Power-off synchronous operation method and system for frequency converter

A technology of synchronous operation and frequency converter, applied in the control system, electrical components, AC motor control, etc., can solve the problems of machine undervoltage or overvoltage, poor applicability, complicated debugging, etc., and achieve the effect of ensuring synchronization and easy debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

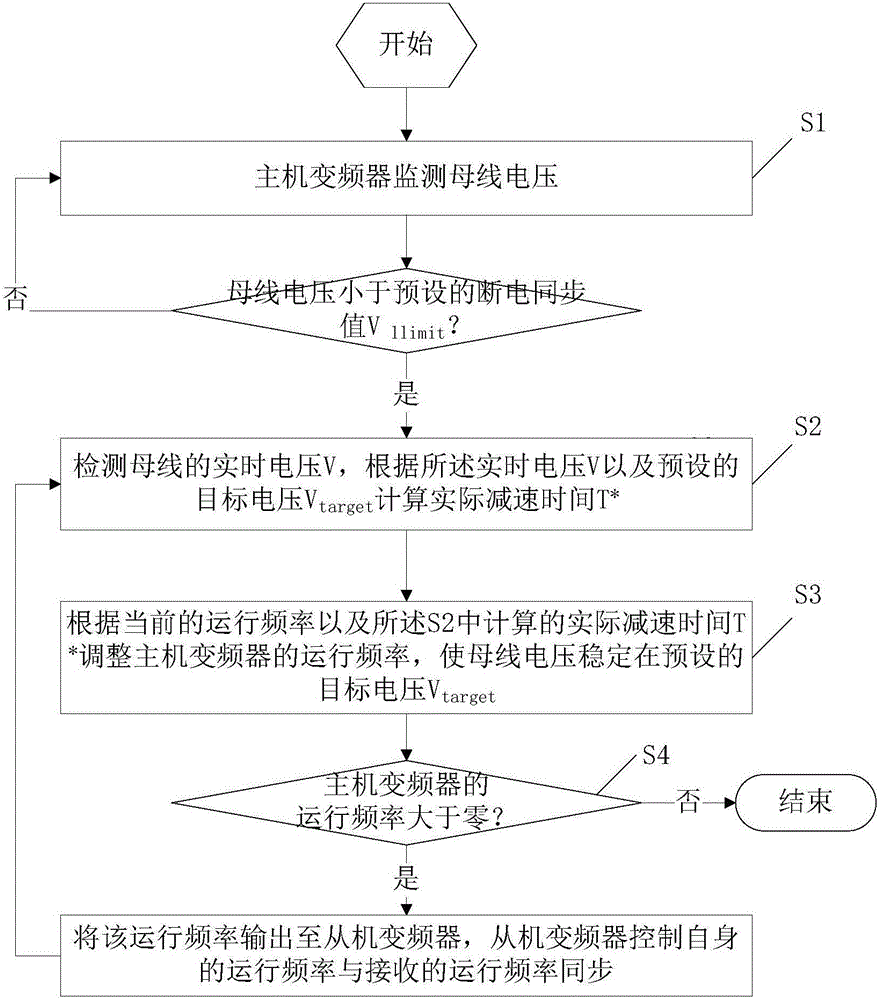

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

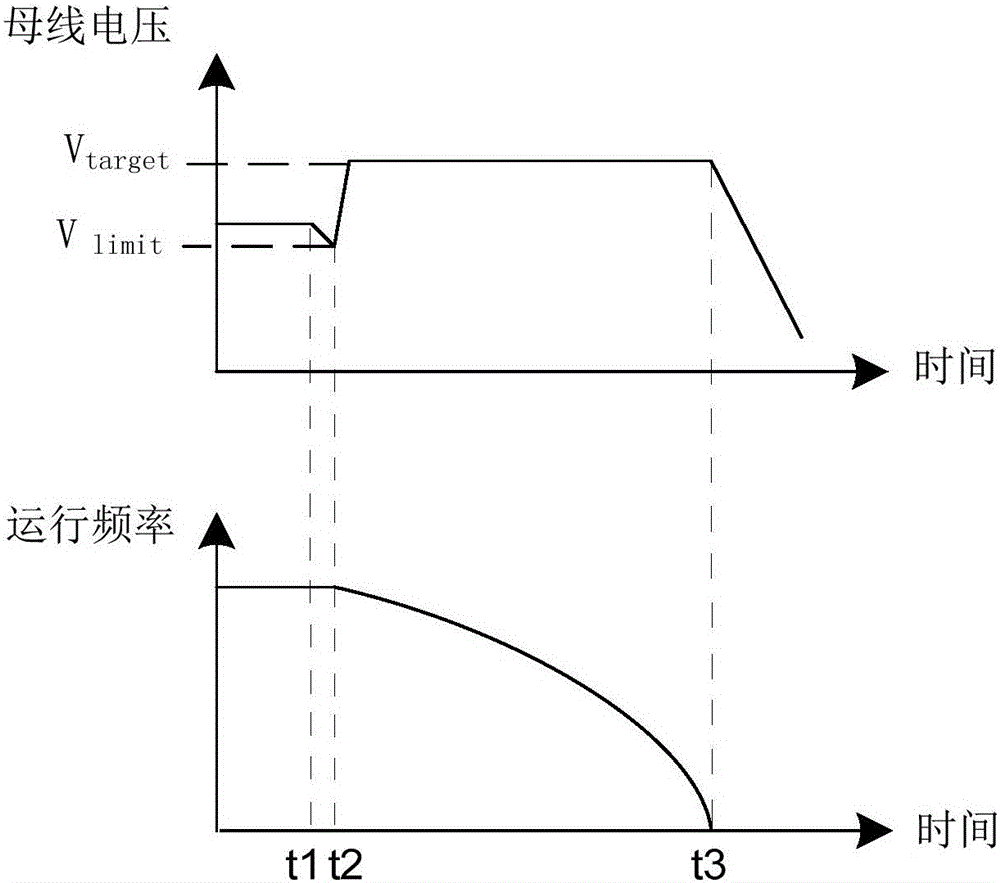

[0049] refer to figure 1 , is a schematic diagram of the bus voltage and the motor operating frequency changing with time based on the power-off synchronous operation method of the frequency converter of the present invention after the bus is powered off;

[0050] As shown in the figure, in the initial stage, the voltage supply is normal, and the bus voltage has been at a stable voltage. At a certain moment t1 suddenly loses power, the bus voltage drops. In order to maintain the bus voltage at a target level, the present invention is based on the principle that the motor can generate electricity when it decelerates quickly, and changes the deceleration speed of the motor in real time through the power-off synchronizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com