Manufacturing process of glass melting

A manufacturing process and glass melting technology, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of incomplete glass melting and molding, low degree of process continuity, high glass breakage rate, high cost rate, The effect of good uniformity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

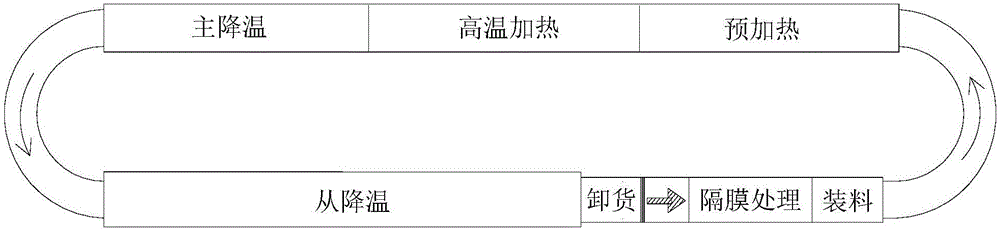

[0017] Such as figure 1 Shown, a kind of glass fusion manufacturing process is characterized in that, described process step is:

[0018] (1) Evenly coat the inner wall of the mold with diaphragm paint to complete the diaphragm treatment;

[0019] (2) glass workpiece is packed in the mold in step (1);

[0020] (3) the mold that described glass workpiece is housed is placed on the transmission mesh belt that advances at a constant speed;

[0021] (4) The transmission mesh belt sends the mold equipped with the glass workpiece into the preheating zone, the heating temperature is 10°C-500°C, and the mold and the glass workpiece in the mold are evenly heated by adopting a uniform heating method from top to bottom;

[0022] (5) The transmission mesh belt sends the mold processed in step (4) and the glass workpiece in the mold to the high-temperature heating zone. The heating temperature is 500°C-1713°C, and the method of uniform heating up and down is adopted until the glass workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com