Building Construction Formwork Climbing System

A technology for building construction and formwork, applied in the field of building construction formwork climbing system, can solve the problems of easily winding scaffolding, cumbersome cable layout, complex structure, etc., and achieve the effects of cost reduction, light weight and rapid formwork climbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

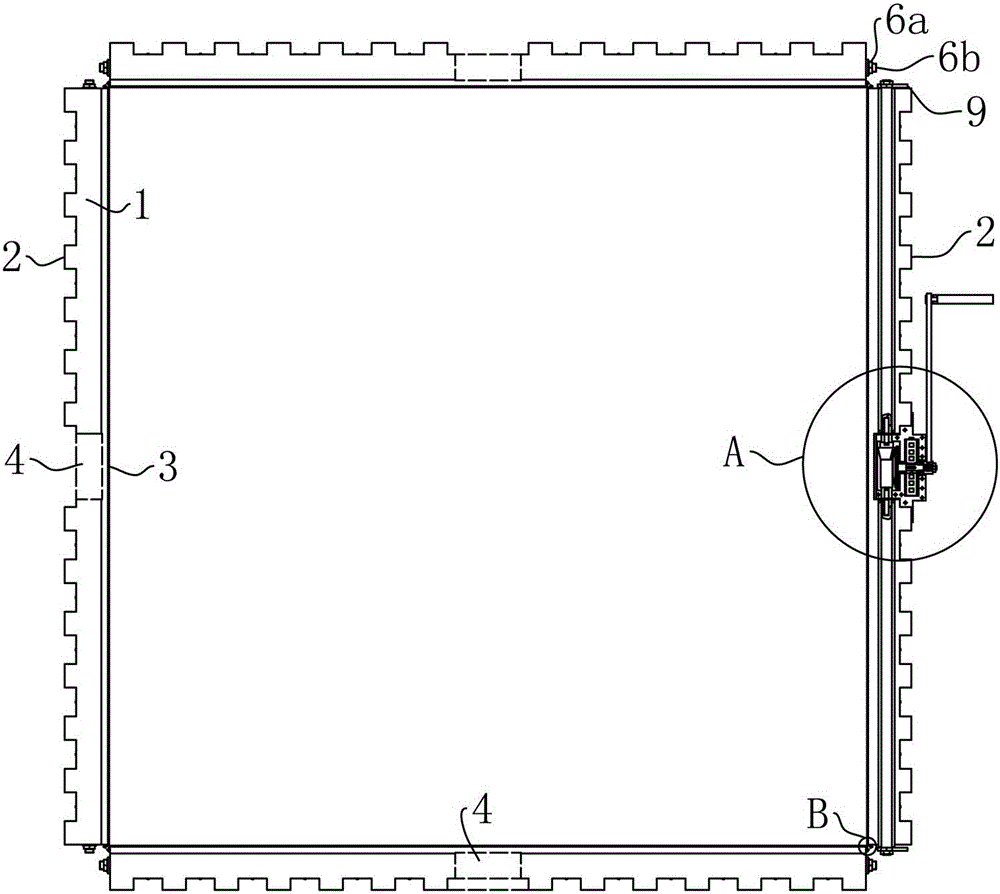

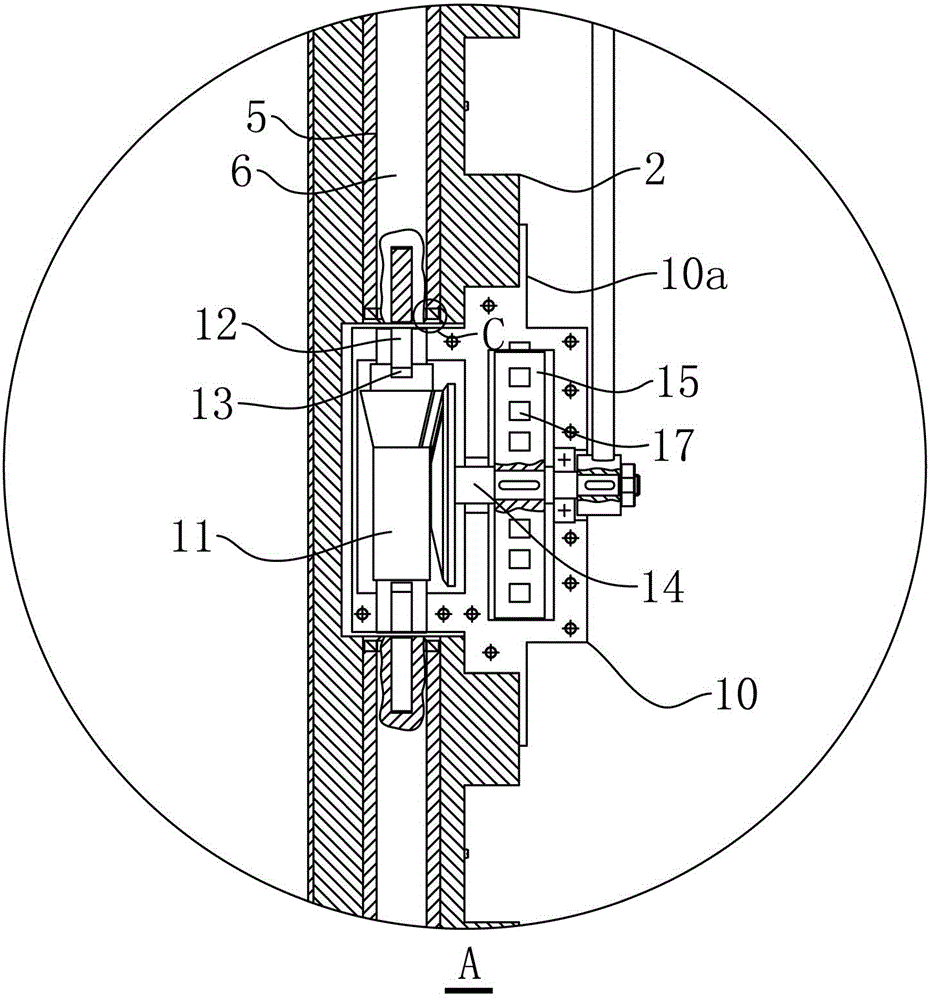

[0031] Embodiment one: Figure 1 to Figure 13 As shown, the building construction formwork climbing system includes formwork and power system;

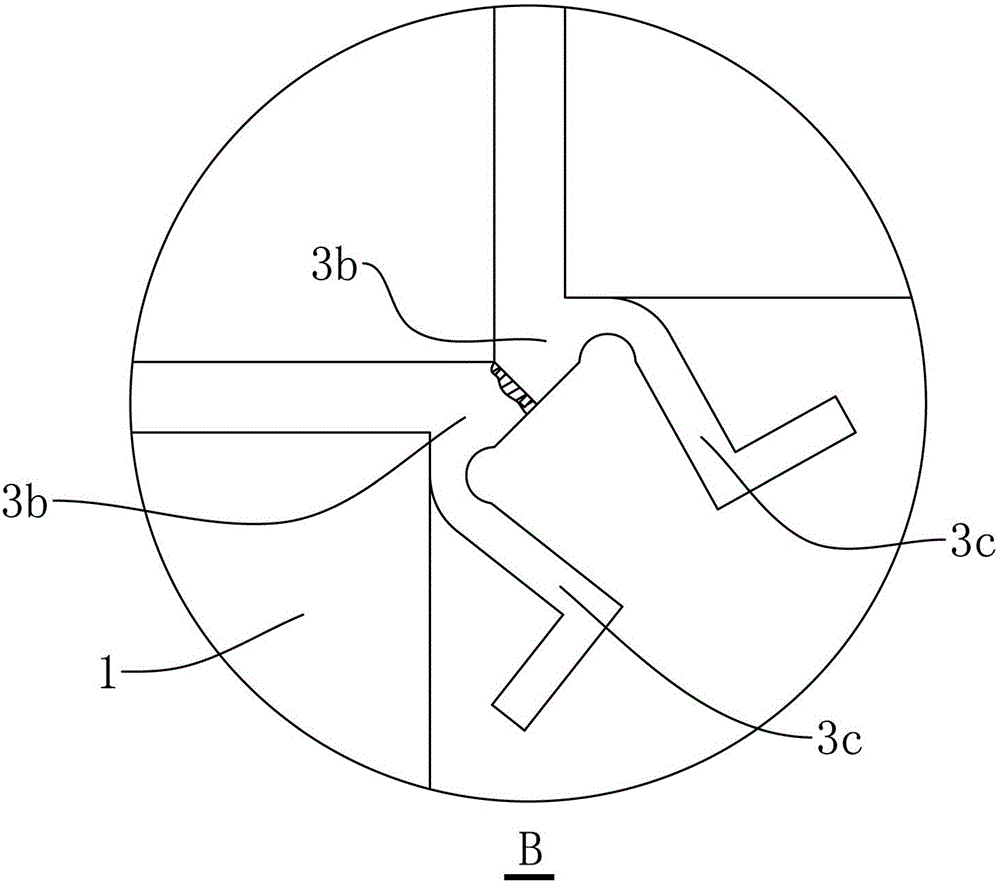

[0032]Described formwork comprises a square wooden board 1, and described wooden board 1 is density board or solid wood board or plywood, and one end face of wooden board 1 is plane structure, and the end face opposite to plane structure is provided with the protruding rib 2 that is arranged at intervals , each convex rib 2 is arranged in a rectangular array in the same direction, and the planar structure is provided with a wrapping part 3 made of light metal, and the wrapping part 3 is made of magnesium-aluminum alloy, and the wrapping part 3 cooperates with the wooden board 1 The thickness of the bottom of the groove 3a is 2 to 4mm, and the wrapping part 3 is provided with a groove 3a corresponding to the planar structure of the wooden board 1, so that the wooden board 1 is placed in the groove 3a and connected to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com