A method for preparing biomimetic microcapsules from phospholipid bilayer confined organic titanium source and natural pigment

A technology of natural pigments and organic titanium, which is applied in the preparation of microspheres, photosensitive equipment, titanium dioxide, etc., can solve the problems of complicated operation process and lack of functionality, and achieves simple preparation method, strong operability, and cheap and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

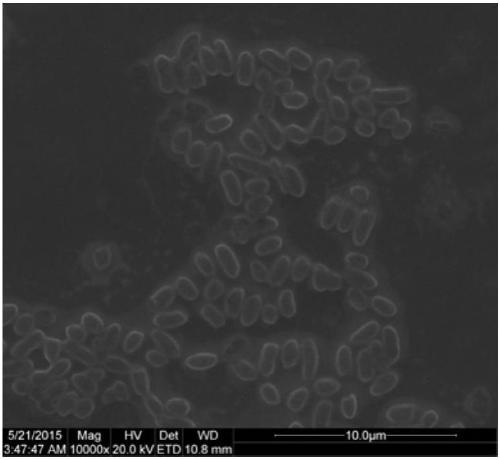

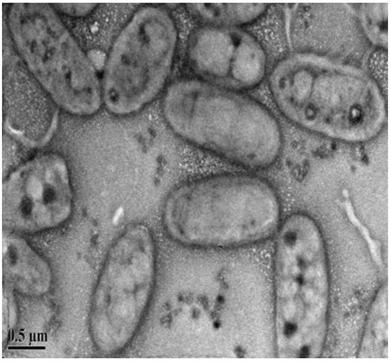

[0022] Add 25mg of cholesterol, 100mg of phospholipids, 0.05mg of tetrabutyl titanate, 0.1mg of natural pigments, and 10mL of chloroform into the flask, and mix them uniformly with ultrasound at room temperature, and remove the chloroform by rotary evaporation at 25°C to obtain a uniform green film. Then add 5 mL of 0.01 mol / L phosphate buffer solution with a pH value of 7 in the flask, use an ultrasonic cleaner to ultrasonically disperse at room temperature for 60 minutes at a frequency of 100 Hz and a power of 100 W, then stir and react at room temperature for 12 hours, and then the reaction product Centrifuge at a speed of 5000 rpm to obtain a green precipitate, wash the green precipitate with a 0.01mol / L phosphate buffer solution with a pH value of 7 until the supernatant is colorless, and then dry it naturally to obtain a green powder, which has photoelectric conversion Functional titanium dioxide biomimetic microcapsules. Depend on figure 1 and 2 It can be seen that th...

Embodiment 2

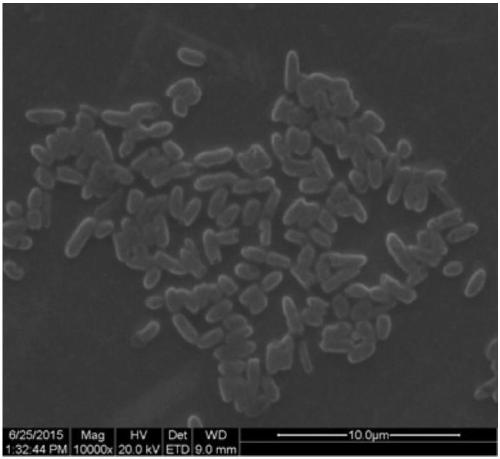

[0024] Add 25mg of cholesterol, 100mg of phospholipids, 0.1mg of tetrabutyl titanate, 0.1mg of natural pigments, and 10mL of chloroform into the flask, and mix them uniformly with ultrasound at room temperature, and remove the chloroform by rotary evaporation at 25°C to obtain a uniform green film. Then add 5 mL of 0.01 mol / L phosphate buffer solution with a pH value of 7 in the flask, use an ultrasonic cleaner to ultrasonically disperse at room temperature for 60 minutes at a frequency of 100 Hz and a power of 100 W, then stir and react at room temperature for 12 hours, and then the reaction product is Centrifuge at a speed of 5000 rpm to obtain a green precipitate, wash the green precipitate with 0.01mol / L phosphate buffer solution with a pH value of 7 until the supernatant is colorless, then dry it naturally to obtain a green powder, which has the function of photoelectric conversion TiO2 biomimetic microcapsules. Depend on image 3 and 4 It can be seen that the obtained ...

Embodiment 3

[0026] Add 25mg of cholesterol, 100mg of phospholipids, 0.15mg of tetrabutyl titanate, 0.1mg of natural pigment, and 10mL of chloroform into the flask, mix them uniformly by ultrasonic at room temperature, remove the chloroform by rotary evaporation at 25°C, and obtain a uniform green film. Then add 5 mL of 0.01 mol / L phosphate buffer solution with a pH value of 7 in the flask, use an ultrasonic cleaner to ultrasonically disperse at room temperature for 60 minutes at a frequency of 100 Hz and a power of 100 W, then stir and react at room temperature for 12 hours, and then the reaction product Centrifuge at a speed of 5000 rpm to obtain a green precipitate, wash the green precipitate with a 0.01mol / L phosphate buffer solution with a pH value of 7 until the supernatant is colorless, then dry it naturally to obtain a green powder, which has photoelectric Titanium dioxide biomimetic microcapsules with transforming functions. Depend on Figure 5 and 6 It can be seen that the tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com