Preheating catalytic-oxidation device with burner starting for coal mine ventilation air methane

A catalytic oxidizer and burner technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of large TFRR resistance loss, high maintenance cost, high fan energy consumption, etc., to reduce volume and floor space, Effects of improving operation economy and improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

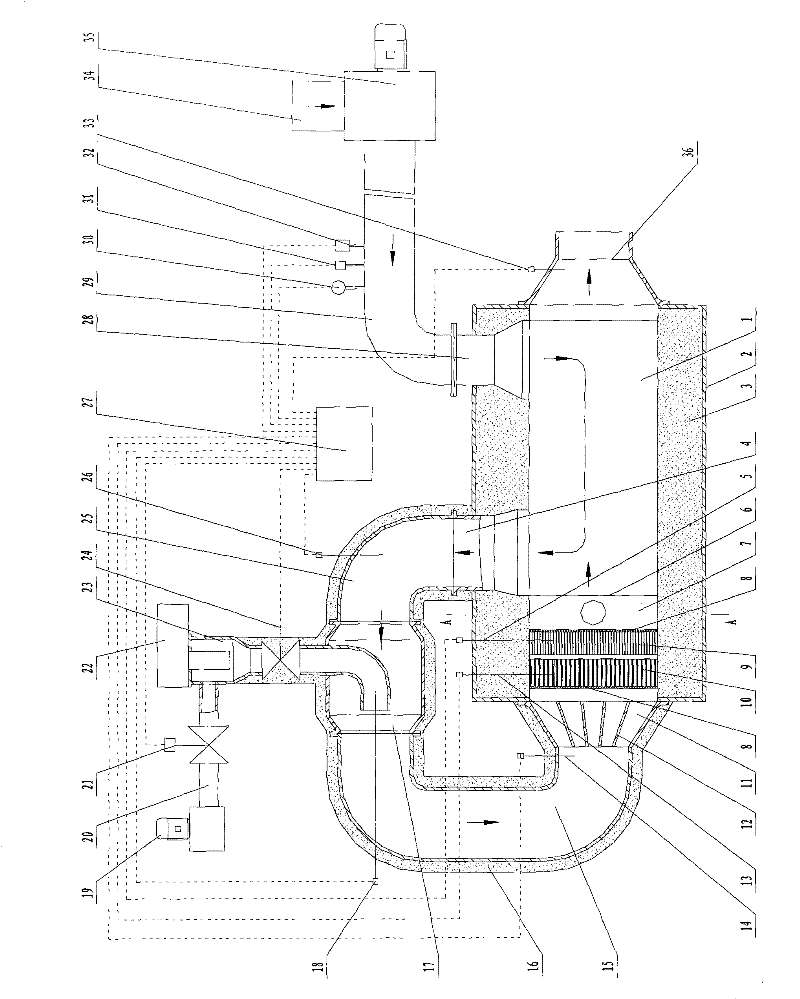

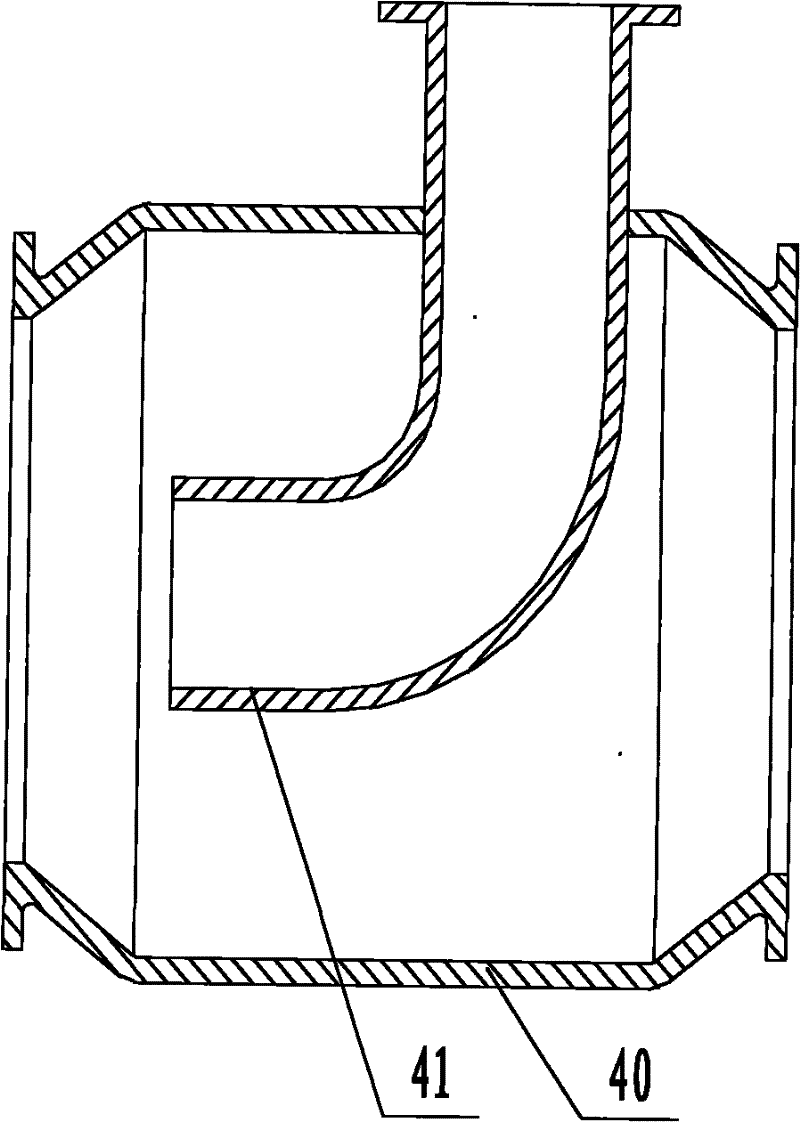

[0030] exist Figure 1-4 In the shown embodiment: coal mine exhaust air preheating catalytic oxidizer with burner start, including exhaust air supply system, preheater 1 and reaction chamber 7 arranged in shell 2, burner heating start system , air intake system, heat extraction system and measurement and control system, of which:

[0031] The exhaust air supply system includes a first exhaust air conveying pipeline 29, a second exhaust air conveying pipeline 34 and a main fan 35, wherein one end of the second exhaust air conveying pipeline 34 communicates with the exhaust exhaust outlet of the mine, and the other end passes through the main fan. 35 is connected to the first exhaust air conveying pipeline 29;

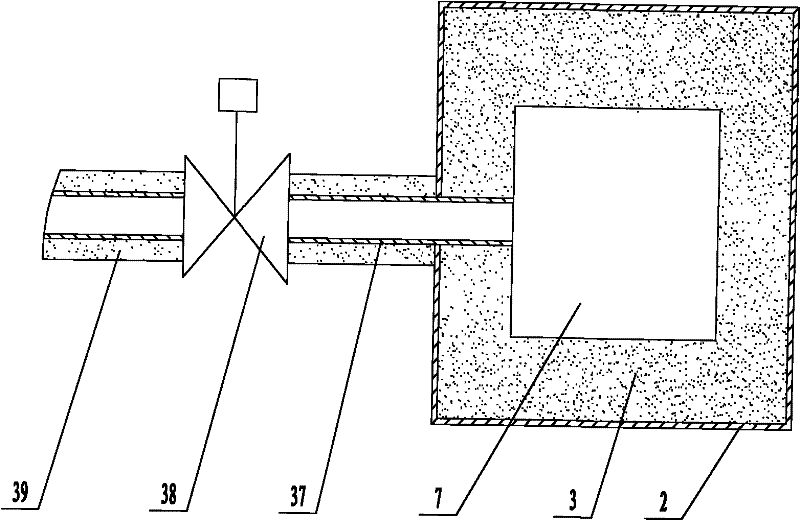

[0032] The inner wall of the housing 2 is provided with a first thermal insulation layer 3, the preheater 1 adopts a partitioned air-air heat exchanger, and the exhaust air inlet 28 of the preheater passes through the first thermal insulation layer 3 and extends to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com