Cutting device

A technology for cutting devices and components, which is applied in the direction of shearing devices, operating devices, and attachments of shearing machines, etc. It can solve problems such as difficult fixing of knives or replacement of pressing components, time-consuming cleaning operations, and influence on bar cutting accuracy. Achieve the effect of eliminating bounce and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

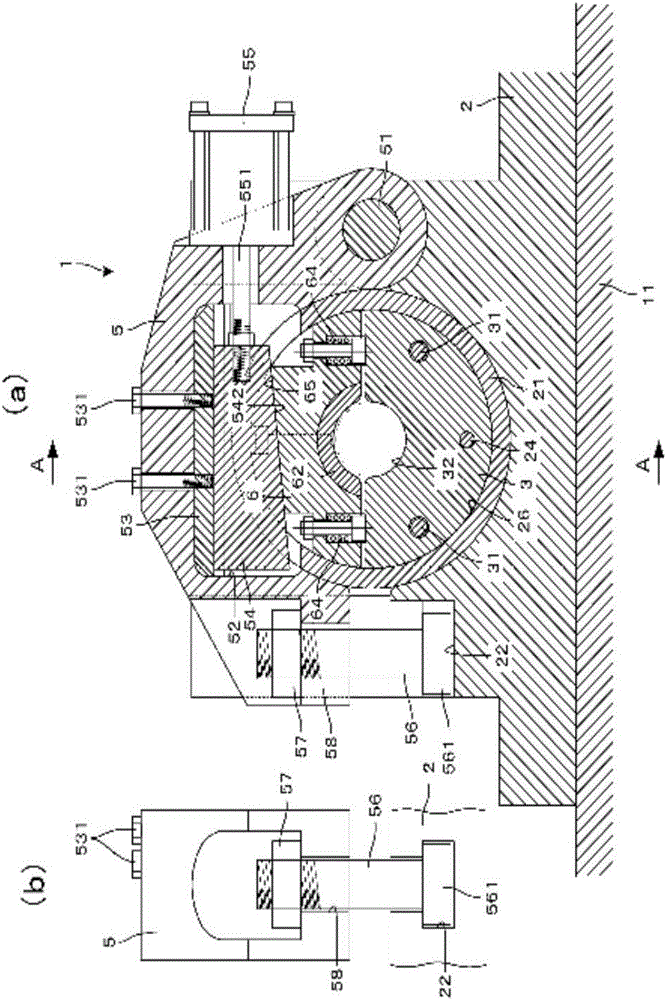

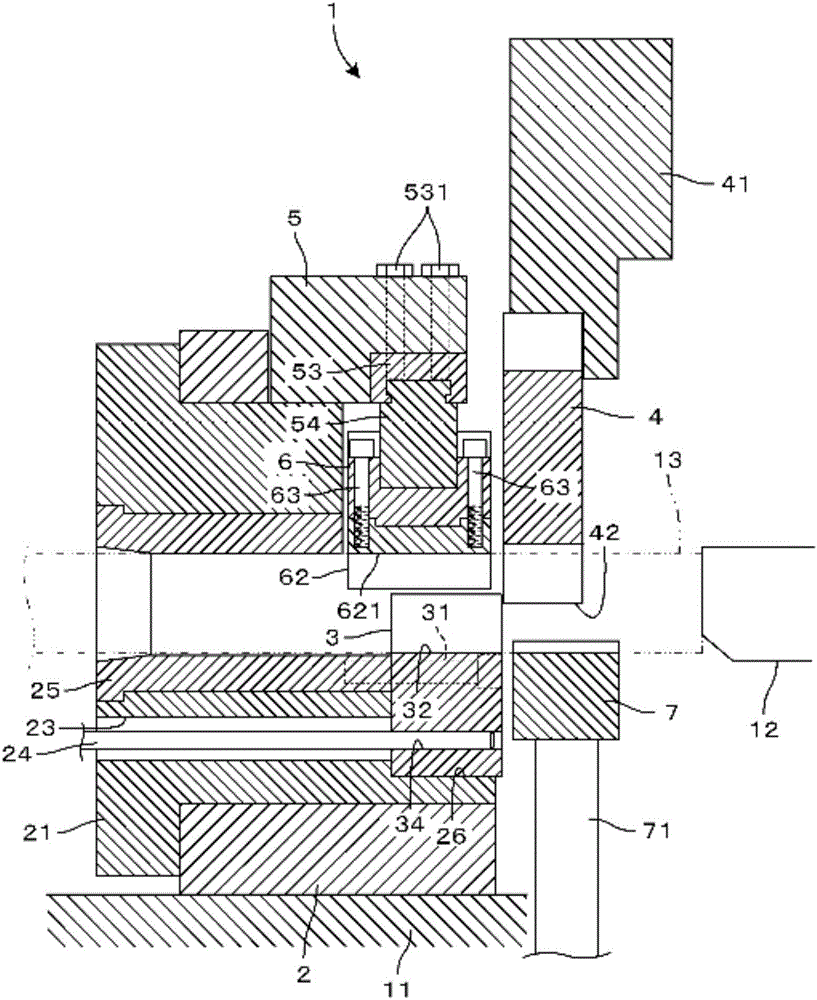

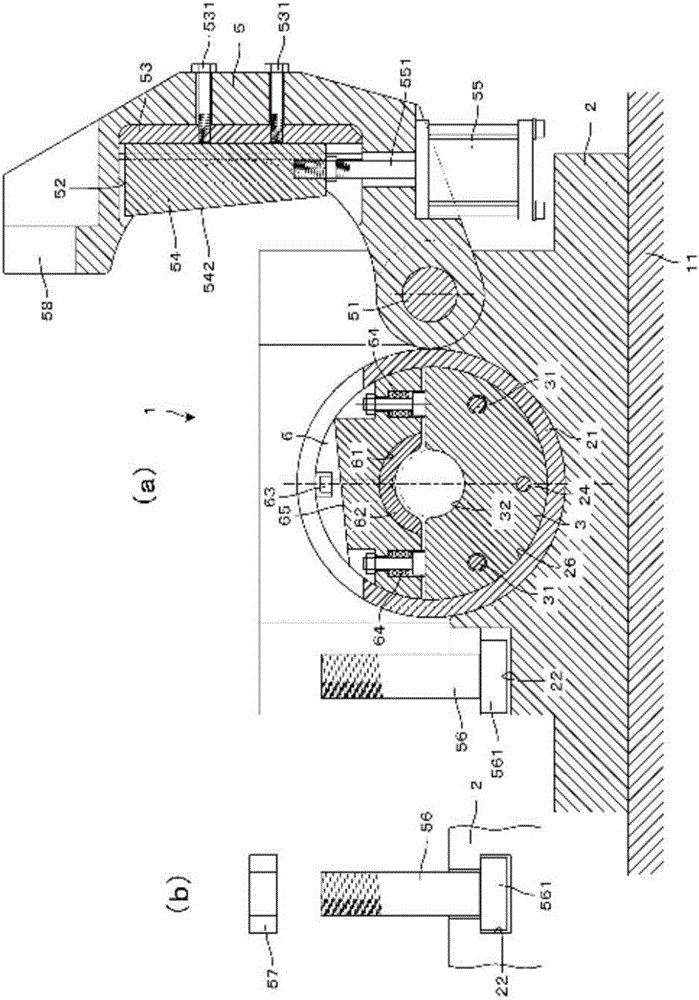

[0036] Embodiments of the present invention will be described below based on the drawings. figure 1 (a) is a longitudinal sectional front view showing a cutting device according to an embodiment of the present invention, figure 1 (b) is the bolt that fixes the clamping rod to the abutment figure 1 (a) Left side view. figure 2 Yes figure 1 The A-A section diagram. image 3 (a) is a longitudinal sectional front view showing a state in which the clamp lever is swung to the replacement position, image 3 (b) is the bolt that fixes the clamping rod to the abutment image 3 (a) Left side view. Figure 4 yes means image 3 (a) is a front view of a longitudinal section in a state where the stationary knife and the pressing member are removed from the abutment. Figure 5 (a) is a front view showing a clamp block and a guide block, Figure 5 (b) is Figure 5 (a) Left side view. Image 6 It is a front view showing the fixed knife and the movable knife.

[0037] like Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com