Heat absorber of a linear Fresnel heat collection system

A linear Fresnel, heat sink technology, applied in solar collectors, solar heating systems, solar collectors using working fluids, etc., can solve the problems of difficult installation and maintenance, complex structure, etc. Simple and reliable, simple overall structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are for explanation rather than limitation of the present invention.

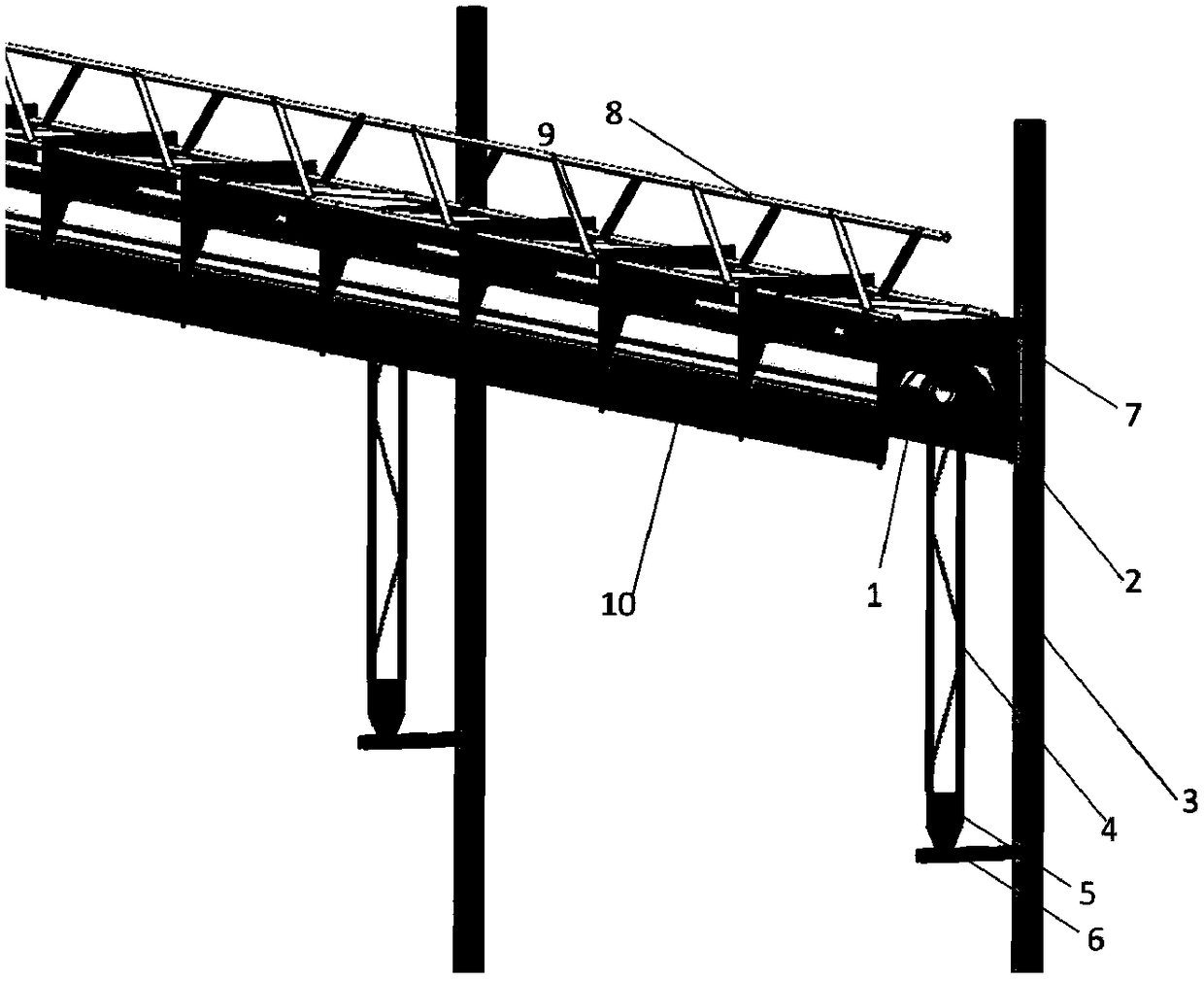

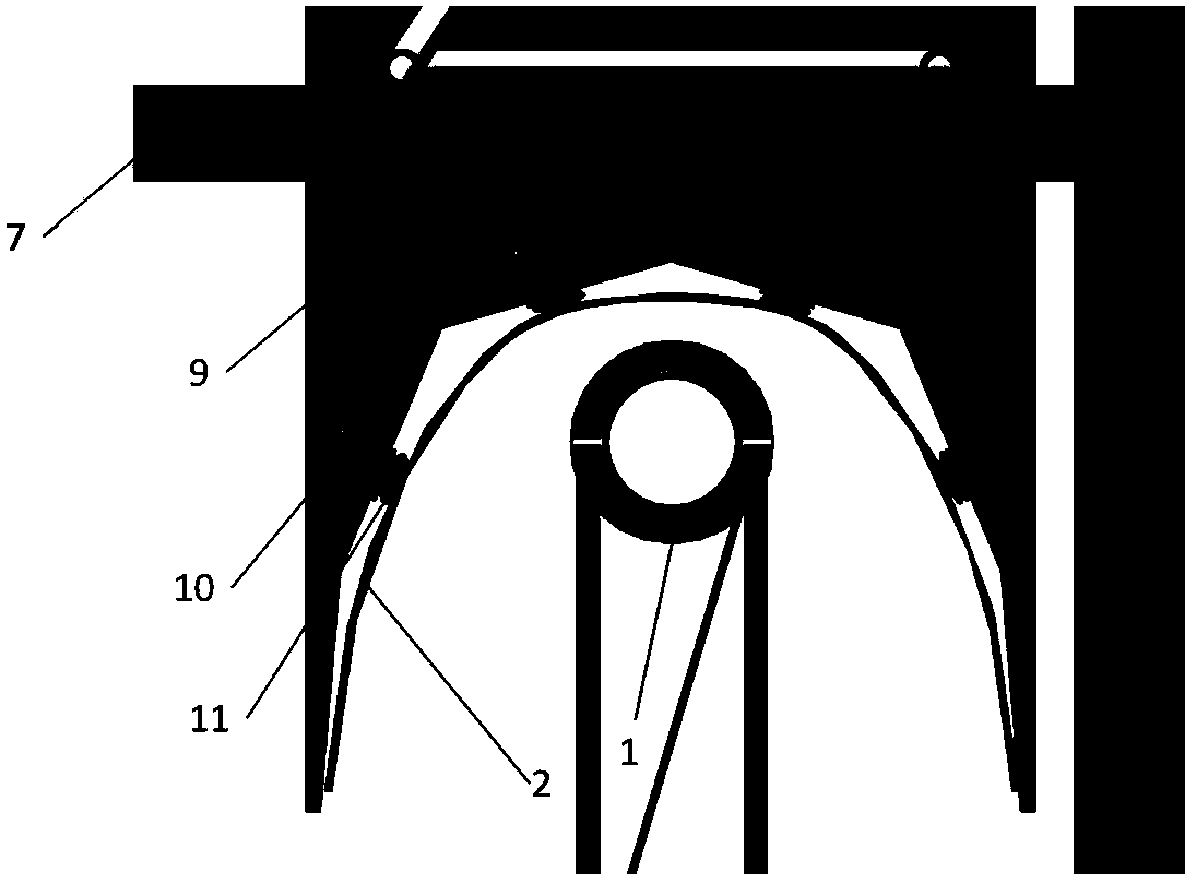

[0024] See figure 1 , figure 2 , A heat absorber of a linear Fresnel heat collection system, comprising a heat collection tube 1, a secondary reflector 2 and a column 3 supporting the heat absorber. The heat collection tube 1 is fixed to the column 3 through a support rod 4 On the connected lower beam 6, a spring steel sheet 5 is also provided between the support rod 4 and the lower beam 6; the secondary reflector 2 is connected to a plurality of vertical plates 9 respectively, and the vertical plates 9 are fixed to the column 3 The upper upper beam 7 is connected or connected with the frame 8 fixed between the uprights 3.

[0025] Specifically, both sides of the frame 8 are provided with uprights 3 and respectively connected to them. The uprights 3 are arranged in pairs and are arranged at eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com