Device for realizing aging of hard wire coiled rod by applying pulse current and treatment method

A technology of pulse current and pulse power, which is used in heat treatment furnaces, heat treatment equipment, furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

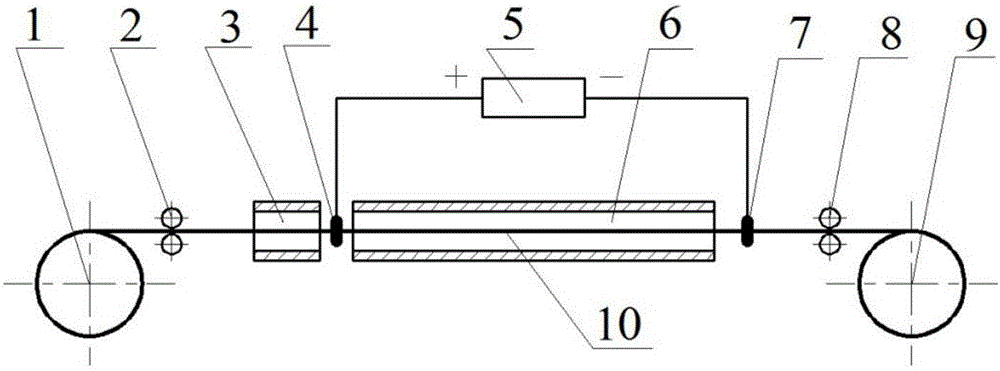

Embodiment 1

[0022] The hard line wire rod of this embodiment is SWRH82B, its specification is Φ8mm, chemical composition (mass fraction / %) is 0.82C, 0.26Si, 0.76Mn, 0.0010S, 0.0009P, 0.30Ni, 0.30Cr, and the rest is Fe. The hot-rolled coil is placed on the uncoiling device, and then the wire rod passes through the pinch roll, the tubular preheating furnace, the electrode, the tubular soaking furnace, the electrode, the lead-in roll, and enters the winding device. After that, turn on the power supply of the preheating furnace to preheat the wire rod entering the preheating furnace. When the preheating temperature reaches 260°C, turn on the power supply of the winding device, and the wire rod moves in the winding direction to start winding; Soaking furnace power supply and pulse power supply, conduct soaking and electric pulse treatment on the wire rod entering the soaking furnace to ensure that the temperature of the wire rod is 260°C and its running time in the soaking furnace is 420s (real...

Embodiment 2

[0026] The hard wire rod of this embodiment is SWRH77B, its specification is Φ12mm, chemical composition (mass fraction / %) is 0.78C, 0.22Si, 0.70Mn, 0.0009S, 0.0009P, 0.26Ni, 0.25Cr, and the rest is Fe. The hot-rolled coil is placed on the uncoiling device, and then the wire rod passes through the pinch roll, the tubular preheating furnace, the electrode, the tubular soaking furnace, the electrode, the lead-in roll, and enters the winding device. Afterwards, turn on the power supply of the preheating furnace to preheat the wire rod entering the preheating furnace. When the preheating temperature reaches 320°C, turn on the power supply of the winding device, and the wire rod moves in the winding direction to start winding; Soaking furnace power supply and pulse power supply, conduct soaking and electric pulse treatment on the wire rod entering the soaking furnace to ensure that the temperature of the wire rod is 320°C and its running time in the soaking furnace is 510s (realized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com