Measurement system and measurement method for jet noise of water filling pipe

A technology of measurement system and water pipeline, applied to vibration measurement in fluid, measurement vibration, measurement device and other directions, can solve the problems of small jet noise level, submersion, unfavorable underwater jet noise test research, etc., to reduce background noise , the effect of easy test implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] The object of the present invention is to provide a measurement system and method for jet noise of water-filled pipelines, which can solve the measurement problem of jet-flow noise of water-filled pipelines.

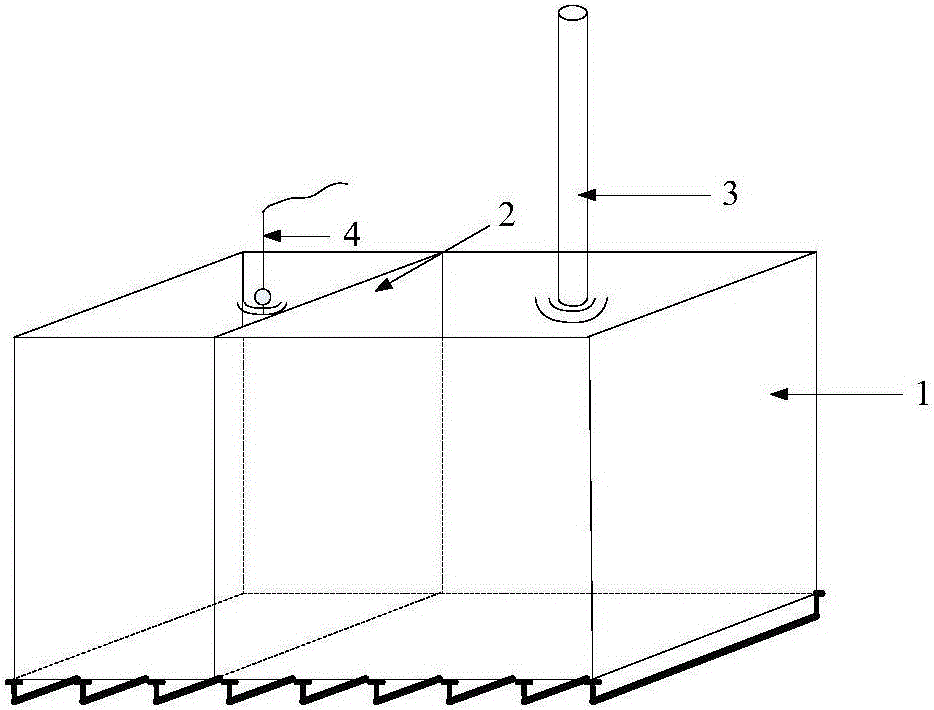

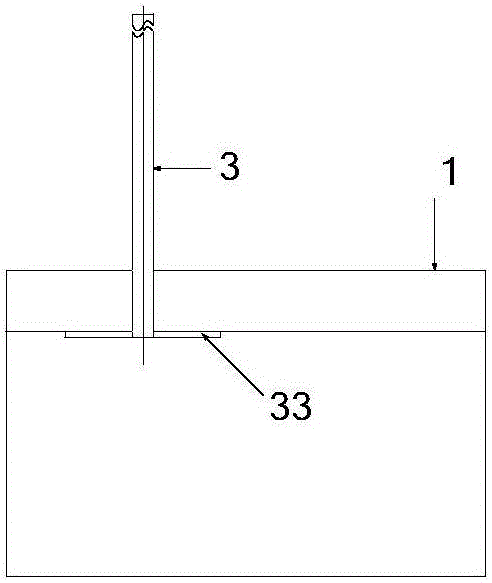

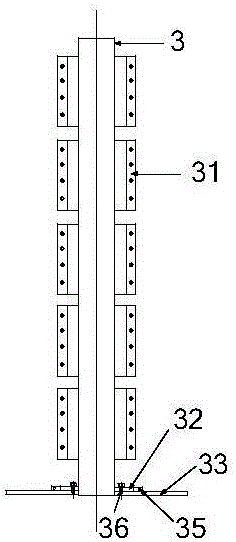

[0031] A measurement system and method for measuring jet noise of a water-filled pipeline, comprising a water-filled pipeline, a reverberation box, a plexiglass plate, and a vertical line array of hydrophones, the water-filled pipeline is installed in the jet flow area in the reverberation box, and the The reverberation box is a cuboid structure without a top cover, the bottom is supported by beams, the inside is filled with water, and the outside is air. The plexiglass plate divides the reverberation box into two parts: a jet area and a test area; the hydrophone The vertical line array is placed in the test area of the reverberation box to col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com