Method for eliminating residual stress of hot-rolled strip steel in high-temperature state

A hot-rolled strip steel, high-temperature state technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high heating and cold processing costs, large investment in heat treatment equipment, straightening equipment, high investment costs, etc., to achieve The effect of reducing equipment investment, shortening storage time, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

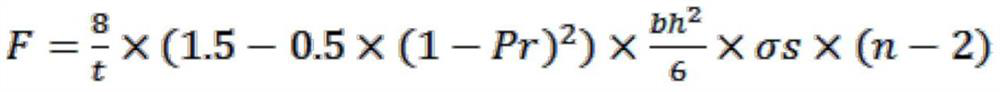

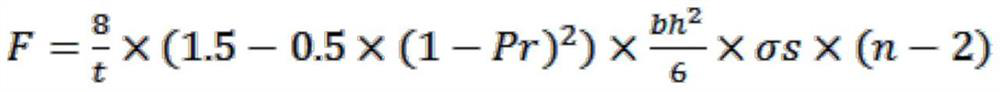

[0088] In this embodiment, the steel grade of the hot-rolled strip steel is ordinary carbon steel Q235B, and the product specification is 2.5mm (thickness)×1250mm (width).

[0089] The physical parameters are as follows in Table 3

[0090] Table 3 Physical parameters of high temperature hot rolled strip

[0091]

[0092] The parameters of the online thermal straightening unit to be installed are shown in Table 4.

[0093] Table 4 Parameters of high temperature straightening unit

[0094]

[0095] After the laminar cooling process and before the coiling process in the hot-rolled strip production line, install an 11-roll straightening machine with a roll diameter of 305 mm and a hot straightening force of 3.34 tons (which can replace the off-line straightening unit with a cold straightening force of 4.94 tons). ) for online control of residual stress in hot-rolled strips.

[0096] In this embodiment, compared with the conventional cold straightening method, the comprehe...

Embodiment 2

[0098] In this embodiment, NM400 wear-resistant steel plate is produced, and the product specification is 12×2000mm. The physical parameters are as follows in Table 5

[0099] Table 5 Physical parameters of high temperature hot rolled strip

[0100]

[0101] The parameters of the online thermal straightening unit to be installed are shown in Table 6

[0102] Table 6 Parameters of high temperature straightening machine

[0103]

[0104] In this embodiment, after the laminar flow process and before the coiling process of the hot-rolled strip production line, a 5-roll straightening machine is installed, the roll diameter is 662 mm, and the hot straightening force is 41.66 tons (the alternative cold straightening force is 127.81 tons). off-line straightening unit), which is used to realize on-line control of residual stress of hot-rolled strip.

[0105] In this embodiment, compared with the conventional cold straightening method, the comprehensive investment cost of equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com