Method and device for measuring temperature in boiler furnace

A boiler furnace and temperature measurement device technology, applied in the field of temperature measurement, can solve the problems of low cost-effective installation, difficult measurement of furnace center temperature, and difficulty in three-dimensional temperature field reconstruction, achieving low cost, saving installation and subsequent maintenance, and realizing The effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

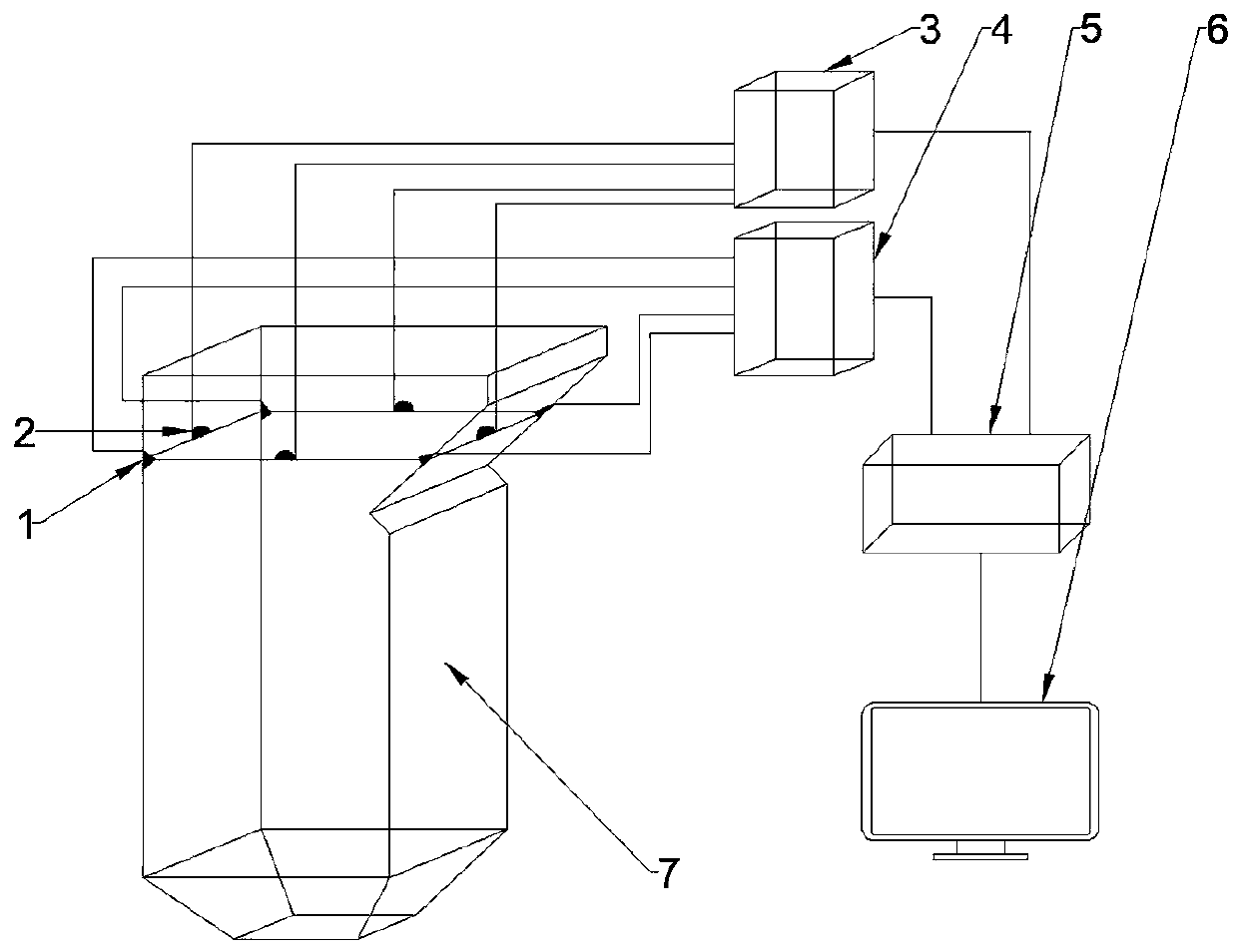

[0044] Such as figure 1 The shown boiler furnace temperature measuring device includes infrared temperature measuring devices 1 fixed at four furnace wall corners on the same horizontal plane of the boiler furnace 7, and acoustic temperature measuring devices are respectively fixed in the middle of two adjacent infrared temperature measuring devices 1 2. The infrared temperature measuring device 1 and the acoustic temperature measuring device 2 are respectively connected to the photoelectric conversion device 4 and the acoustic-electric conversion device 3, and the described photoelectric conversion device 4 and the acoustic-electric conversion device 3 are respectively connected to a signal coupling device 5, The signal coupling device 5 is connected to a display output device 6 .

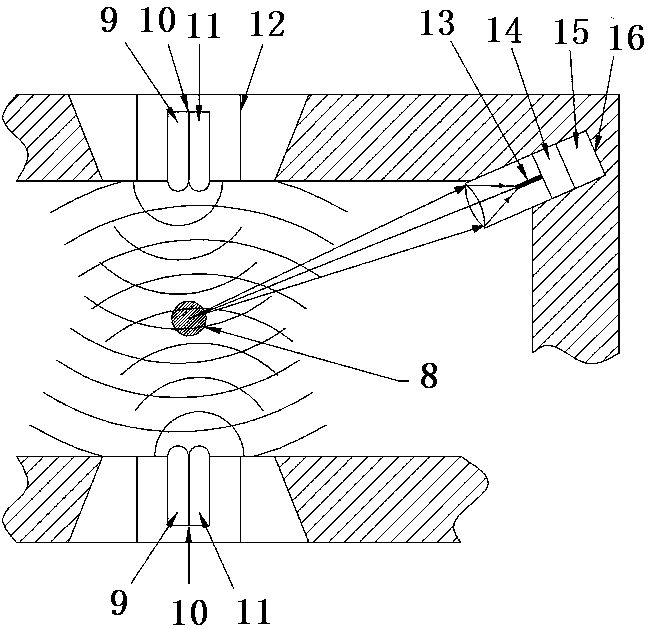

[0045] The principle of infrared and acoustic device temperature measurement is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com