Automatic device for smearing with butyl rubber

An automatic equipment, butyl glue technology, applied in the direction of surface coating liquid device, coating, etc., can solve the problems of low degree of automation, unable to meet production needs, glue coating efficiency and quality can not meet market demand, etc. Achieving the effect of ensuring coating quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

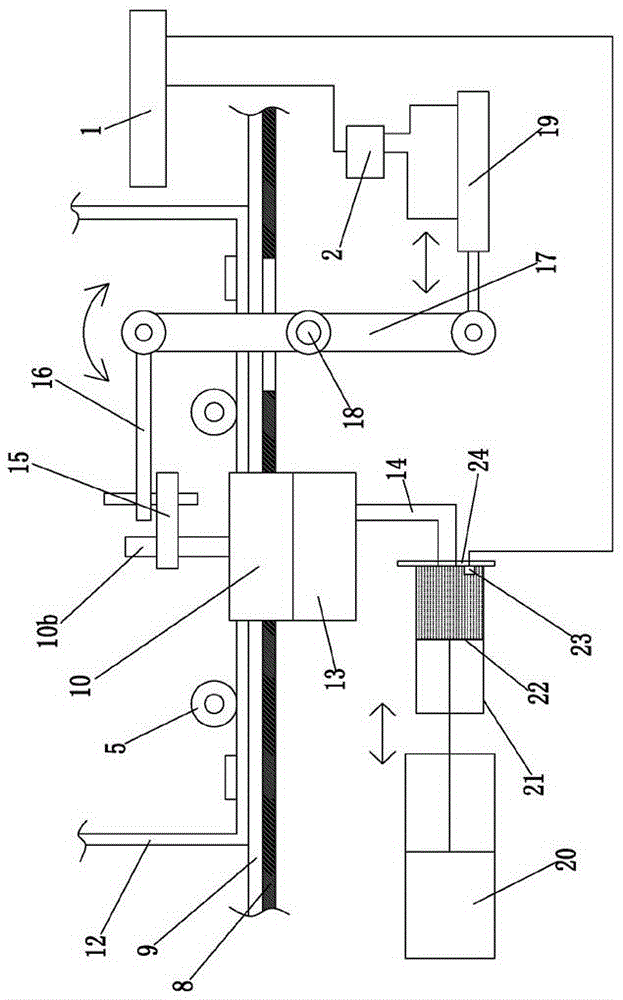

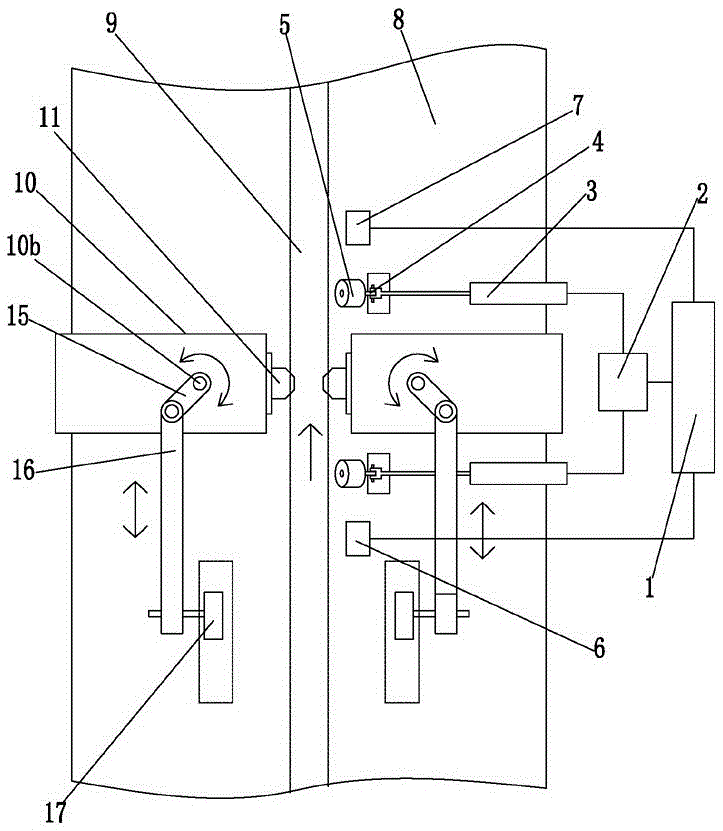

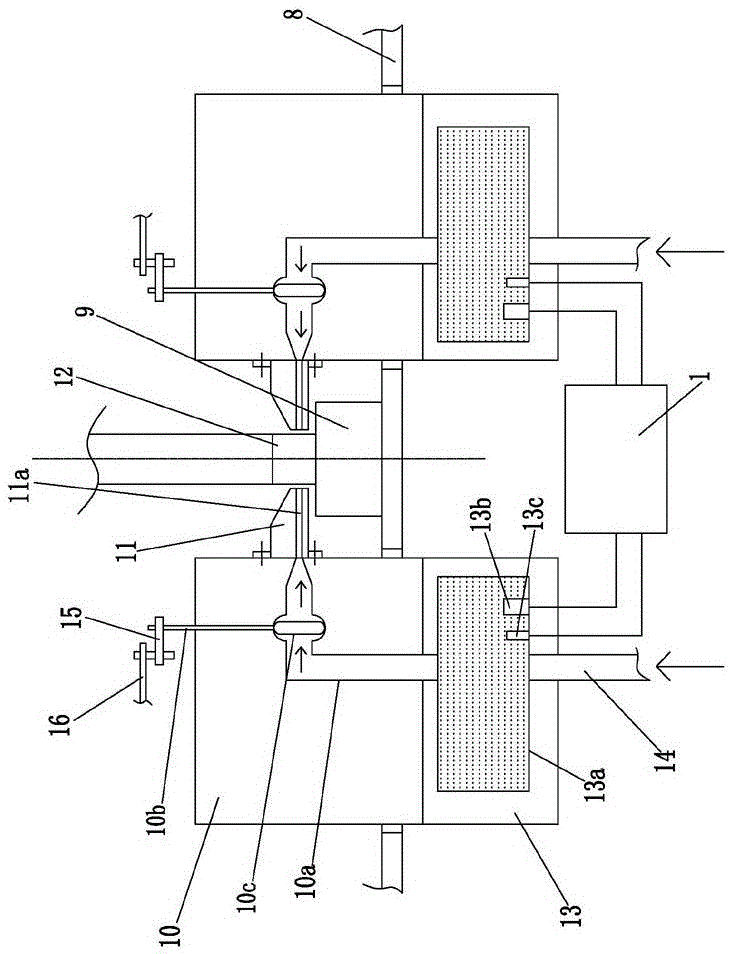

[0021] Such as Figure 1-4 As shown, a kind of automatic equipment for smearing butyl glue, comprises control module 1, the air pressure system 2 controlled by control module 1, frame 8, the movable frame pressing mechanism that is used to press down window frame 12, is used to give Glue-applying seat 10 for gluing window frame 12, heat-insulating seat 13 for insulating butyl rubber, glue delivery system, conveyor line track 9 capable of transporting window frame 12 is installed on frame 8, glue-feeding system, heat preservation seat 13. The glue application seats 10 are arranged sequentially according to the glue delivery sequence.

[0022] Above-mentioned gluing seat 10 comprises glue channel 10a, the opening and closing action mechanism that can control the opening and closing state of glue channel 10a, the gluing nozzle 11 that is installed in the outlet end of glue channel 10a, and gluing nozzle 11 is provided with the coating that can communicate with glue channel 10a ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com