Fluid jet device and control system thereof

A control system and fluid injection technology, applied in printing devices, printing, etc., can solve problems affecting printing quality, entering air, increasing ink cartridge costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will now be described in conjunction with the accompanying drawings.

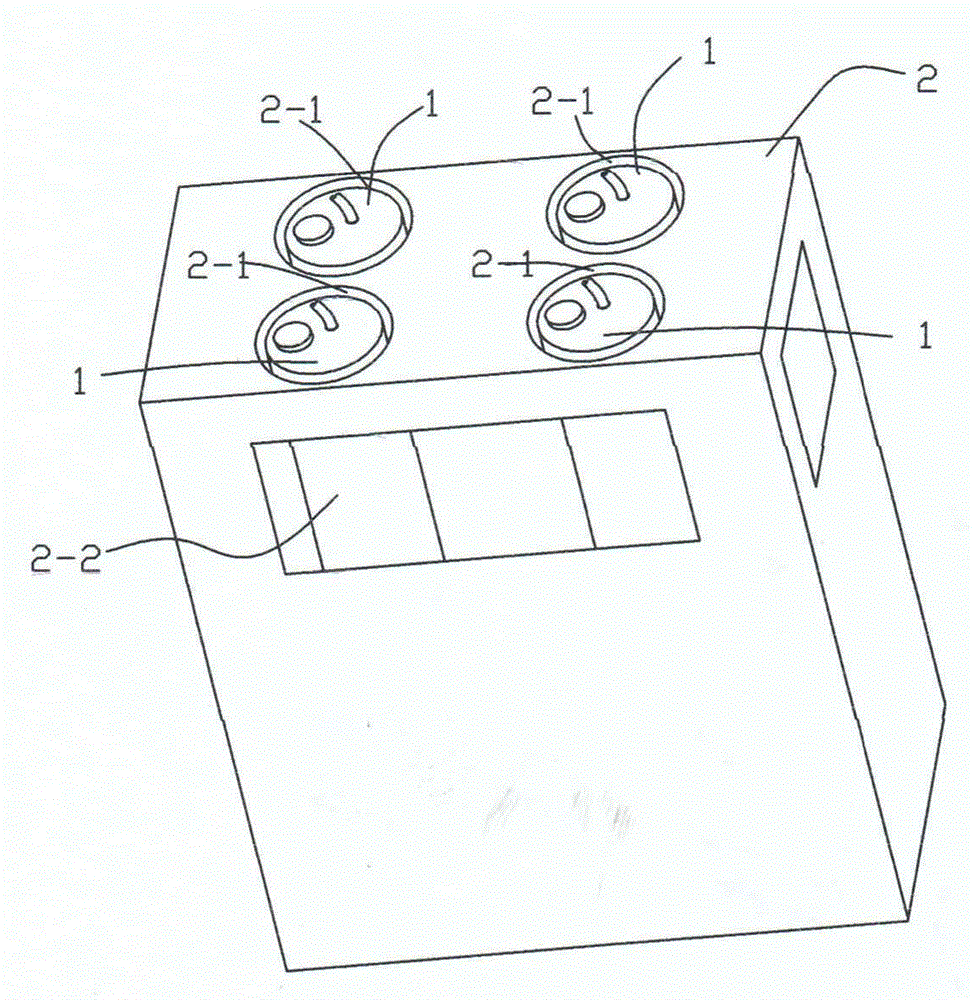

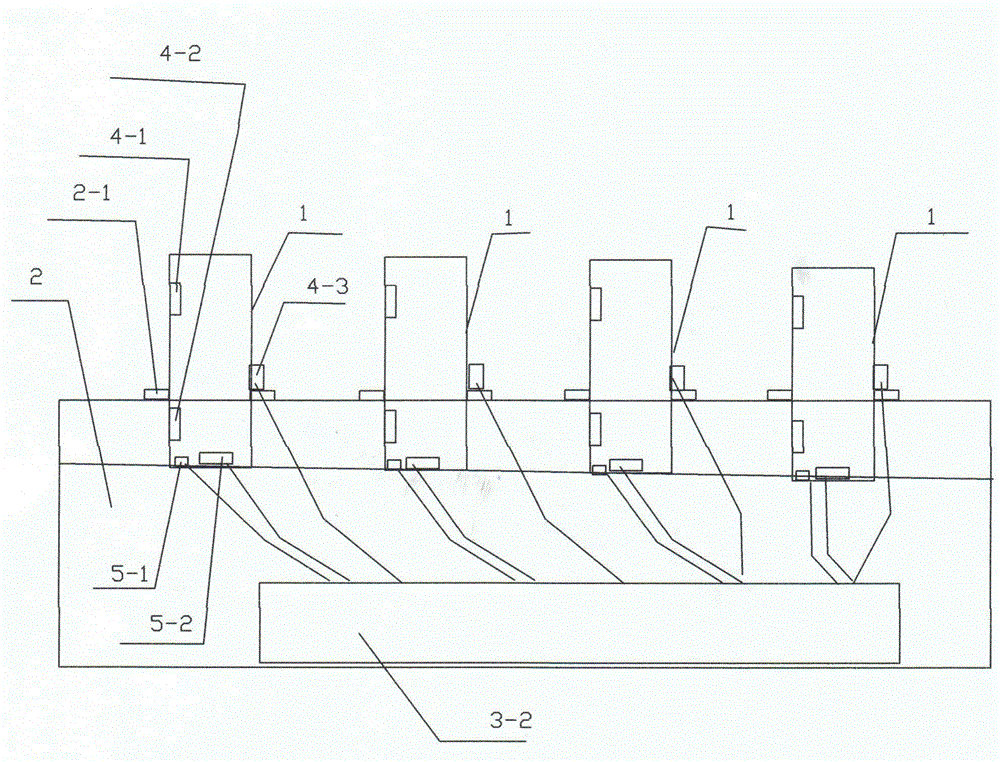

[0017] figure 1 It is a schematic diagram of the first preferred embodiment of the fluid injection device and its control system of the present invention. Such as figure 1 As shown, the centralized ink supply device with a constant temperature system, sound and light prompting equipment and an oscillator includes several ink bottles 1, a box body 2 for accommodating the ink bottles, and the box body is divided into upper and lower parts. layer, the upper layer of the box is provided with several grooves 2-1 for accommodating the ink bottles, the lower layer is used to store the oscillator, the oscillator includes an oscillation generator 3-1 and a control circuit board 3-2, and several ink bottles The bottom of the bottle 1 is close to the upper surface of the upper and lower separation layer of the box body 2, and the vibration generator 3-1 is close to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com