Compact flow guide device and cooling medium storage box

A flow guide device and cooling medium technology, which is applied in the direction of pipes, flange connections, pipes/pipe joints/pipe fittings, etc., can solve the problems of bulky refrigeration devices, separate and independent operation of equipment refrigeration devices, and failure to meet equipment size restrictions, etc. , to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

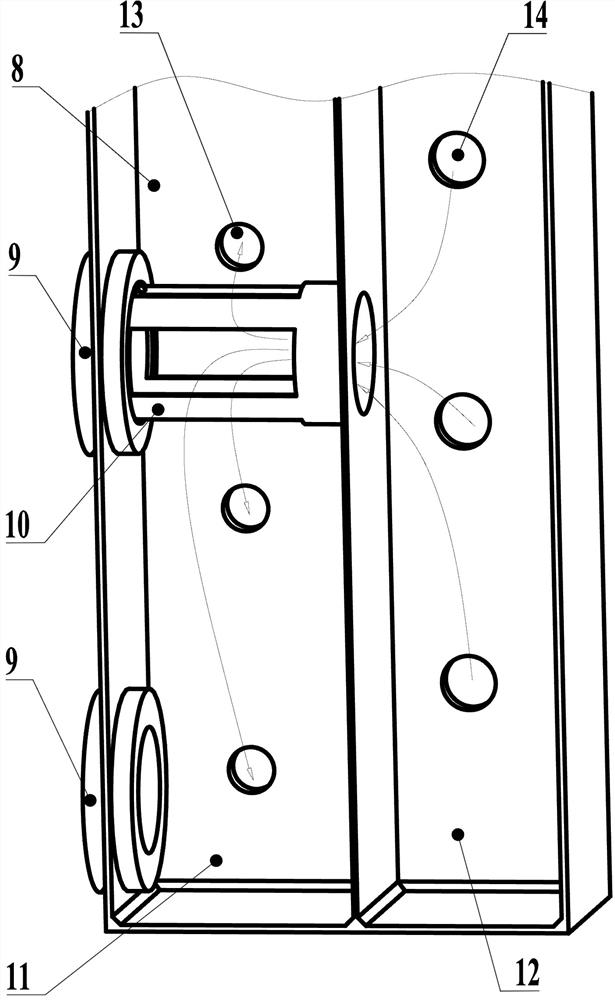

[0014] The present invention is described in further detail as follows in conjunction with the accompanying drawings and embodiments.

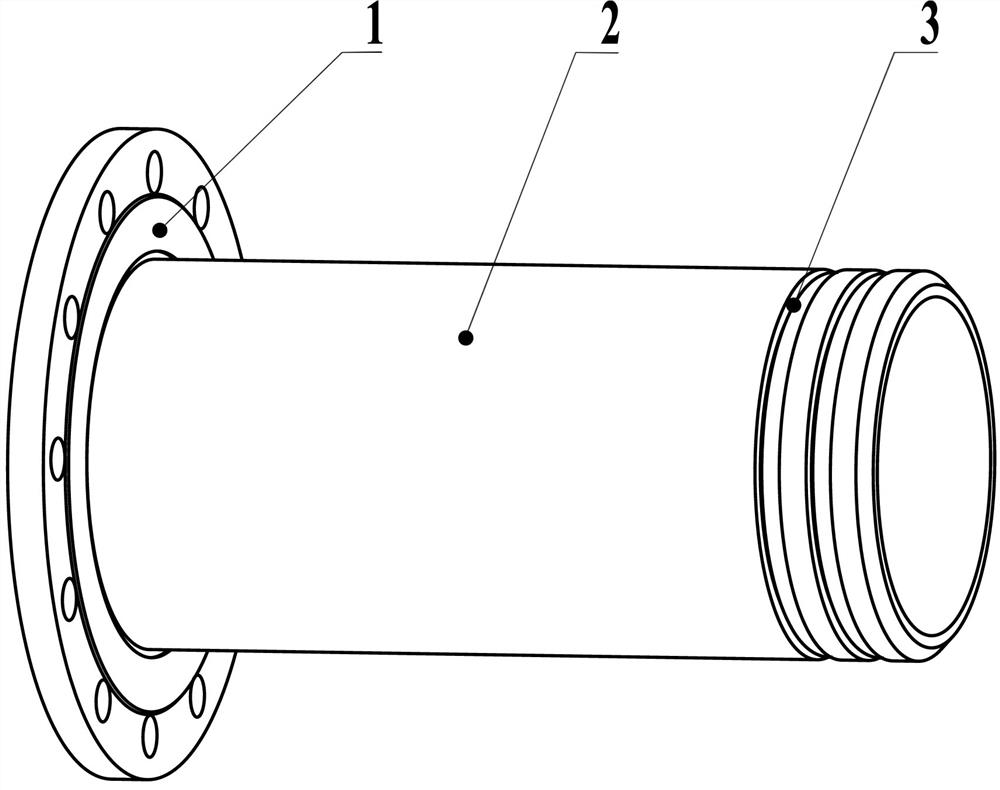

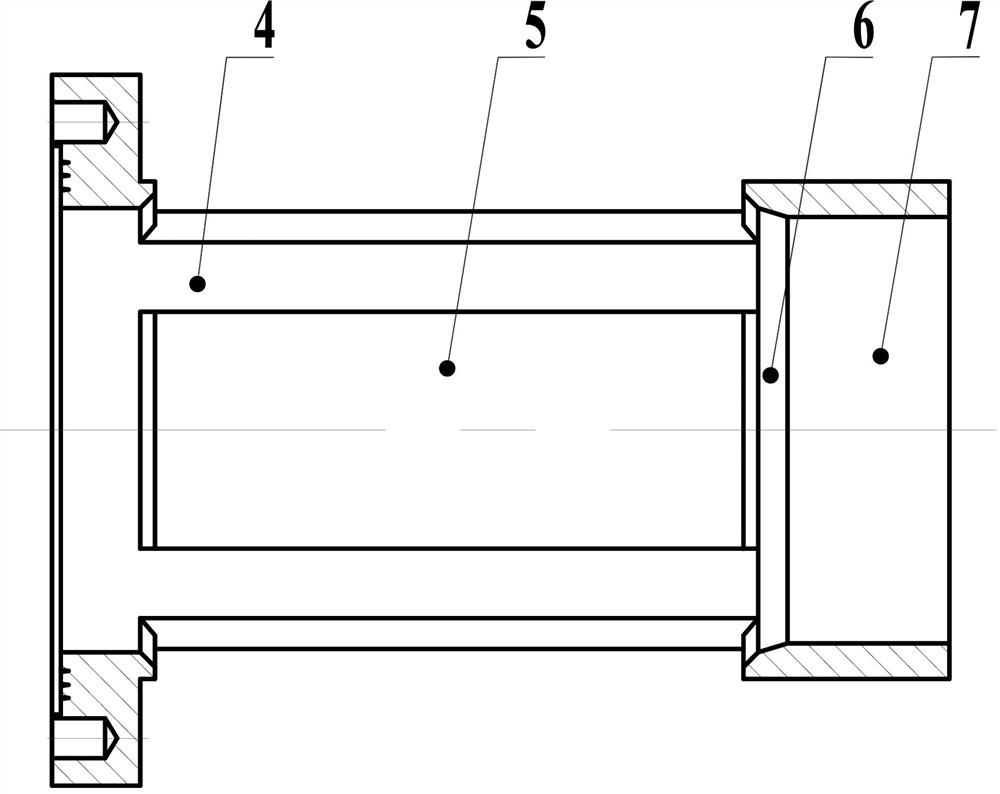

[0015] A compact flow guiding device disclosed by the present invention includes a hollow guide tube 10 and a flange-integrated flow guide tube 2 inserted into the hollow guide tube 10 .

[0016] refer to figure 1 As shown, the flange integrated guide pipe 2 is composed of a flange and a pipe body, a gasket 1 is installed on the flange, and a hole is opened in the center of the flange, which is the same as the inner diameter of the pipe for cooling medium to pass through. , the flange has a hole and a sealing surface for penetrating bolt fastening, which can cooperate with the gasket 1 to realize sealing through the axial compression of the bolt, and the flange surface can use the gasket 1 to realize the axial sealing of the end face. N O-rings 3 are installed on the tail of the body through N annular grooves, and the pipe body and the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com