Gelled electrolyte of gelled lead acid battery and preparation method thereof

A colloidal electrolyte and lead-acid battery technology, applied in the direction of lead-acid batteries, can solve problems such as potential safety hazards, three-dimensional structure changes, and affecting the effective function of microporous cracks "channels", so as to prolong the storage period, alleviate the hydration phenomenon, Improve practicality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

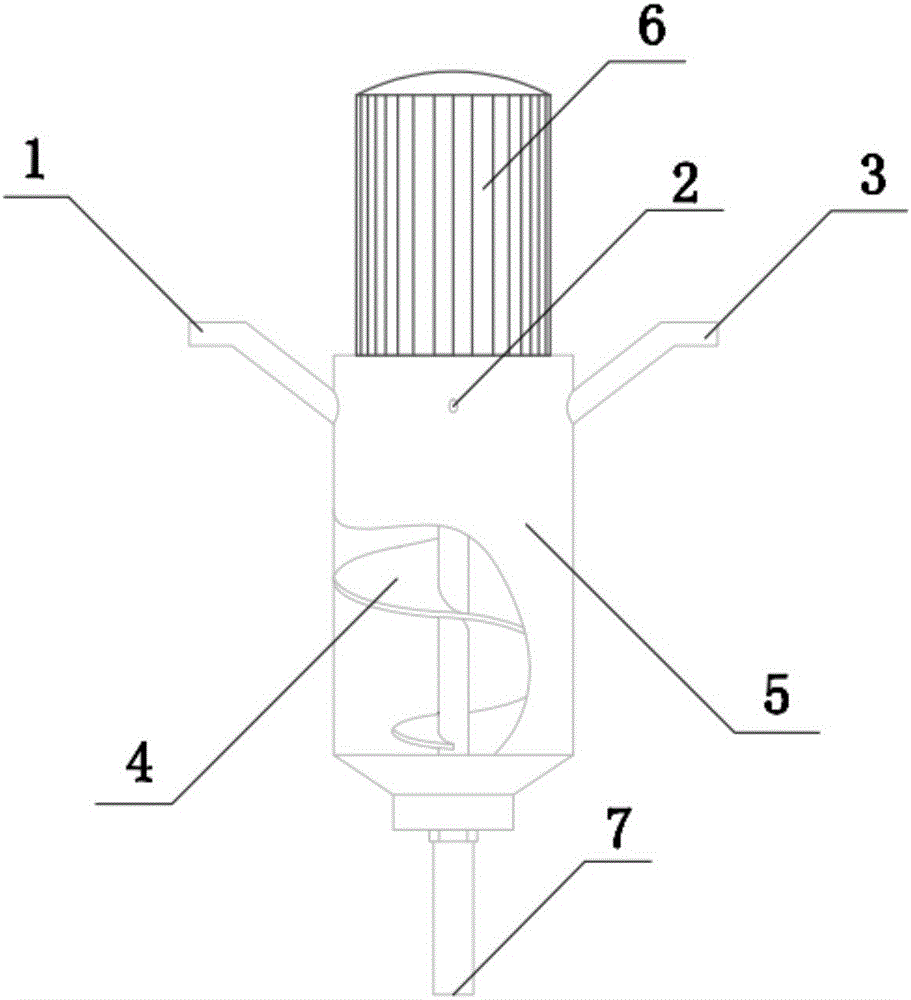

Image

Examples

Embodiment 1

[0029] A colloidal electrolyte for a colloidal lead-acid battery, the preparation method of which comprises the following steps:

[0030] 1) Preparation of acid gel: fumed silica (150g / m 2 ) and sulfuric acid (1.36g / cm 3 ) according to the mass ratio of 3.8:100 by mixing and stirring. The specific preparation steps are as follows: in a high-speed shear mixer, disperse the fumed silica in sulfuric acid for 3 times, respectively according to 50%, 35%, 15% The amount (accounting for the percentage of the total amount of fumed silica added in the acid gel) is added; with the increase of the amount of silica, the agitator will change the speed of fumed silica and sulfuric acid from low to high at a speed of 500-8000r / min. Stir and disperse, the whole dispersion time is 60min, and the acid gel with network colloidal structure is obtained;

[0031] 2) Preparation of water gel: fumed silica (150g / m 2 ) and pure water by mixing and stirring at a mass ratio of 18:100. The specific st...

Embodiment 2

[0035]A colloidal electrolyte for a colloidal lead-acid battery, the preparation method of which comprises the following steps:

[0036] 1) Preparation of acid gel: fumed silica (200g / m 2 ) and sulfuric acid (1.32g / cm 3 ) according to the mass ratio of 1.5:100 by mixing and stirring. The specific preparation steps are as follows: in a high-speed shear mixer, disperse the fumed silica in sulfuric acid for 3 times, respectively according to 50%, 35%, 15% The amount (accounting for the percentage of the total amount of fumed silica added in the acid gel) is added; with the increase of the amount of silica, the agitator will change the speed of fumed silica and sulfuric acid from low to high at a speed of 500-8000r / min. Stir and disperse, the whole dispersion time is 50min, and the acid gel with network colloid structure is obtained;

[0037] 2) Preparation of water gel: fumed silica (200g / m 2 ) and pure water by mixing and stirring at a mass ratio of 12:100, the specific steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com