Lamination optimum design method of wind turbine blade main beam

A wind turbine blade and optimization design technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of increasing its own weight, dragging down the operating efficiency of the wind turbine, increasing the cost of blades, etc., and achieving the effect of reducing the weight of the blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

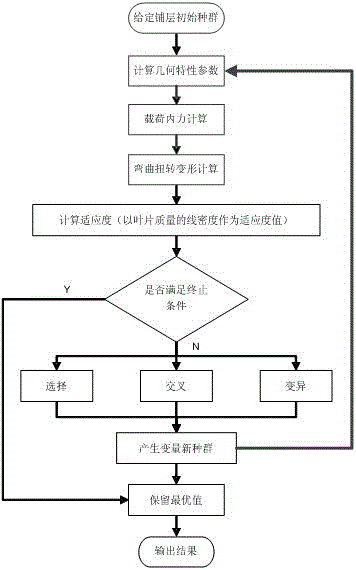

[0039] The present invention adopts following technical scheme:

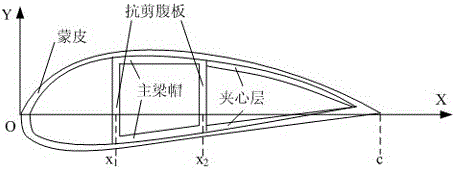

[0040] The first step is to select the appropriate aerodynamic shape parameters, divide the blades equidistantly into n segments to obtain your cross-section, and calculate the area of each section given the initial main beam lay-up thickness parameters;

[0041] The second step is to calculate the section area moment S x ,S y , centroid X c ,Y c , and moment of inertia I x , I y , I xy ;

[0042] The third step is to calculate the bending moment and torque of the aerodynamic force, gravity and centrifugal force on the blade;

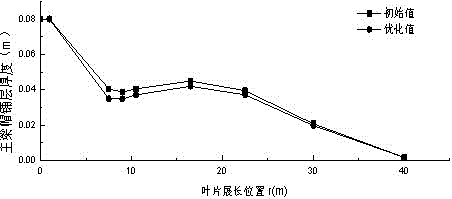

[0043] The fourth step is to calculate the linear density of the blade mass as the fitness value and the stiffness of a given layer thickness, and compare it with the maximum stress to eliminate the layer thickness that does not meet the requirements.

[0044] The fifth step is to obtain the optimization result by iterating a certain number of steps and select the optimal value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com