Electrical conduit beam penetrating bottom formwork embedded part without hole

A technology of electrical conduits and embedded parts, which is applied in the field of electrical conduits passing through the beam bottom formwork without opening holes, which can solve the problems of waste of construction time, quality defects, a large amount of sawdust, wood chips, etc., to save construction time and avoid crossing The effect of operations and guaranteed turnover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The hole-free embedded part of the electric conduit passing through the beam bottom formwork of the present invention includes the embedded part body.

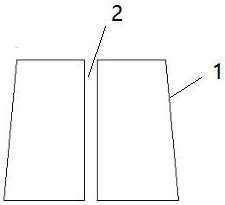

[0028] see now figure 1 , figure 1 It is a schematic diagram of the embedded part structure of the embodiment of the present invention. As shown in the figure, the embedded part 1 is a circular platform, and a small hollow cylinder 2 is arranged in the middle of the circular platform for passing the fixing nail 3. The diameter of the small cylinder is equal to the diameter of the fixing nail. The material of the round table is rubber. The diameter of the bottom surface of the circular platform needs to match the diameter of the electrical conduit.

Embodiment 2

[0030] The construction steps of the electrical conduit piercing the beam bottom formwork of the present invention are free from openings and embedded parts:

[0031] 1. After the installation of the beam slab formwork is completed, the operator draws the positioning line of the beam pipe on the beam bottom formwork according to the hydropower professional drawings, and uses fixing nails to position and install the embedded parts.

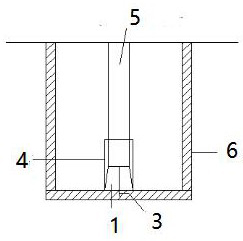

[0032] 2. After checking the accurate positioning of the embedded parts, install the casing on the embedded parts. The ports of the casing should be smooth and tidy. After the installation is completed, the lower end of the PVC casing 4 should be close to the beam formwork 6.

[0033] 3. After the casing is installed firmly, insert the PVC threading pipe 5 into the casing for fixing.

[0034] 4. Pouring concrete. Install another section of PVC threading pipe at the bottom of the beam after the formwork is removed.

[0035] The present invention h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com