Rear torsion beam structure of automobile

A technology for torsion beams and automobiles, which is applied to vehicle components, interconnection systems, suspensions, etc., can solve the problems of large occupied space and complicated platform design, and achieve the effect of reducing occupied space, reducing adjustment difficulty and convenient layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

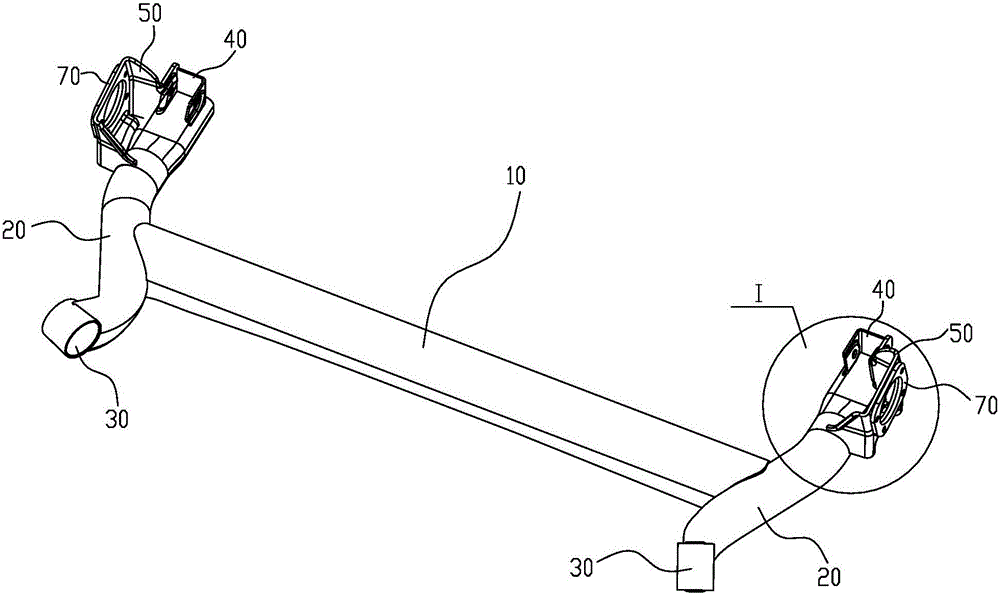

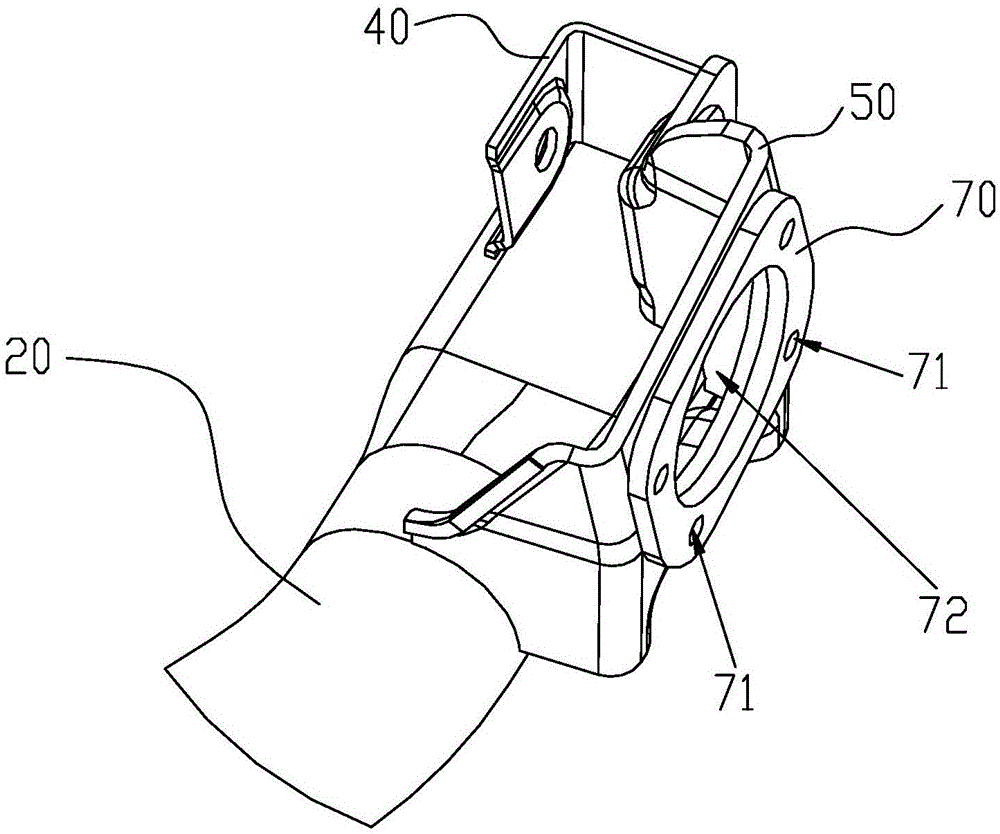

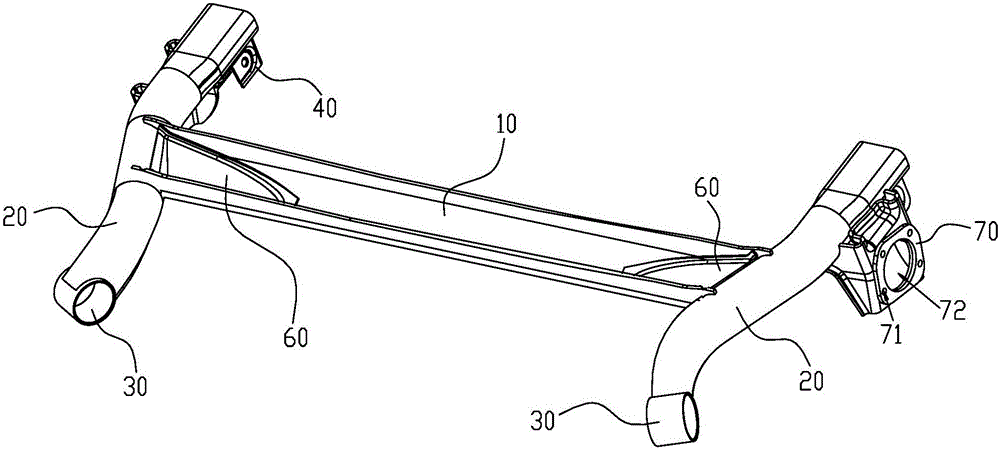

[0012] A car rear torsion beam structure, such as Figure 1-3 As shown, the crossbeam 10 is included, the two ends of the crossbeam 10 are respectively provided with a longitudinal beam 20, one end of the longitudinal beam 20 is provided with a bush sleeve 30, and the other end is provided with a shock absorber bracket 40, the beam body of the longitudinal beam 20 is close to the shock absorber A hub bracket 50 is provided at the position of the shock bracket 40 , and the cross-section of the beam 10 is U-shaped with the opening facing downward, and the cross-sectional area of the beam 10 gradually increases symmetrically from the middle to both ends. The beam 10 with a U-shaped transverse section is selected, so that the torsional stress of the beam 10 can be dispersed, and the difficulty of adjusting the torsional stiffness is greatly reduced, which is not only beneficial to product development and design, but also ensures that the torsional stiffness and shear center posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com