Peak regulation energy storage system for condensed steam type turbine unit and operation adjusting method

A steam turbine unit, condensing steam technology, applied in the direction of steam engine devices, mechanical equipment, machines/engines, etc., can solve the problems of inconsistent heat supply demand, large steam extraction, and deep peak-shaving function of the unit without consideration, etc. To achieve the effect of alleviating the thermal and electrical contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

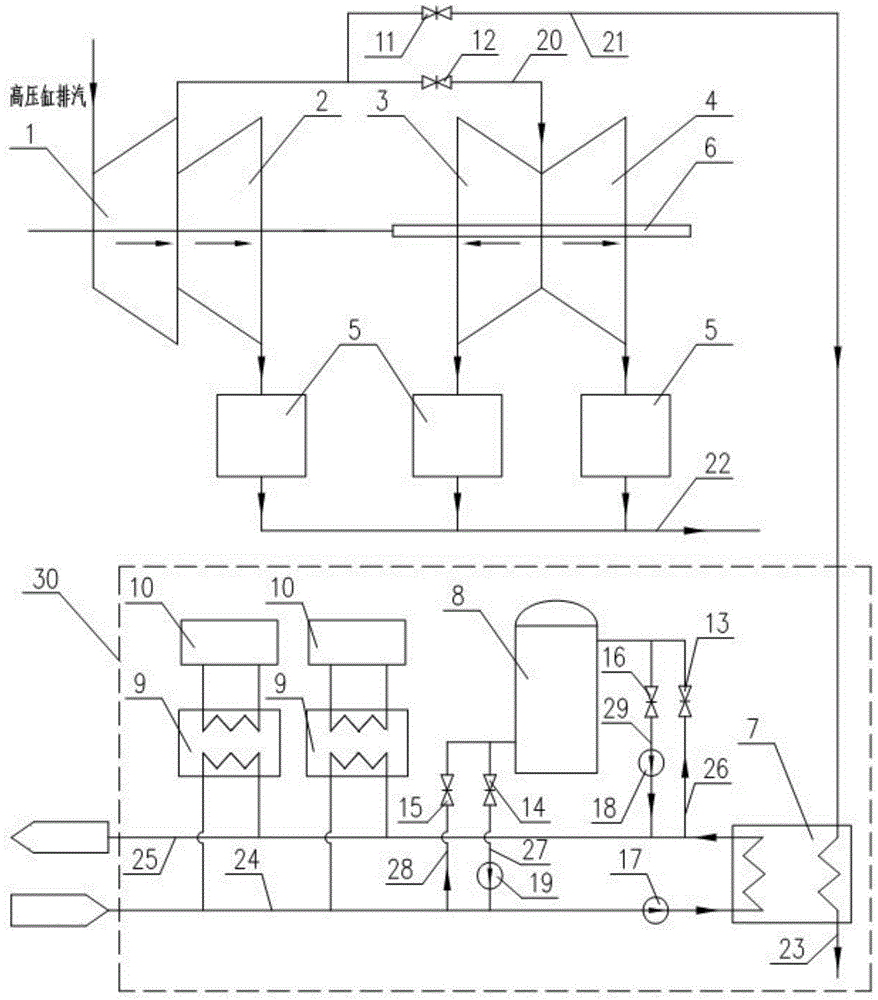

[0042] like figure 1 As shown, the peak shaving energy storage system of the condensing steam turbine unit in this embodiment is composed of a steam turbine low-pressure cylinder optical axis rotor unit and a heat storage and discharge device 30 .

[0043] The steam turbine low-pressure cylinder optical axis rotor unit includes medium-pressure cylinder 1, first low-pressure cylinder 2, low-pressure cylinder steam guide pipe 20, low-pressure cylinder steam guide pipe extraction branch pipe 21, second low-pressure cylinder 3, third low-pressure cylinder 4, condensing steam Device 5, condensation water pipe 22 and optical axis rotor 6. The medium pressure cylinder 1, the first low pressure cylinder 2, the second low pressure cylinder 3, the third low pressure cylinder 4 and the optical axis rotor 6 are coaxially connected; the exhaust port of the medium pressure cylinder 1 is connected with the steam guide pipe 20 of the low pressure cylinder; the second low pressure cylinder 3 ...

Embodiment 2

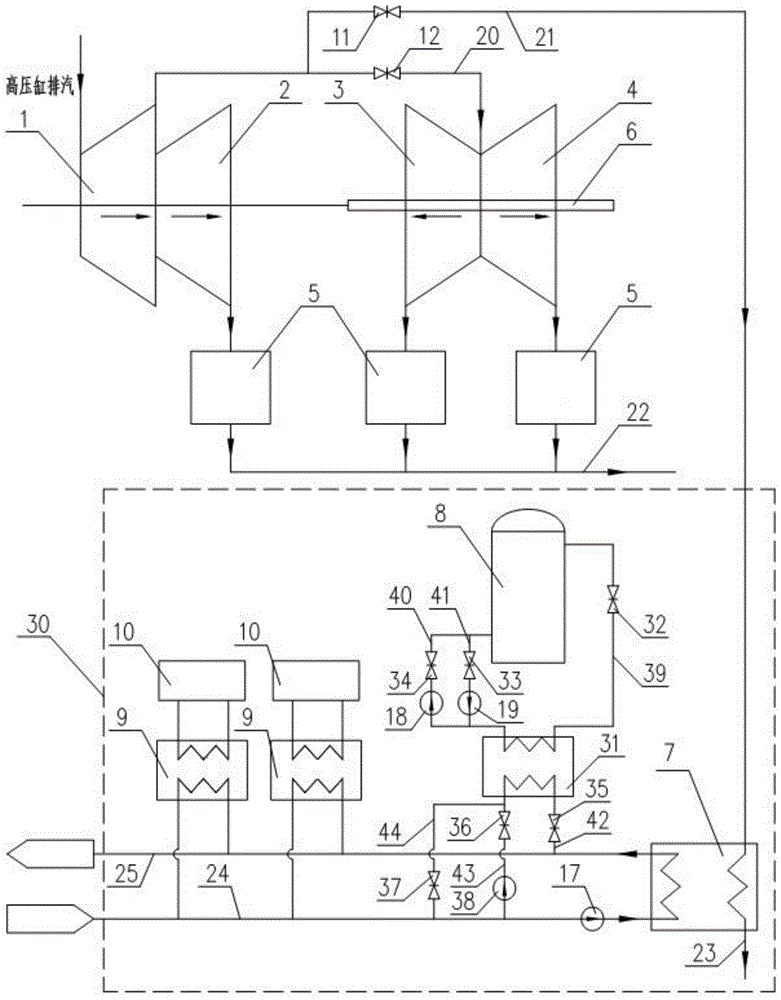

[0067] like figure 2 As shown, this embodiment is composed of a steam turbine low-pressure cylinder optical axis rotor unit and a heat storage and release device 30 .

[0068] The steam turbine low-pressure cylinder optical axis rotor unit includes medium-pressure cylinder 1, first low-pressure cylinder 2, low-pressure cylinder steam guide pipe 20, low-pressure cylinder steam guide pipe extraction branch pipe 21, second low-pressure cylinder 3, third low-pressure cylinder 4, condensing steam Device 5, condensation water pipe 22 and optical axis rotor 6. The medium-pressure cylinder 1, the first low-pressure cylinder 2, the second low-pressure cylinder 3, the third low-pressure cylinder 4 and the optical axis rotor 6 are coaxially connected; the exhaust port of the medium-pressure cylinder 1 is connected to the steam guide pipe 20 of the low-pressure cylinder; The steam inlets of the cylinder 3 and the third low-pressure cylinder 4 are connected with the steam guide pipe 20 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com