Manual grooving machine for paperboards

A grooving machine and cardboard technology, applied in paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of high energy consumption, time-consuming and laborious transportation, startup or shutdown, etc., to achieve flexible and reliable operation and good grooving effect. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing of description, the present invention will be further described.

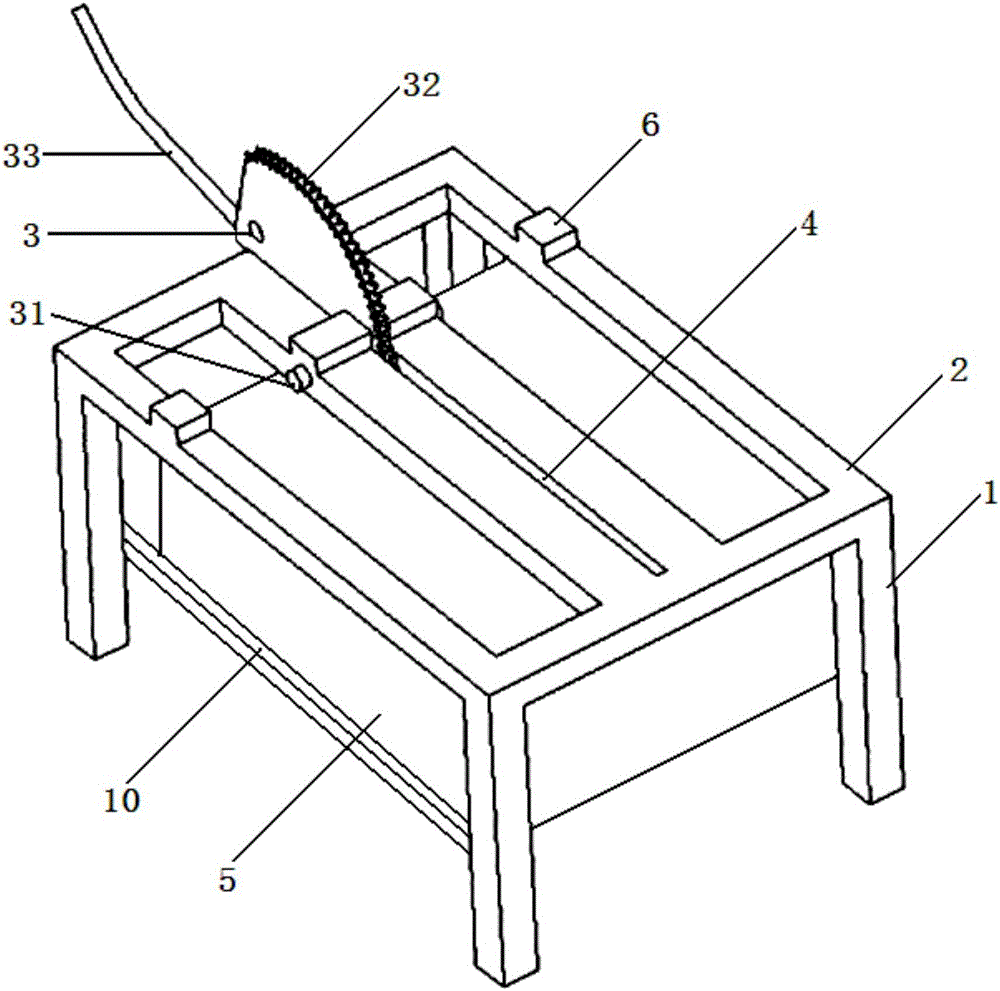

[0019] Such as figure 1 As shown, a cardboard manual grooving machine includes a support 1 and a workbench 2 on the support 1. The workbench 2 is provided with a grooving knife 3, and the grooving knife 3 is connected to the working table through a pin 31. The table 2 can also be manually rotated, and the workbench 2 is provided with a slit 4 corresponding to the edge 32 of the grooving knife 3, and the width of the slit 4 is at least equal to the thickness of the grooving knife 3; the workbench 2 is provided with a scrap box 5, the top opening of the scrap box 5 is distributed directly below the slit 4, and the scrap box 5 is installed in a drawer with the bracket 1 through the slide rail 10 provided on the bracket 1. By providing the paper scrap box 5 installed in a drawer type, it is convenient to effectively collect and uniformly process the paper scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com