Continuous material collection device of coating machine

A technology of splicing device and coating machine, which is used in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of reducing production efficiency and waste of substrates, and achieves guaranteed tension, compact structure, and stable rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the drawings and examples, but the embodiments of the present invention are not limited thereto. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, well-known methods, procedures, and components have not been described in detail so as not to unnecessarily obscure the embodiments.

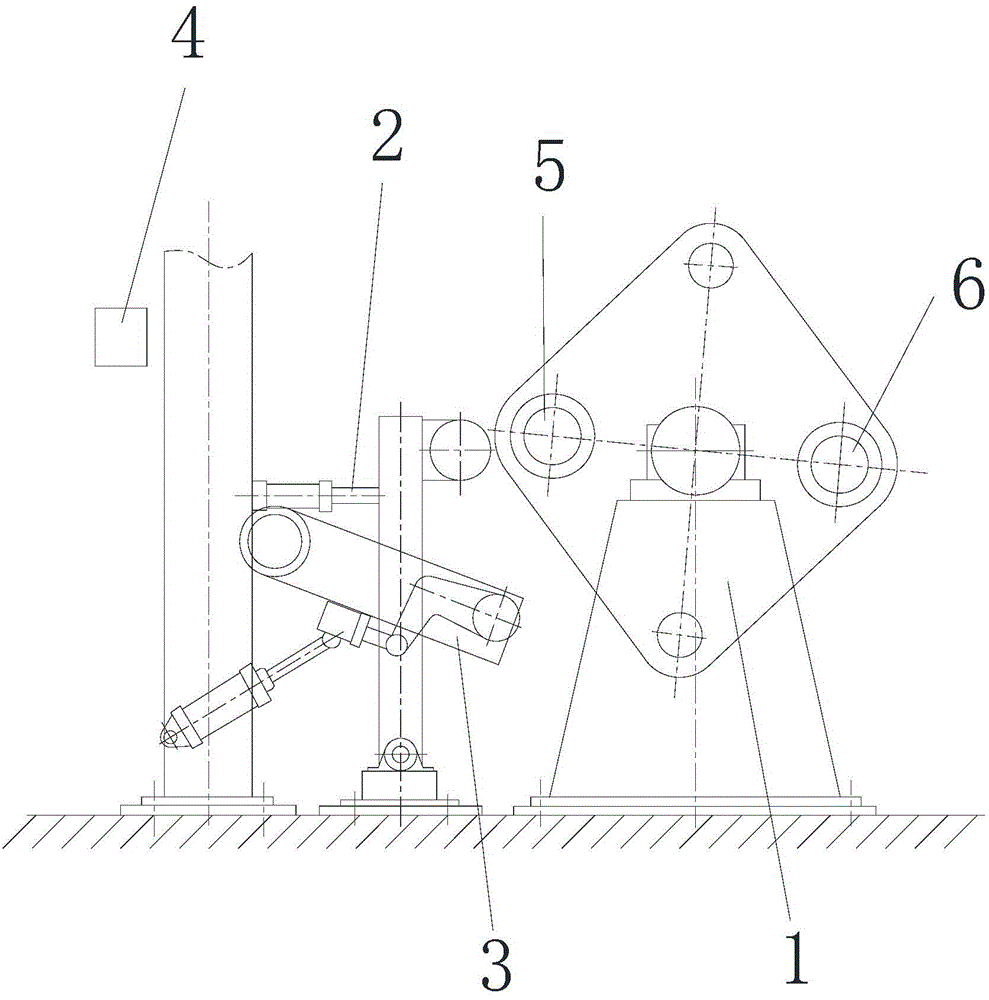

[0010] figure 1 The structure of the continuous material receiving device of the coating machine according to one embodiment of the present invention is schematically illustrated. Such as figure 1 The continuous feeding device of the coating machine shown includes a double roll rotary unwinding rack 1, a new roll accelerating device 2, a feeding device 3 and a tension d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap