Wheel-leg-arm-tank combined explosive disposal robot

An explosive-removing robot and wheel-leg technology, applied in the field of robotics, can solve the problems of insufficient transportation safety of explosives, limited passing ability, explosives explosion, etc., so as to improve the ability to deal with diverse tasks, improve safety, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

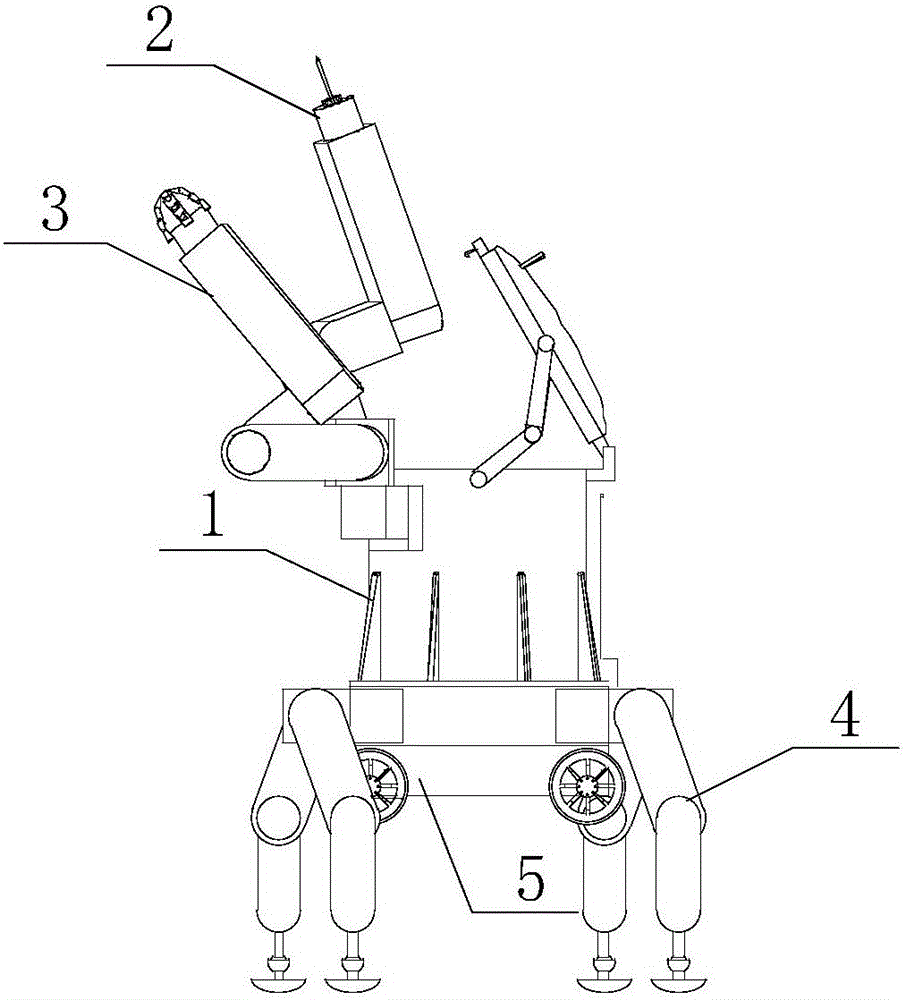

[0021] Referring to the accompanying drawings, an explosion-proof robot combined with wheels, legs, arms and tanks includes: an explosion-proof tank 1, a dismantling robot arm 2, a grabbing robot arm 3, a robot leg 4, and a frame 5 with rollers;

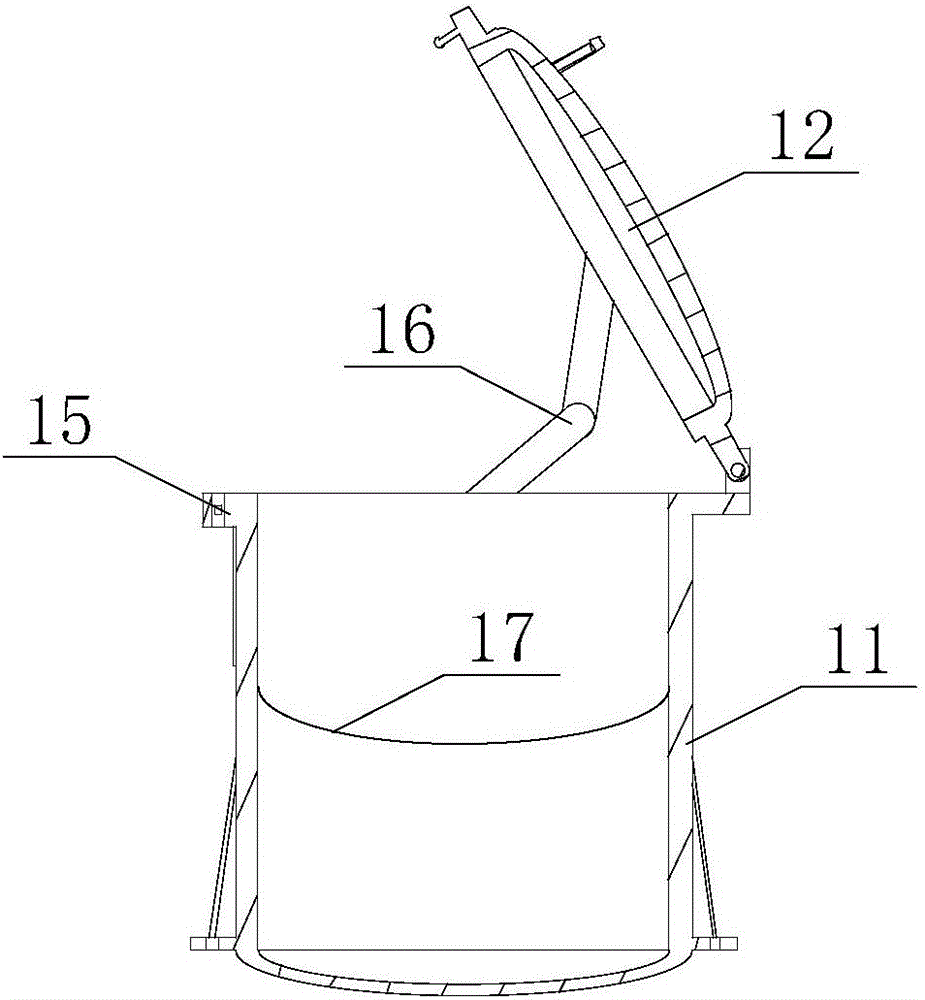

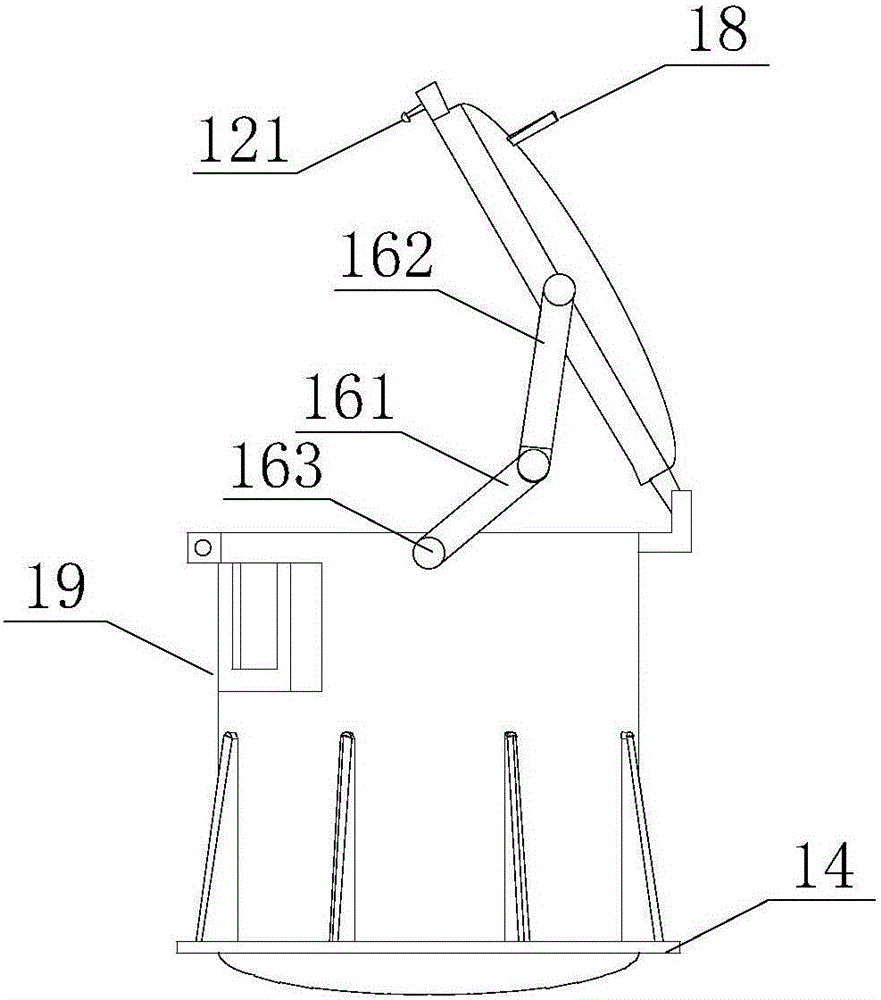

[0022] The explosion-proof tank 1 is installed on the vehicle frame 5, including: a tank body 11, a tank cover 12 movably connected with the tank body 11, a connecting rod 16 installed in the tank body 11 and providing support when the tank cover is opened, installed on the tank body 11 The flange 14 at the bottom, the buffer net 17 installed in the tank body 11, the two slots 19 installed on the side wall of the tank body 11 and the locking mechanism 15 for locking the tank cover 12;

[0023] The dismantling mechanical arm 2 is installed in a draw-in slot 19 of the explosion-proof tank 1, including: shoulder joint 21, big arm 22, middle arm 24, forearm 26, wrist joint 27, dismantling manipulator 28; Joint, swing arm joint, has two d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com