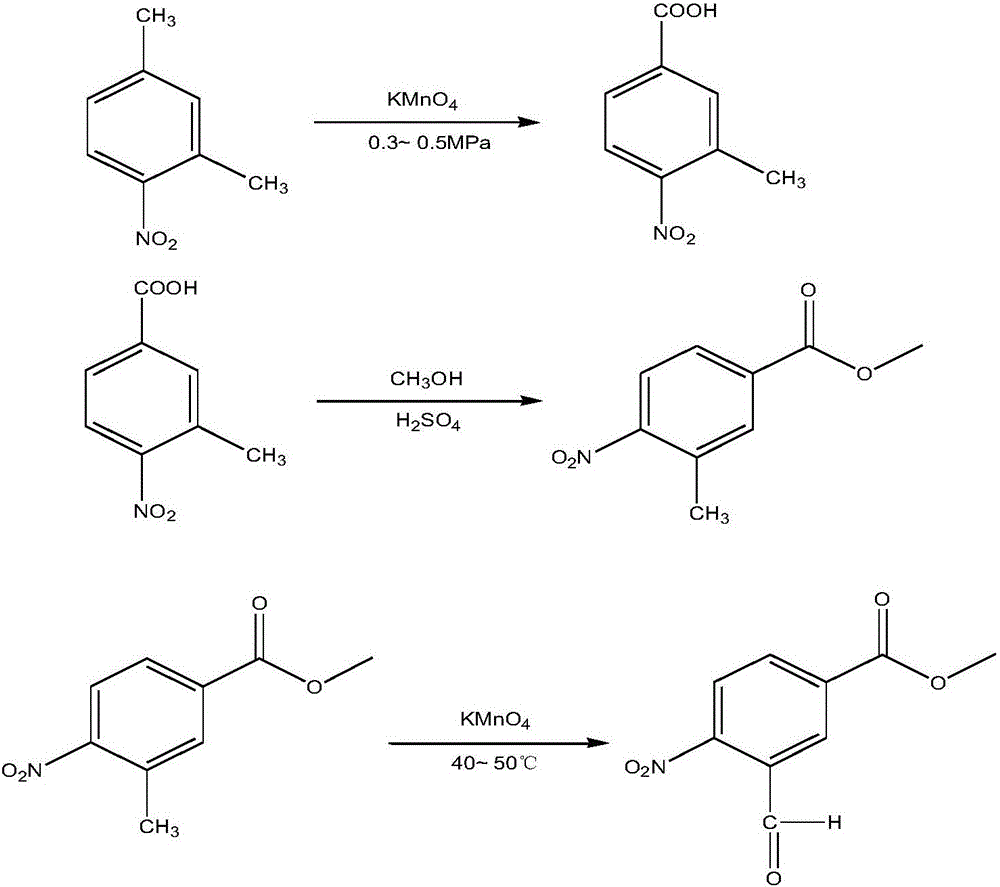

Synthesis method for 3-formyl-4-methyl nitrobenzoate

A technology for the synthesis of methyl nitrobenzoate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of no ideal industrial production method, backward process, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Add 35g of 2,4-dimethylnitrobenzene and 4g of tetrabutylammonium bromide into a 2L three-neck flask equipped with a stirrer, thermometer and dropping funnel, and add 1000mL of distilled water, transfer to a water bath, and heat up to 90 ℃, start the stirrer to stir at a speed of 300r / min; during the stirring process, add 85g potassium permanganate in 3 times, continue to stir for 1h, filter and separate immediately to obtain the filtrate, and adjust it with a sulfuric acid solution with a mass concentration of 30%. pH to 3, poured into a Buchner funnel, washed with deionized water and suction filtered 3 times to separate the solid powder; in a 2L three-necked flask equipped with a mechanical stirrer, put 70g of the above-mentioned separated solid powder and 700mL of mass concentration. Put 40% methanol solution in a water bath, heat to 90°C to dissolve for 20 minutes, then slowly add 50 mL of sulfuric acid solution with a concentration of 0.2 mol / L dropwise through a pip...

example 2

[0017] Add 40g of 2,4-dimethylnitrobenzene and 4g of tetrabutylammonium bromide into a 2L three-necked flask equipped with a stirrer, thermometer and dropping funnel, and add 1100mL of distilled water, transfer to a water bath, and heat up to 95 ℃, start the stirrer to stir at a speed of 350r / min; during the stirring process, add 90g of potassium permanganate in 4 times, continue to stir for 1h, filter and separate immediately to obtain the filtrate, and adjust it with a sulfuric acid solution with a mass concentration of 30%. pH to 3, poured into a Buchner funnel, washed with deionized water and suction filtered 4 times to separate the solid powder; in a 2L three-necked flask equipped with a mechanical stirrer, put 75g of the above-mentioned separated solid powder and 750mL of mass concentration. Put 40% methanol solution in a water bath, heat to 93°C to dissolve for 25 minutes, then slowly add 55 mL of sulfuric acid solution with a concentration of 0.2 mol / L dropwise through ...

example 3

[0019] Add 45g of 2,4-dimethylnitrobenzene and 5g of tetrabutylammonium bromide to a 2L three-neck flask equipped with a stirrer, thermometer and dropping funnel, and add 1200mL of distilled water, transfer to a water bath, and heat up to 100 ℃, start the stirrer to stir at a speed of 400r / min; during the stirring process, add 95g potassium permanganate in 5 times, continue to stir for 2h, filter and separate immediately to obtain the filtrate, and adjust it with a sulfuric acid solution with a mass concentration of 30%. pH to 4, poured into a Buchner funnel, washed with deionized water and suction filtered 5 times to separate the solid powder; in a 2L three-necked flask equipped with a mechanical stirrer, put 80g of the above-mentioned separated solid powder and 800mL of mass concentration. Put 40% methanol solution in a water bath, heat to 95°C to dissolve for 30 minutes, then slowly add 60 mL of sulfuric acid solution with a concentration of 0.2 mol / L dropwise through a pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com