Heat dissipation hydraulic cylinder

A hydraulic cylinder and cooling fin technology, applied in the field of hydraulic cylinders, can solve problems such as sealing ring aging, heat accumulation, and heat dissipation difficulties, and achieve the effects of simple production and processing, improved service life, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

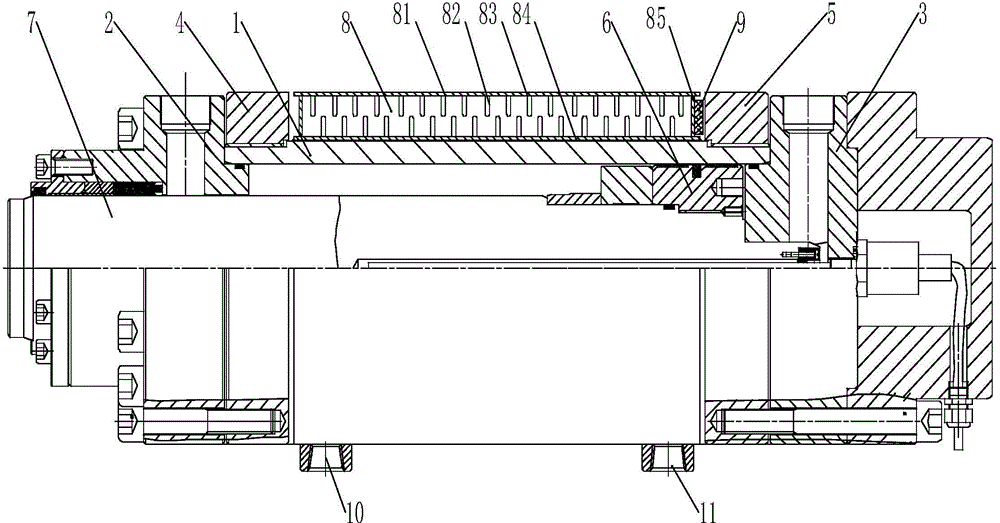

[0015] A heat dissipation hydraulic cylinder, comprising a cylinder body 1, a cylinder head 2, a cylinder bottom 3, a front flange 4, a rear flange 5, a piston 6, and a piston rod 7; the front flange 4 and the rear flange on the outer side of the cylinder body 1 5 are provided with a cooling device 8 and a temperature sensing device 9, the temperature sensing device 9 is arranged on the cooling device 8, the cooling device 8 includes a cooling ring 81 and a cooling fin 82 inside the cooling ring 81, and the cooling ring 81 includes The inner ring 83, the outer ring 84, the side wall 85, the water inlet 10 and the water outlet 11, and the cooling fins 82 are respectively arranged on the inner side of the inner ring 83 and the inner side of the outer ring 84 and arranged in a staggered manner, and the water inlet 10 and the water outlet 11 are arranged on the outer ring 84 outside.

[0016] The temperature sensing device 9 includes a temperature measuring device and a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com