A modular tool-type overhead transport channel and assembly method

A transportation channel and assembly method technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of affecting the quality of reinforced concrete floors, many uncontrollable factors, loss of thickness of protective layer, etc., and achieve safe and reliable transportation channels. , The effect of protection from damage and increased turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

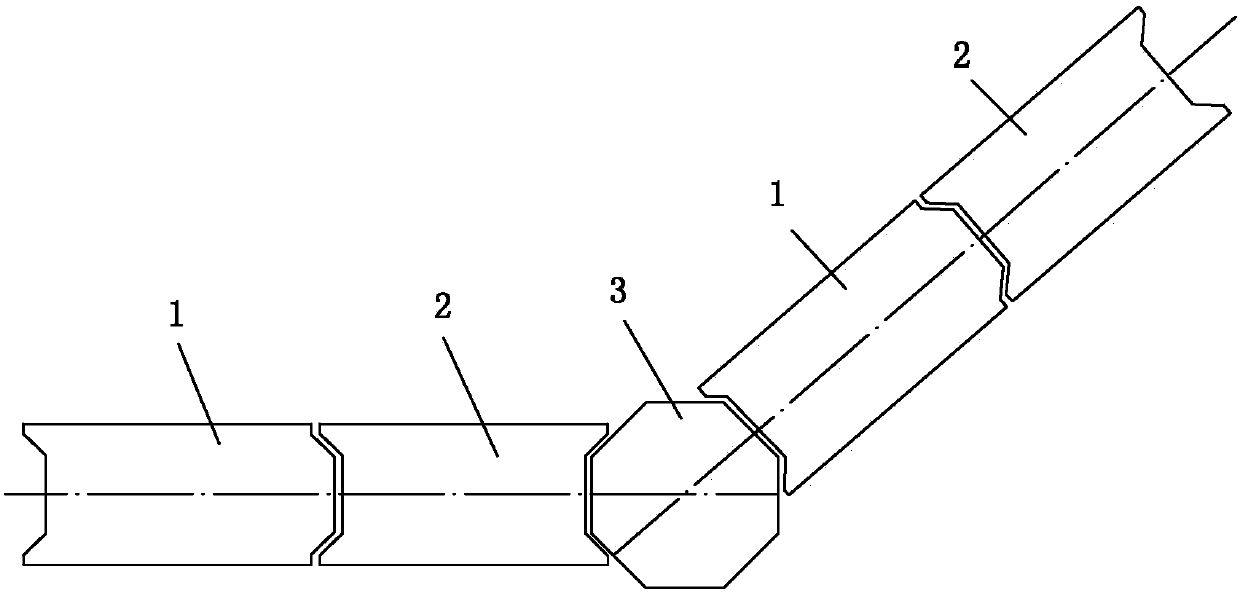

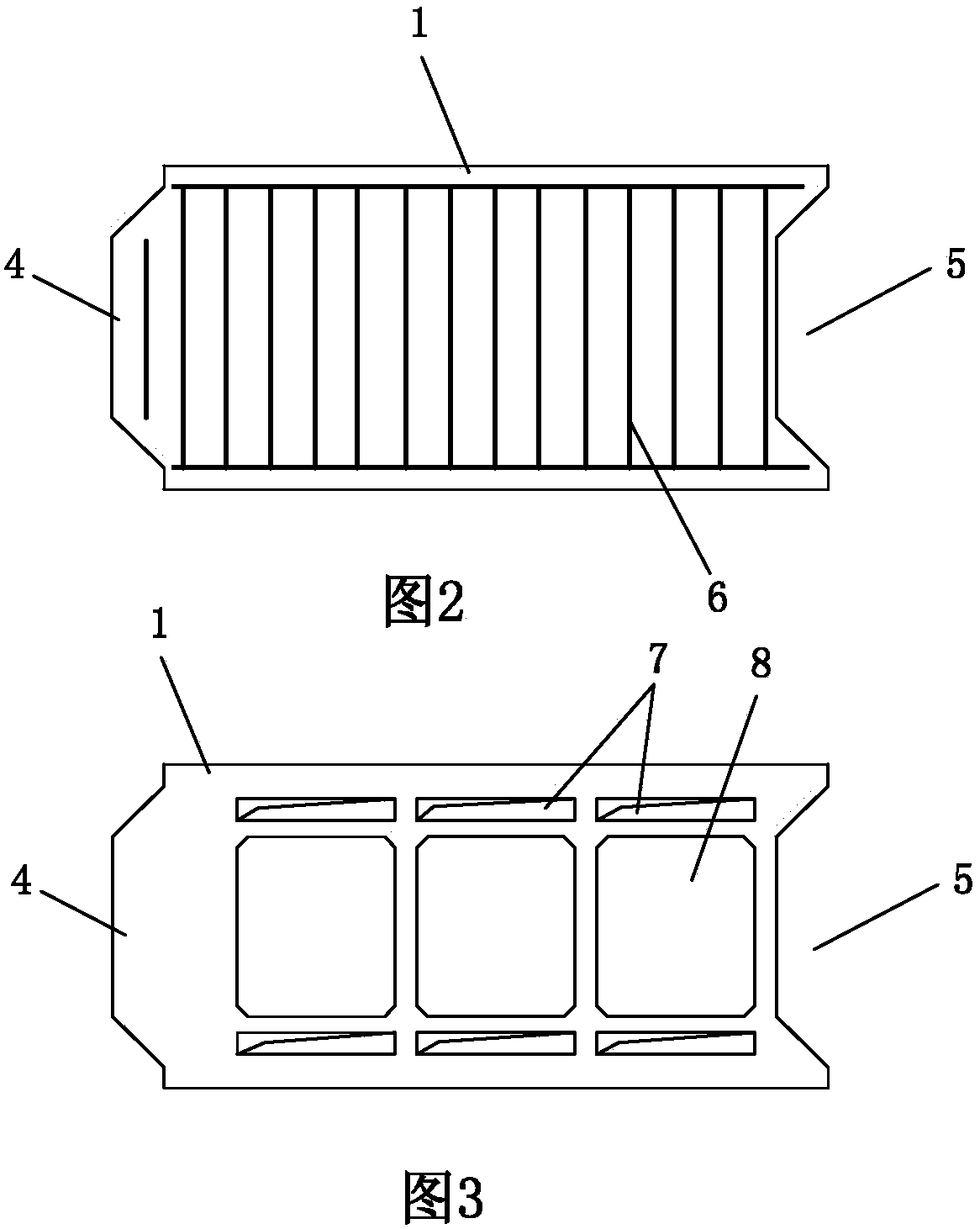

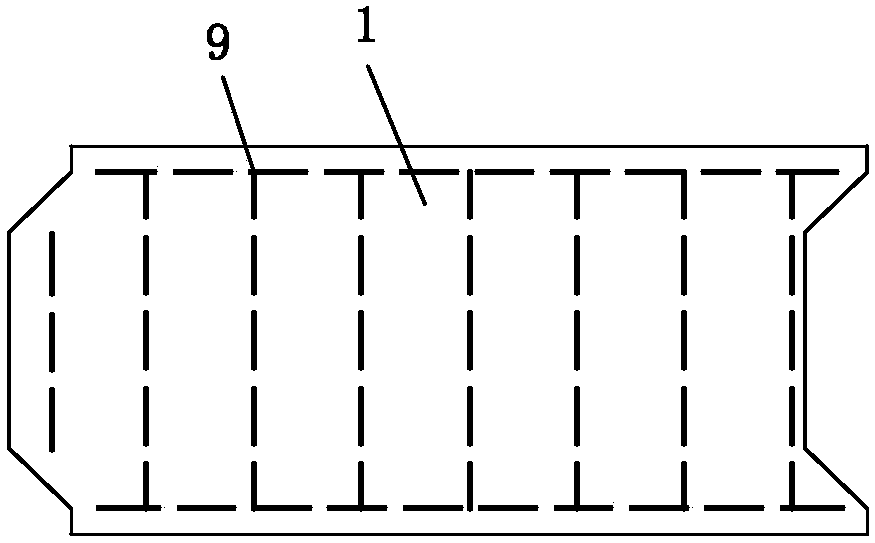

[0030] Embodiment 1: A kind of modularized tool type overhead transportation channel, such as Figure 1-Figure 9 As shown, it includes several spliced flat basic units I1, several spliced flat basic units II2 and several adapter plates 3, one end of the spliced flat basic unit I1 is provided with a convex buckle 4, and the other end of the spliced flat basic unit I is An inner groove 5 cooperating with the convex buckle is provided, and both ends of the spliced plate basic unit II 2 are provided with an inner groove 5 cooperating with the convex buckle, and the convex buckle 4 and the inner groove 5 are equivalent to a male The female groove can realize docking, and the bottom surface of the spliced flat basic unit I and spliced flat basic unit II is provided with 3 pairs (6) of support legs 10, and the convex buckle and the inner groove are both isosceles trapezoidal , the adapter plate 3 is a regular octagonal structure that can be matched with the inner groove...

Embodiment 2

[0035] Embodiment 2: A method for assembling a modular tool-type overhead transport passage as described in Embodiment 1, comprising the following steps:

[0036] A. On the installation ground, first set up the same number of mounting holes as the number of supporting legs, so that the support rod is located in the mounting hole, the fixing nut is located outside the mounting hole, and the height of the supporting legs can be adjusted by rotating the fixing nut;

[0037] B. Splicing straight passage: The convex buckle of splicing flat basic unit Ⅰ is used to connect with another splicing flat basic unit Ⅰ or the inner groove of splicing flat basic unit II, without leaving any seam in the middle, and the butt splicing is determined according to the length of the transportation channel required The number of flat basic units I and the number of spliced flat basic units II,

[0038] C. When turning is required, use an adapter plate between the two straight passages to connect w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com