Online oxidative wear state monitoring method based on color extraction of wear particle image

A technology for oxidizing wear and abrasive particles, which is applied in the directions of measuring devices, optical testing of flaws/defects, and material analysis through optical means. It can solve problems such as technical application limitations and inability to analyze in real time, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The method will be described below in conjunction with the accompanying drawings.

[0035] An online oxidation wear state monitoring method based on the color extraction of abrasive grain images, comprising the following steps:

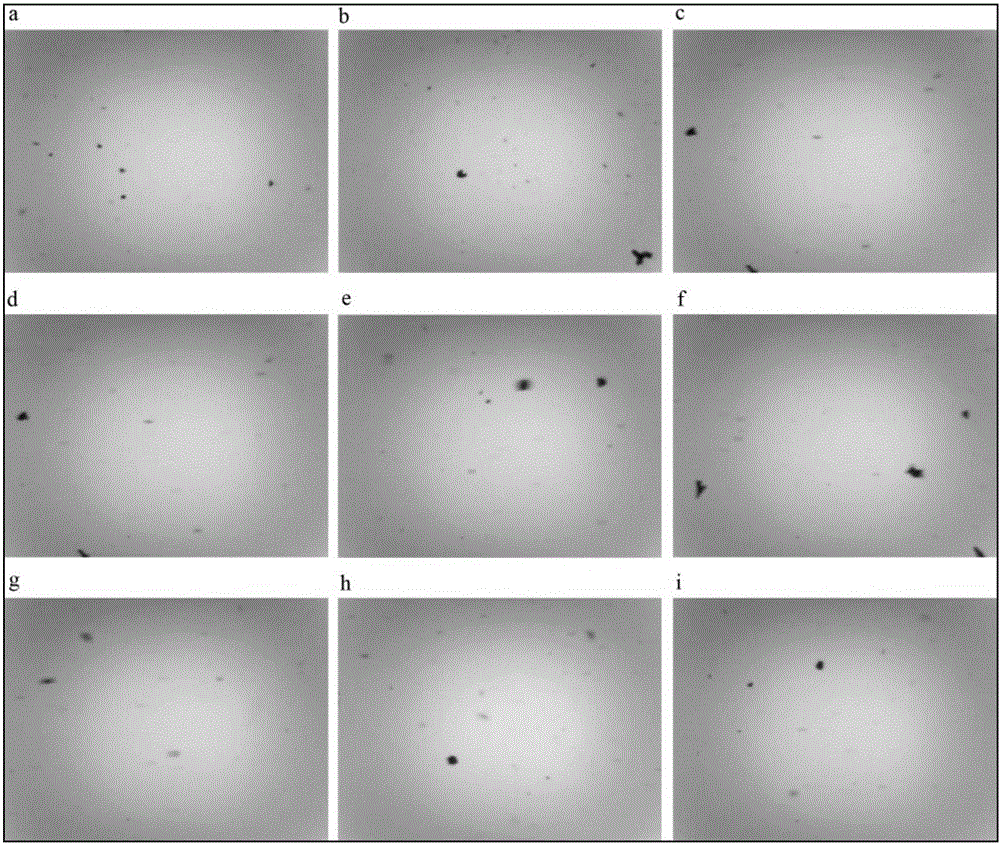

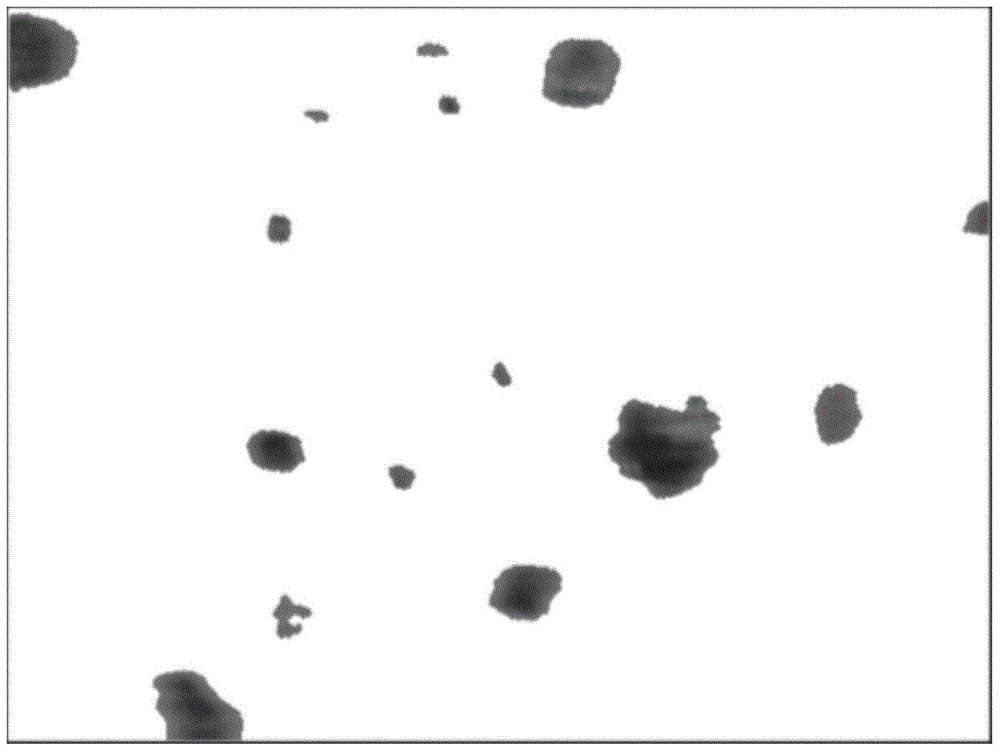

[0036] Step 1. Use a video-based on-line monitoring probe for lubricating oil abrasive particles (public number: CN201310141314.9) to obtain online images and videos of abrasive particles. Since online oxidation and wear state monitoring is used in industrial sites, it is a kind of Real-time monitoring means, so due to the influence of oil characteristics and environmental factors, the edge color and outline of abrasive grains in the collected images will become blurred, so it is necessary to perform background subtraction, filtering and blur restoration on the image in order to Obtain a clear image of wear particles. Such as figure 1 Nine images from a video stream are shown, each abrasive grain image consists of two parts, the abrasive grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com