Hollow hydraulic spinner

A spinner and hydraulic technology, applied in the field of oil drilling, can solve the problems of high requirements for blowout preventers, uncontrollable tightening torque, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

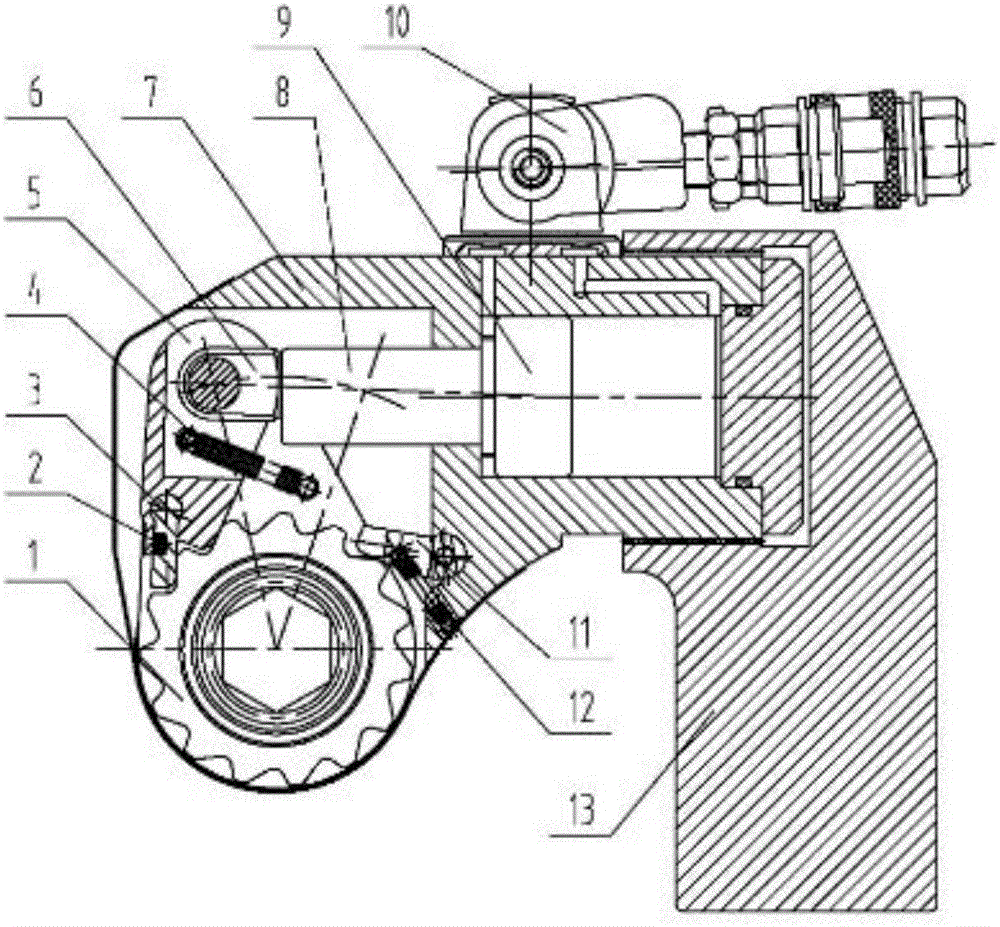

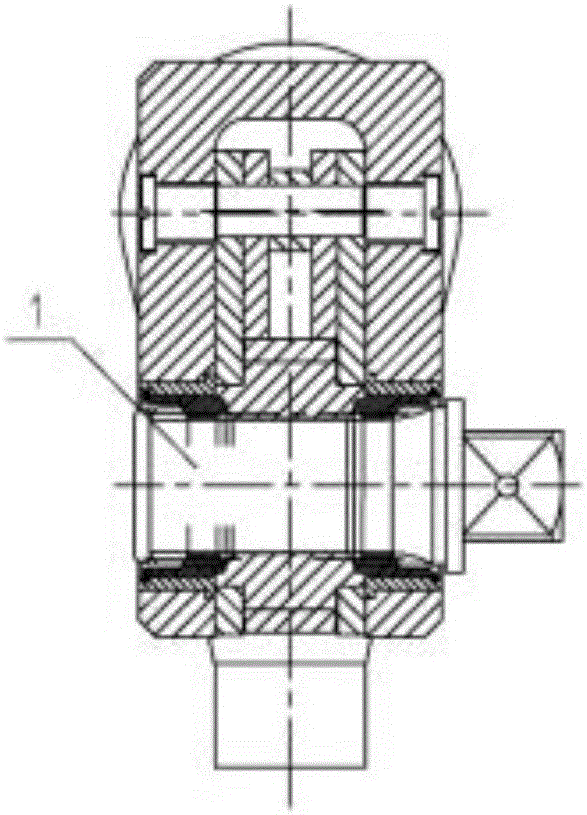

[0016] refer to figure 1 , figure 2 As shown, a hollow hydraulic spinner includes a housing 7, an oil cylinder body, a piston rod 8 and a fork 6 are installed in the housing 7, and a piston 9 is installed in the cylinder body of the piston rod 8, There is a pipeline in the cylinder, one end of the pipeline is connected to the oil inlet and outlet ports at both ends of the piston, the other end of the pipeline is connected and installed on the rotary joint 10 of the cylinder, and the pawl 5 is installed on the fork 6 , the pawl 5 is equipped with a floating pawl 3 and a floating pawl pressure spring 2, a pawl tension spring 4 is installed on the pawl 5, a transmission ratchet and a drive shaft assembly 1, a stopper assembly 1 are installed in the housing 7 Retraction pawl 11 and anti-retraction pawl extension spring 12, reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com