Steering bearing shaft washer channel parameter measuring instrument and measuring method

A steering bearing and parameter measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to give quantitative results, low measurement efficiency of the profiler, etc., to achieve digital measurement, reliable measurement results, and realization of measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

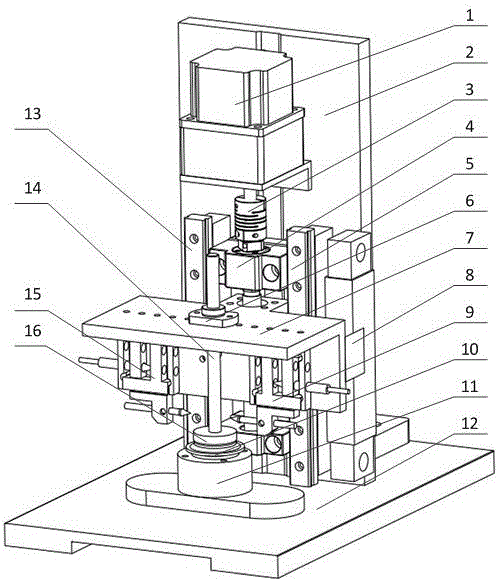

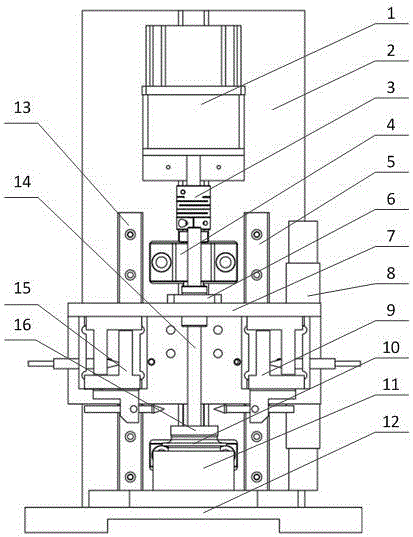

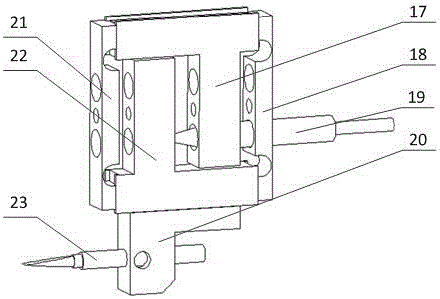

[0025] Such as Figure 1 to Figure 4 As shown, the system support 2 and the measurement platform 11 are fixed on the system plate 12, and the stepping motor 1, the ball screw support 4, the first linear guide 5, the second linear guide 13 and the grating ruler 8 are fixed on the system support 2 , the sensor frame 7 is fixed on the first linear guide rail 6 and the second linear guide rail 13, and is connected with the slider of the ball screw and the grating scale 8 at the same time, and the motor 1 is connected with the ball screw through the coupling 3 and drives it to rotate , the first sensor system 9 and the second sensor system 15, the linear bearing 6 are fixed on the sensor frame 7, the guide rod 14 is connected with the positioning pressure head 16, and can move up and down flexibly through the linear bearing 6, the positioning pressure head 16 and the linear A compression spring (not shown in the figure) is arranged between the bearings 6 to provide a compression fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com