A sensor insulation adaptation structure

A technology for adapting structures and sensors, applied in instruments, scientific instruments, thermometers using electrical/magnetic components that are directly sensitive to heat, etc. Insulation performance, reasonable structure, and the effect of avoiding poor contact problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

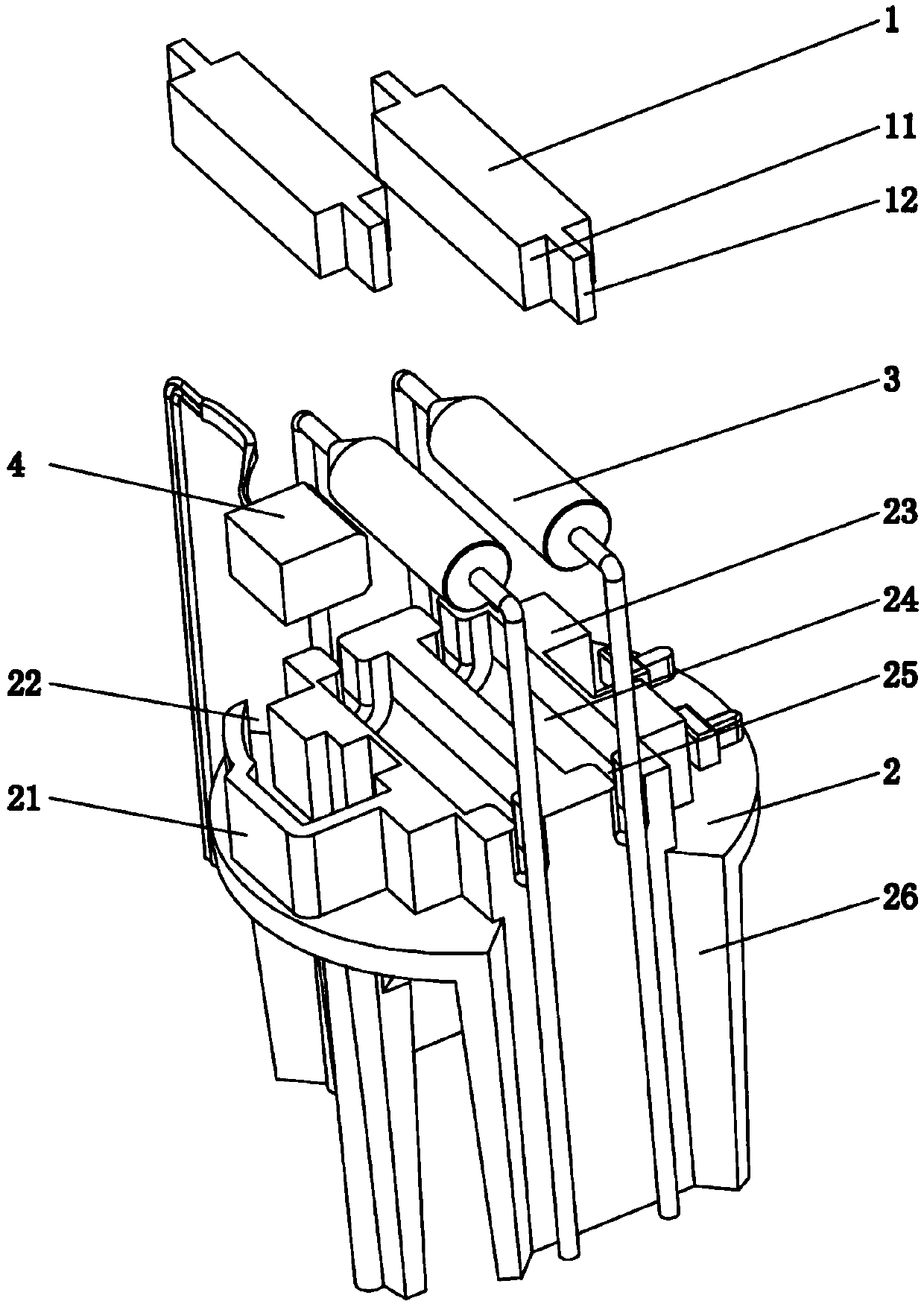

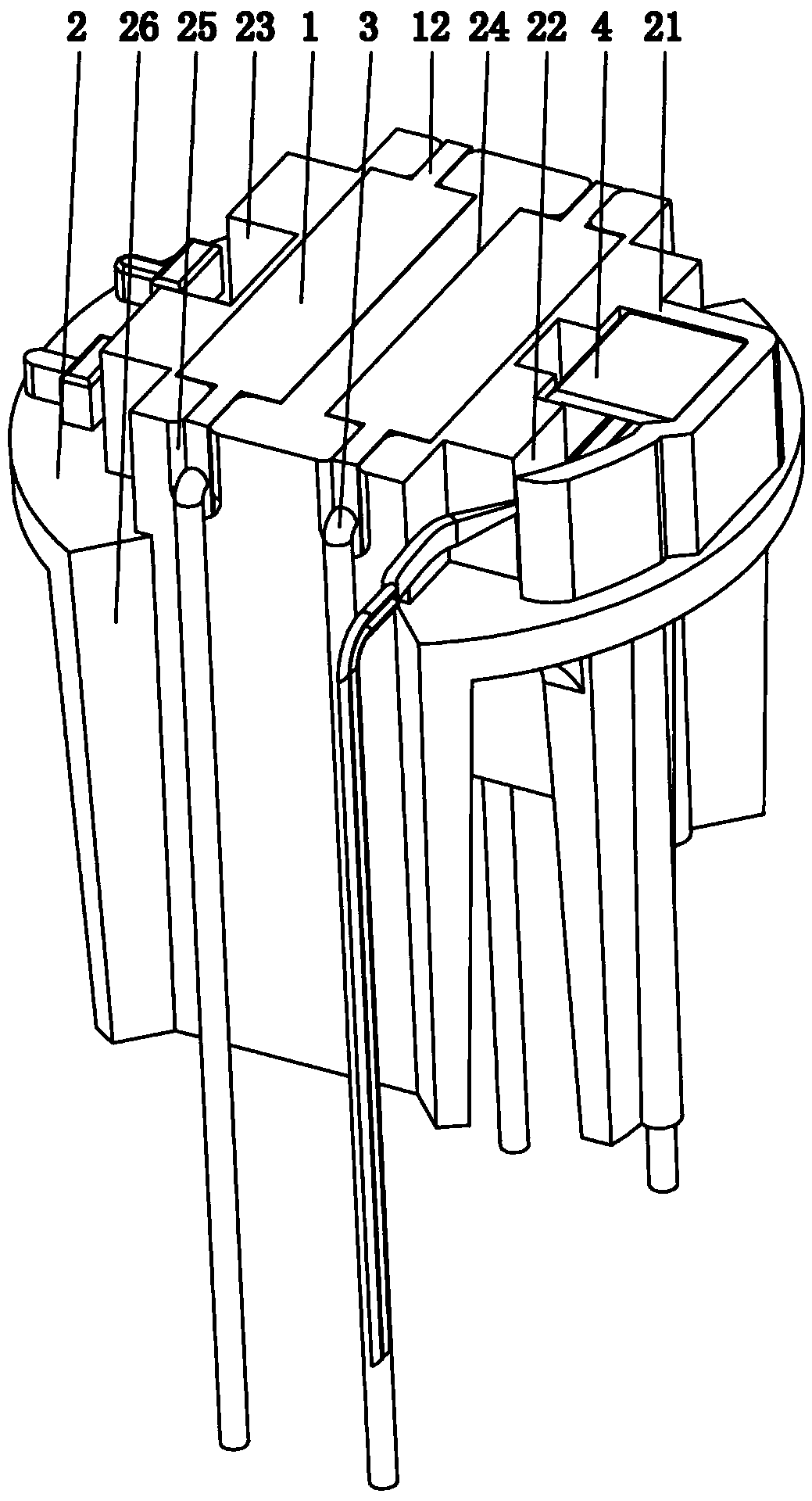

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0022] like figure 1 As shown, a sensor insulation adaptation structure according to the present invention includes a plastic bracket 2 and a thermal fuse 3. A retention frame 23 is arranged on the upper end surface of the plastic bracket 2, and a suitable The limit groove 24 of the thermal fuse 3 is provided, and the thermal fuse 3 is horizontally placed in the limit groove 24; the side walls of the retaining frame 23 at both ends of the limit groove 24 are provided with clamping openings 25, and the thermal fuse 3. The pins at both ends are respectively drawn out horizontally from the corresponding clamping port 25; the limiting groove 24 is provided with an insulating rubber sleeve 1 with a vertical section in an inverted "U" shape, and the insulating rubber sleeve 1 is covered on the thermal fuse 3 On the outer edge of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com