Optical fiber Fabry-Perot ultrasound hydrophone and system

A technology of hydrophone and optical fiber, which is applied in the field of optical fiber Fabry-Perot ultrasonic hydrophone and system, which can solve the problems of difficult sound pressure distribution in HIFU sound field, complex measurement system, and huge data volume. , to achieve the effect of unique practical value, high sound pressure sensitivity and high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

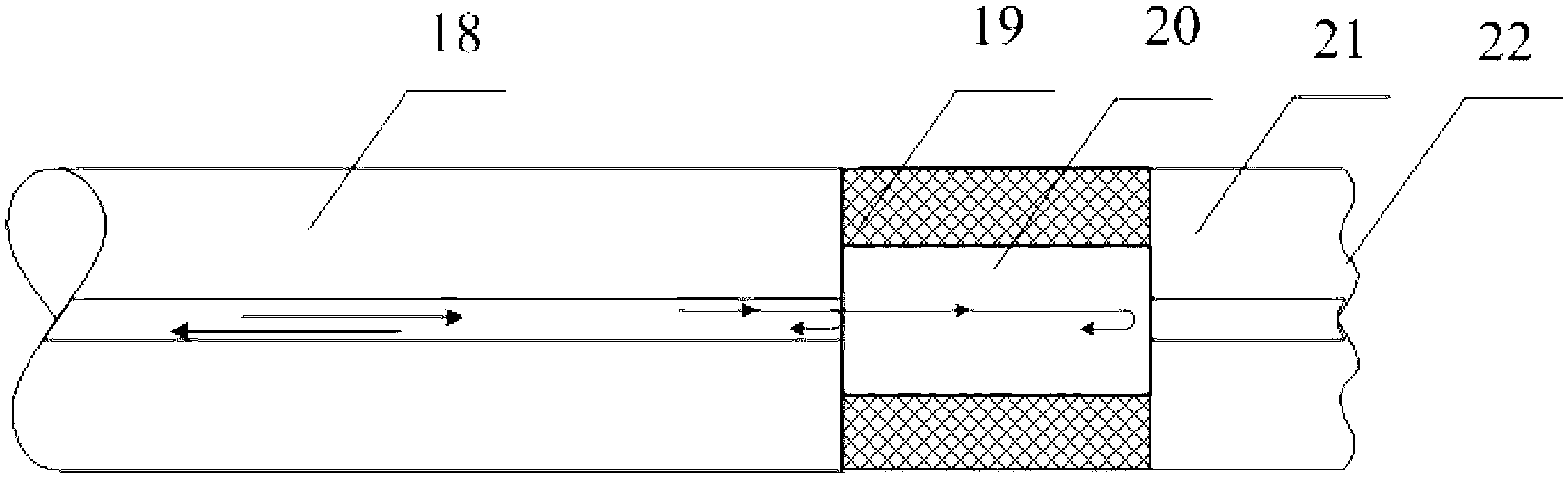

[0034] Please refer to figure 1 , is a structural schematic diagram of the first embodiment of the fiber optic Fabry-Perot ultrasonic hydrophone provided by the present invention. The optical fiber Fabry-Perot ultrasonic hydrophone includes: a single-mode optical fiber 18 , a quartz capillary 19 and a reflection optical fiber 21 . Wherein, the single-mode optical fiber 18 can be an ordinary single-mode bare optical fiber, as shown in the figure. The two ends of the quartz capillary 19 are respectively connected with one end of the single-mode optical fiber 18 and one end of the reflective optical fiber 21 by means of fusion splicing, etc., and the other end of the reflective optical fiber 21, that is, relative to the end connected with the quartz capillary 19, is roughened to reduce The reflectivity of the end face 22 is low to avoid forming multiple Fabry-Perot interference cavities; or, the other end of the reflective fiber 21 is first cut flat and then coated. The air cav...

Embodiment 2

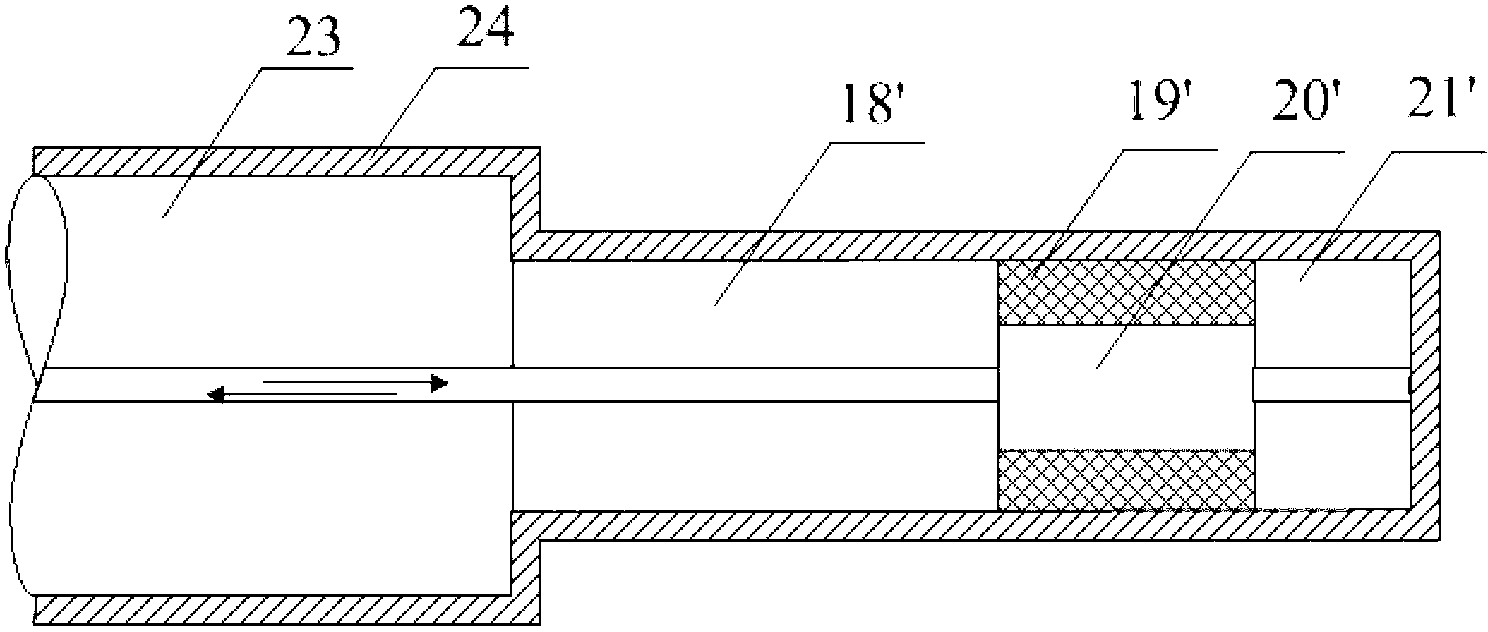

[0036] Please refer to figure 2 , is a schematic structural view of the second embodiment of the fiber optic Fabry-Perot ultrasonic hydrophone provided by the present invention. figure 2 and figure 1 The difference mainly lies in: coating protective film 24 around the coating layer 23 of single-mode optical fiber 18 ′ and reflective optical fiber 21 ′ at a distance from the single-mode optical fiber 18 ′, quartz capillary 19 ′, or armored , to increase the strength of fiber optic Fabry-Perot ultrasonic hydrophones.

Embodiment 3

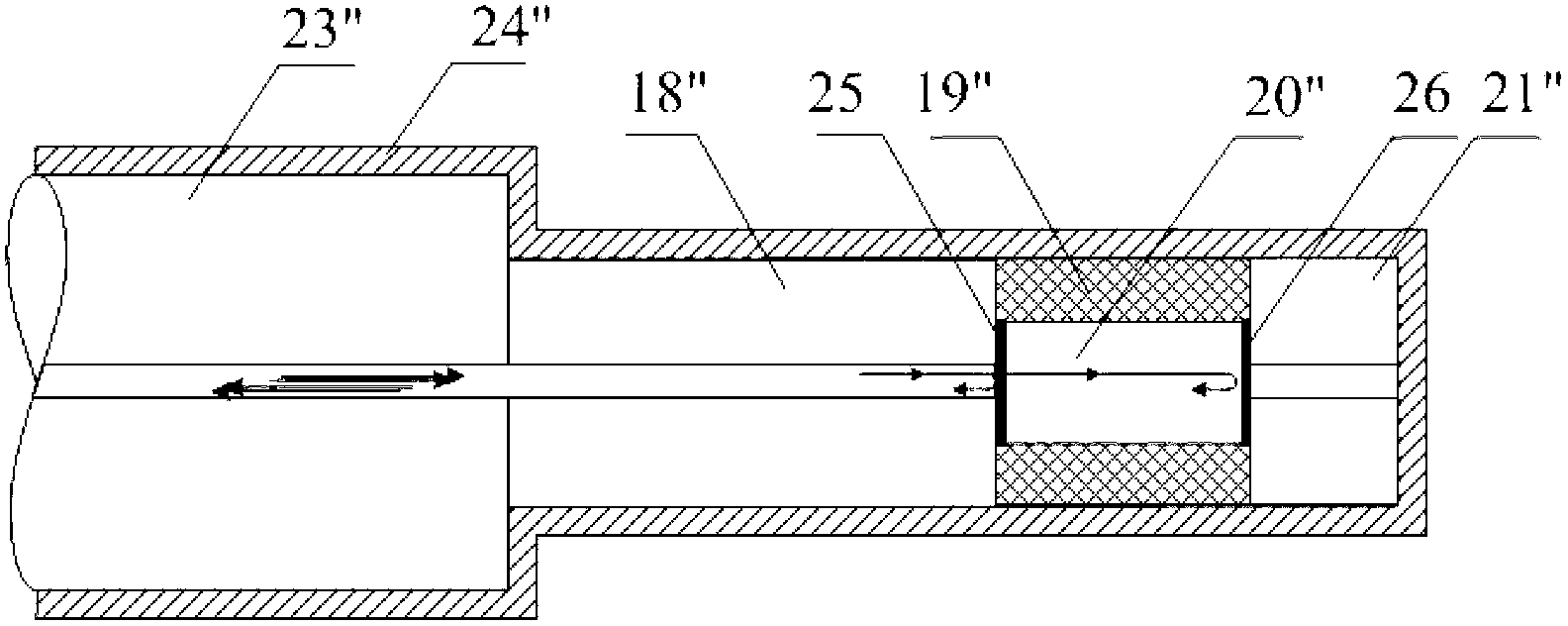

[0038] Please refer to image 3 , is a schematic structural view of the third embodiment of the optical fiber Fabry-Perot ultrasonic hydrophone provided by the present invention. image 3 and figure 1 The main difference is: in the air cavity 20 "a reflective surface is coated with a semi-reflective film 25, and the opposite reflective surface is coated with a reflective film 26 to improve sensitivity. In the single-mode optical fiber 18", the coating layer 23 ", the quartz capillary 19 "and reflective optical fiber 21" around coating protective film 24 "or armoring, to improve intensity.

[0039] The second part: about three embodiments of the optical fiber Fabry-Perot ultrasonic hydrophone system. The fiber optic Fabry-Perot ultrasonic hydrophone system uses Figure 1-3The optical fiber Fabry-Perot ultrasonic hydrophone of the embodiment is therefore very suitable for the measurement of the HIFU sound field, and the following optical fiber Fabry-Perot ultrasonic hydrophon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com