Bearing Module

A technology of valves and internal combustion engines, which is applied in the direction of engine components, machines/engines, casings, etc., and can solve problems such as increasing manufacturing consumption and manufacturing costs, and the impact of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

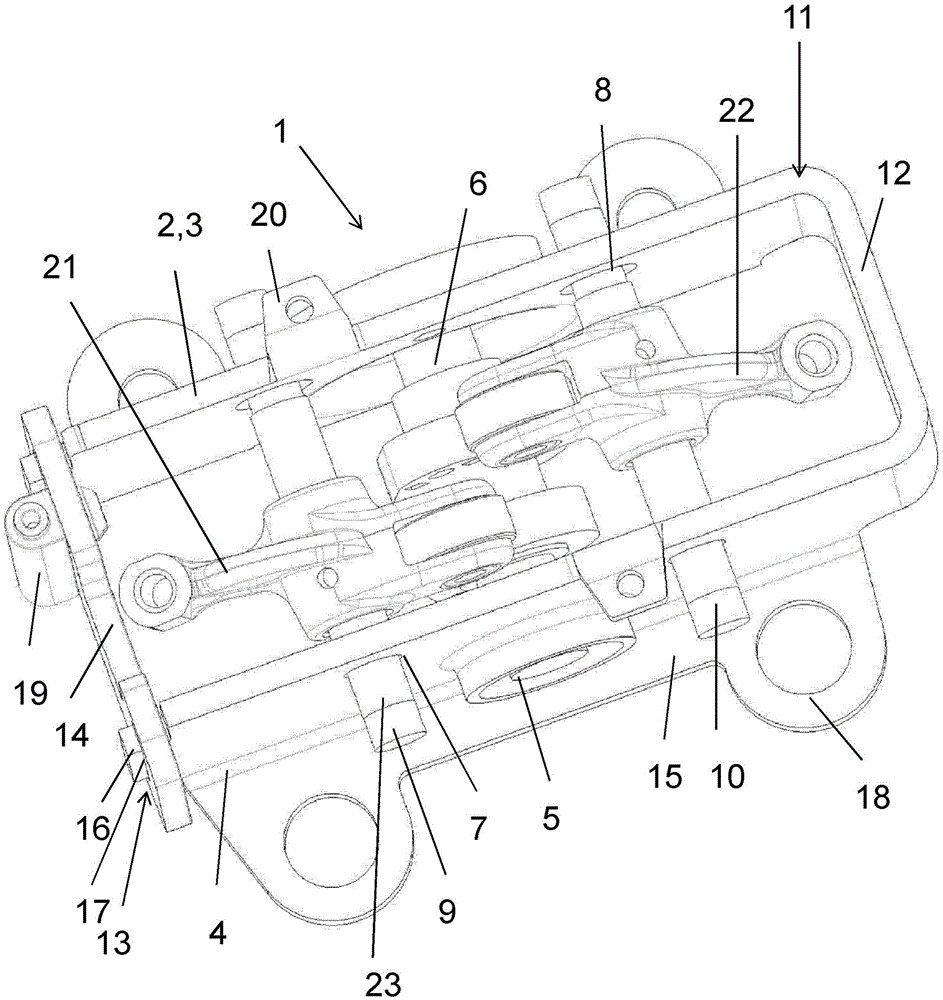

[0014] Shown is a lightweight support module 1 made of steel sheet metal using stamping and bending technology for an OHC valve train of a single-cylinder motorcycle internal combustion engine.

[0015] The carrier module 1 has two upright carrier walls 2 spaced apart from each other. The carrier wall can be connected at its upper end 3 to the cylinder head via one-piece bent tongues 20 (one tongue 20 on each side). The carrier wall 2 has at its lower end 4 a foot 15 bent from the carrier wall with bore holes 18 (two on each side) through which the carrier module 1 can be screwed to the cylinder head of the internal combustion engine. catch.

[0016] As can be seen, each carrier wall 2 has a central main bore 5, in which a camshaft 6 with two lifting cams (1 for intake and 1 for exhaust) is thus accommodated 5 in. The main bore 5 has a rolling or plain bearing (not shown) for carrying the camshaft 6 and is closed on the outside in each case by a cover, which thus protects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com