A kind of coil preparation method

A coil and bare wire technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as unusable, easy to drop paint, and reduce product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

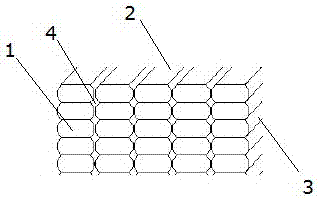

[0018] Specifically, in the embodiment of the present invention, such as figure 1 As shown, the coil preparation method includes the following steps:

[0019] (1) Prefabricated enameled wire: the metal conductor is drawn to form a circular bare metal wire, and the surface of the bare wire is covered with insulating varnish several times, and baked to form a circular enameled wire;

[0020] (2) Pressing: The round enameled wire in step (1) is pressed once by a pressure roller to form a winding enameled wire with smooth upper and lower surfaces and curved left and right sides;

[0021] (3) Winding: Fix one end of the winding enameled wire prepared in step (2), and stack it along the bottom of the iron core to the end to form the innermost layer 3; after winding, the innermost layer 3 is wound from the iron core in sequence The end of the winding enameled wire is stacked to the bottom to form the middle layer 2, and the outermost layer 1 is formed after repeated winding; the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com