Building formwork for highway bridges

A technology of building templates and wooden boards, which is applied in bridge construction, bridges, buildings, etc., can solve the problems of strength and rigidity, cheap use and high turnover times, and achieve the effects of light weight, quick installation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

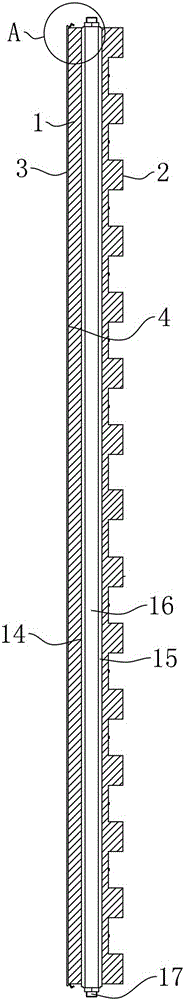

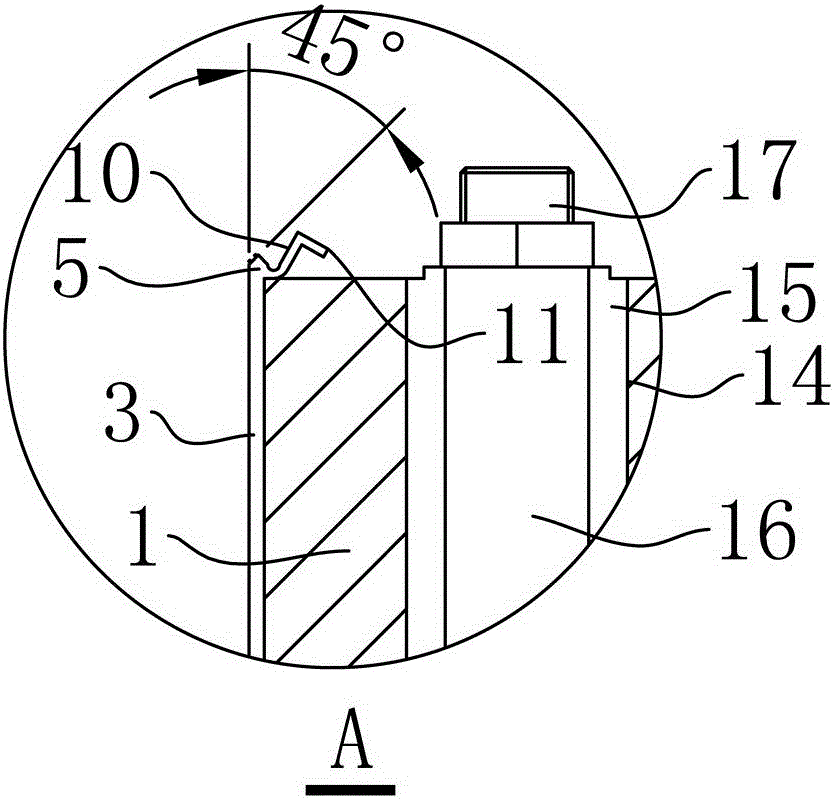

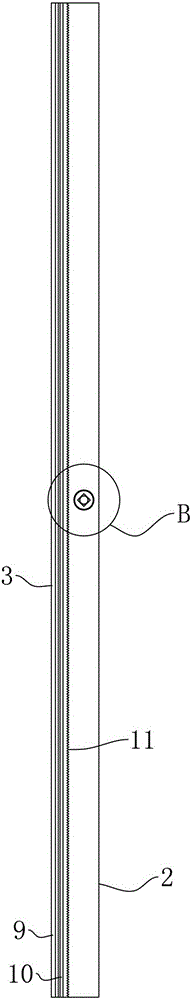

[0020] Embodiment one: Figure 1 to Figure 7 As shown, the building formwork for highway bridges includes a square wooden board 1. The wooden board 1 can be selected as density board or plywood, and of course a solid wood board can also be selected. One end face of the wooden board 1 is a plane structure, and the end face opposite to the plane structure There are convex ribs 2 arranged at intervals. When the wooden board 1 is a solid wood board, the convex ribs 2 can be integrally formed with the wooden board 1, and the wooden board 1 is a density board or a plywood, and the convex ribs 2 can be fixed by self-tapping or gluing , the convex ribs 2 are arranged in the same direction to form a rectangular array. The setting of the convex ribs 2 is mainly to play the role of the back edge when the formwork is used, so as to facilitate the extrusion and fixing of the formwork. The planar structure is provided with light metal Wrapping part 3, said wrapping part 3 is made of magnesi...

Embodiment 2

[0021] Embodiment 2: Of course, on the second docking interface 9 of the transition part 5, the positioning pin 12 and the positioning hole 13 can also be set in the same manner as the first docking interface 8, so as to facilitate the docking during installation. 1 structure, that is, the central hole 14 is respectively opened on the end face of the thickness of the wooden board 1, and two are symmetrically distributed, and the central hole 14 is respectively fixed and connected to the bushing, and the fixed rod 16 is arranged in the bushing, that is, the two are fixed. Respectively exposed outside the central hole 14 , the exposed part of the fixing rod 16 is provided with a fixing part 17 , and the fixing part 17 includes a positioning section in a square structure and a threaded section extending outward from the positioning section.

[0022] When the present invention is actually used, this formwork is suitable for pouring concrete with a large square cross-section. When m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com