Method for removing steel tube blank tip

A technology of steel pipe and billet end, which is applied in the field of cutting equipment to achieve the effects of slowing impact, improving stability, and improving blanking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] During the specific implementation: a method for removing the end of a steel pipe billet, which is characterized in that the cutting of the end of the steel pipe is realized by water cutting, and the burr generated at the cutting part is removed by using the deformation dispersion of the cutting water flow itself during water cutting wash off.

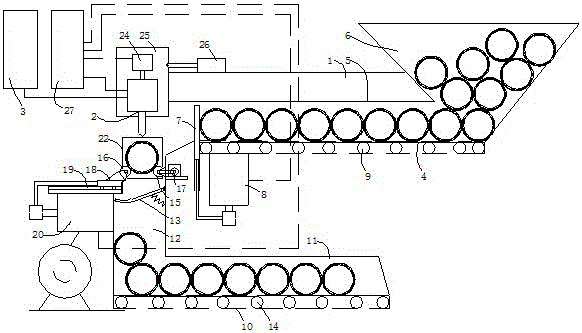

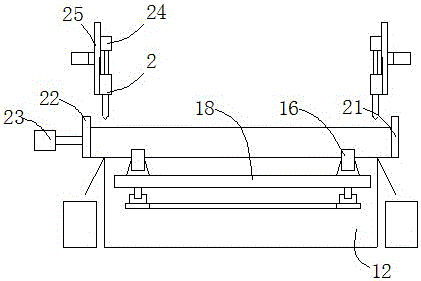

[0039] Specifically, when this method is implemented, the figure 1 and figure 2 A steel pipe end cutting machine shown is realized. The steel pipe end cutting machine includes a frame 1, a feeding part structure, a cutting part structure and a discharging part structure that are installed on the frame 1 and connected in sequence, wherein, The cutting part structure includes a steel pipe positioning device for positioning the steel pipe to be cut and two steel pipe end cutting devices. One side of the steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com