Disc-type linear cutter winding device allowing locations of winding rollers to be adjustable

A winding device, disc-type technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problem that the winding work cannot be carried out smoothly, the winding roller cannot be aligned with the strip, and cannot be easily Good realization of winding and other issues, to achieve the effect of realizing winding operation, preventing displacement and jumping, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

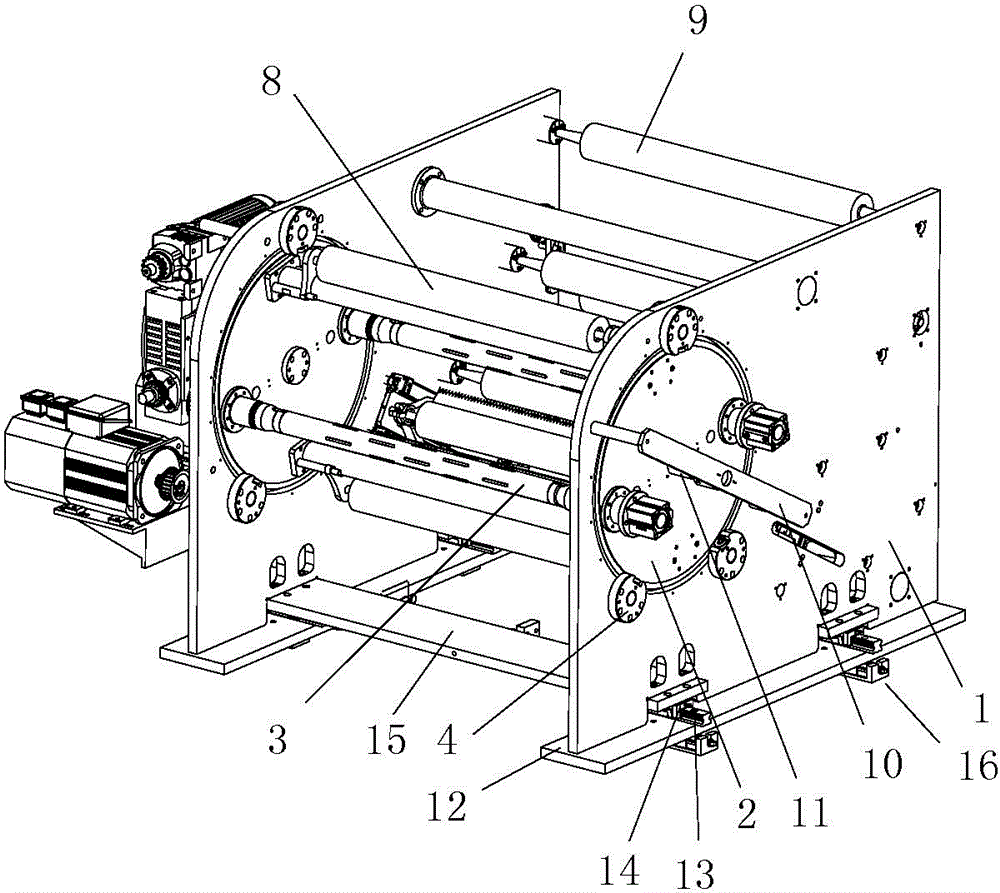

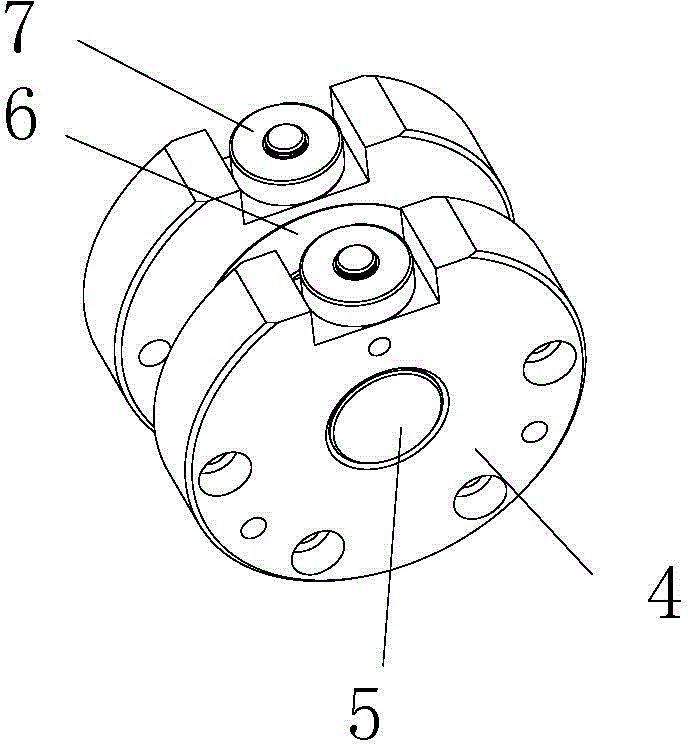

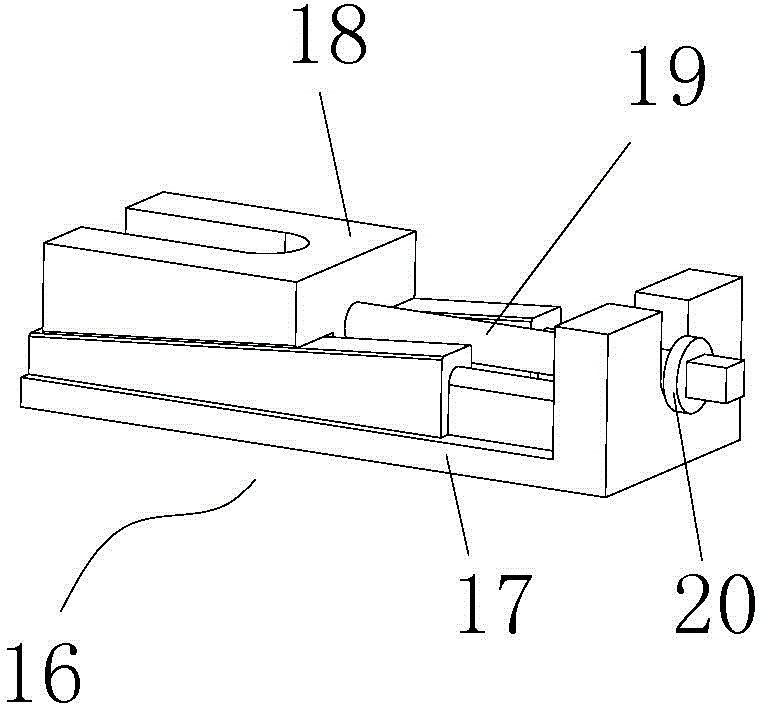

[0034] like figure 1As shown, it is a structural schematic diagram of an embodiment of a disc-type linear cutter winding device with an adjustable winding roller position in the present invention. The disc-type linear cutter rewinding device with adjustable rewinding roller position in this embodiment includes two brackets 1 located at both ends. The two brackets 1 are correspondingly provided with coaxial mounting holes, and the mounting holes are provided with a Disc-type roller stands 2 with gap fit, and two winding rollers 3 that are rotatably matched with the two disc-type roller stands 2 are arranged between them. The support 1 is provided with a rotating support unit for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com