Optical surface profile scanning system

A surface profile and scanning system technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of probe wear or damage, increased use cost, probe scratches, etc., and achieve short measurement time and good image quality , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

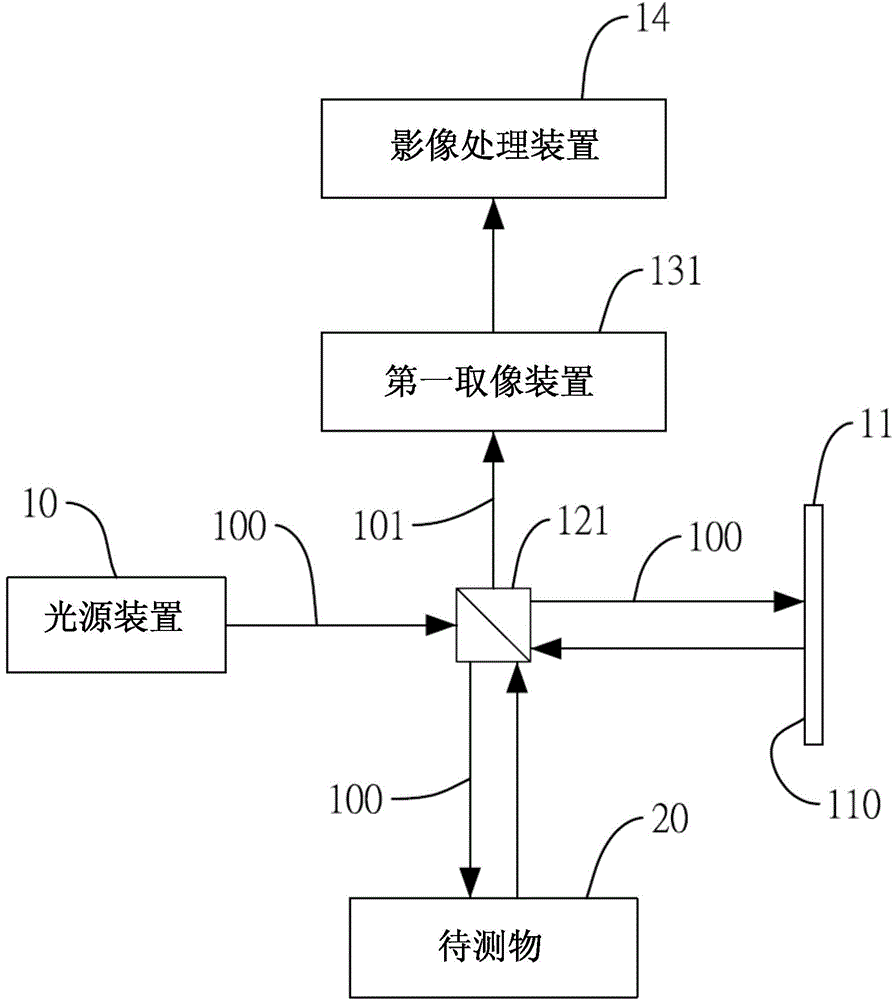

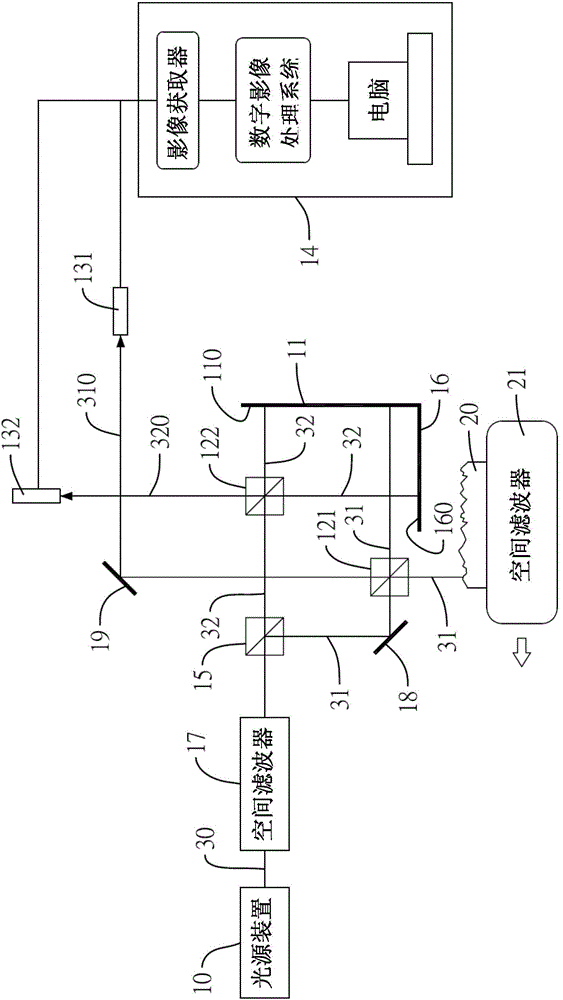

[0039] Please refer to figure 1 , The optical surface profile scanning system of the present invention mainly includes a light source device 10 , an interference mirror 11 , a first beam splitter 121 , a first imaging device 131 and an image processing device 14 .

[0040] The light source device 10 can be a He-Ne laser device or a LED device for emitting a detection beam 100 . The interference reflector 11 has an interference reflective surface 110, and the interference reflective surface 110 can face the light source device 10 for reflecting light beams.

[0041] The first spectroscope 121 is arranged in the optical path of the detection beam 100, and the detection beam 100 is simultaneously projected onto the surface of an object to be tested 20 and the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com