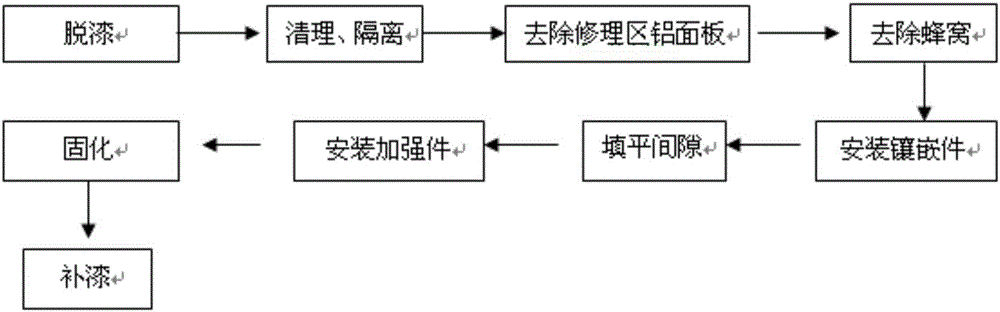

Method for repairing debond of high-density honeycomb block of honeycomb sandwich structure of aluminum deck

A honeycomb interlayer and high-density technology, which is applied in the repair field of debonding of high-density honeycomb blocks in the honeycomb sandwich structure of aluminum panels, can solve the defects that affect the repair quality, debonding, delamination, and affect the bonding of high-density honeycomb blocks and aluminum panels Strength and other issues, to reduce the difficulty of repair, prevent incomplete curing, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

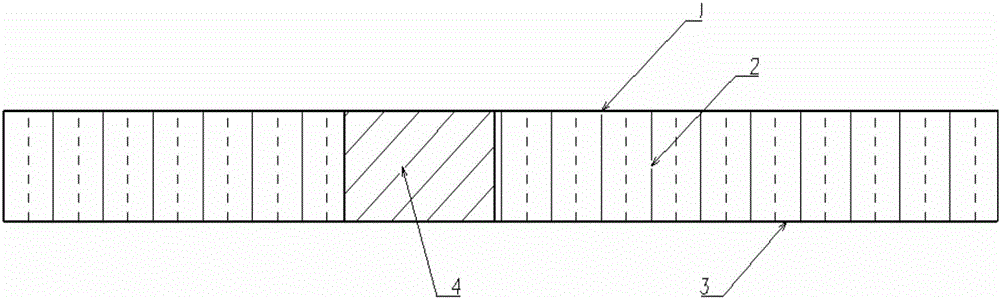

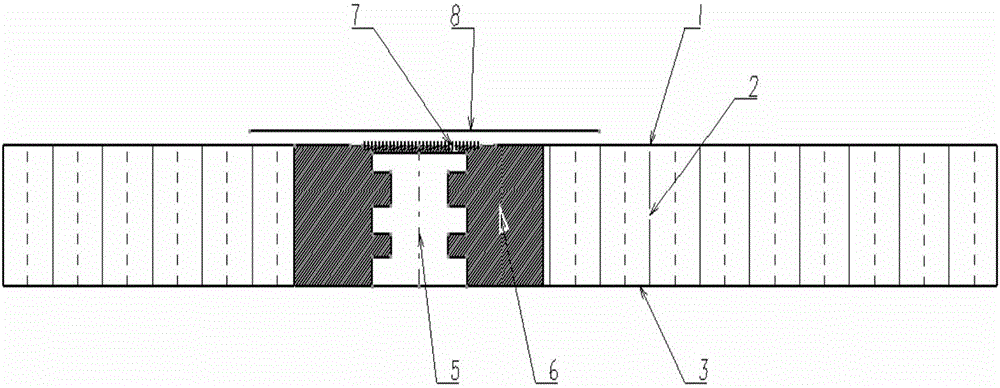

[0035] Pre-repaired disbonded area is diameter high-density honeycomb block,

[0036] 1. Paint removal

[0037] Take the debonded area as the center, remove the paint layer 30mm larger than the edge of the debonded area, and use 180-240# sandpaper to polish the area to be repaired until the metal surface of the aluminum panel (1) is exposed, but the aluminum panel must not be damaged.

[0038] 2. Clean up and isolate

[0039] Wipe the depainted part of the aluminum panel (1) with a clean linen cloth dipped in methyl ethyl ketone until there is no stain on the linen cloth. Protect the area to be repaired, and use tape to isolate and protect the outside of the paint stripped area.

[0040] 3. Remove the aluminum panel in the repair area

[0041] Drill a Φ5.2mm hole in the center of the debonded area of the high-density honeycomb block (4), centering on the hole, remove the aluminum panel (1) there with a drill with the same diameter as the high-density honeycomb block;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com