Auxiliary device for tension test of three rows of roller chains

An auxiliary device, tensile test technology, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems affecting test accuracy, test data errors, etc., to improve test work efficiency, structure Reasonable and avoid the effect of trial failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

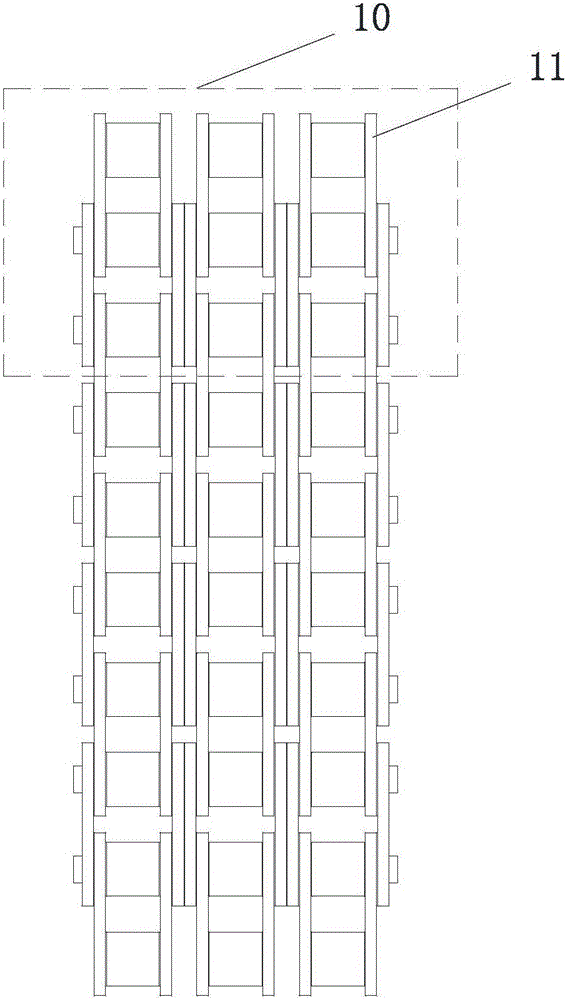

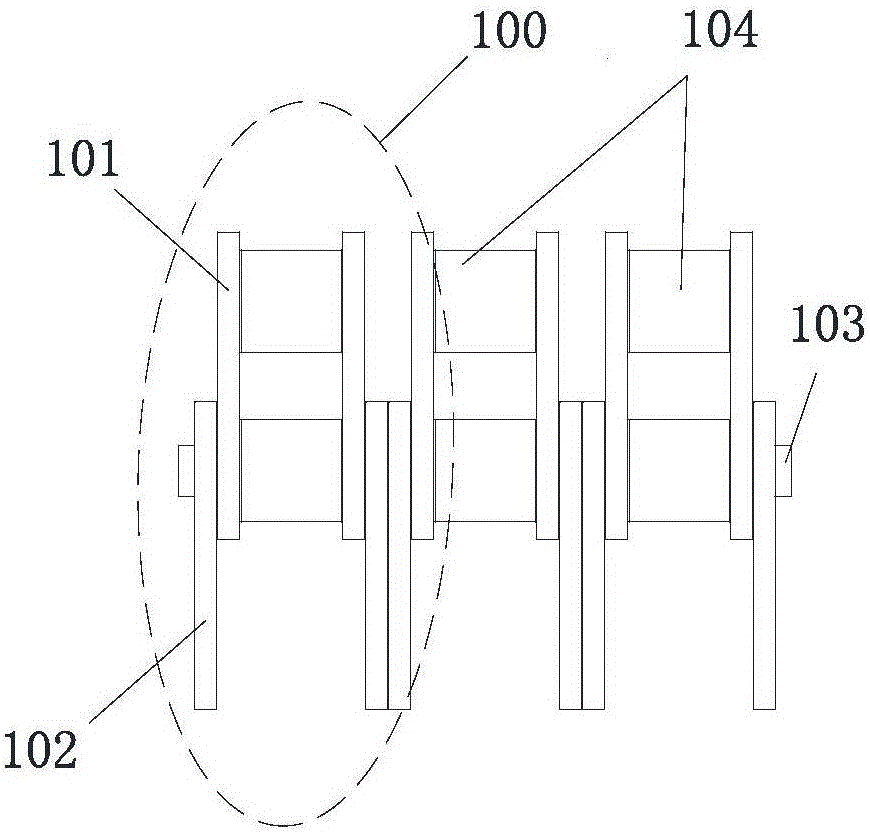

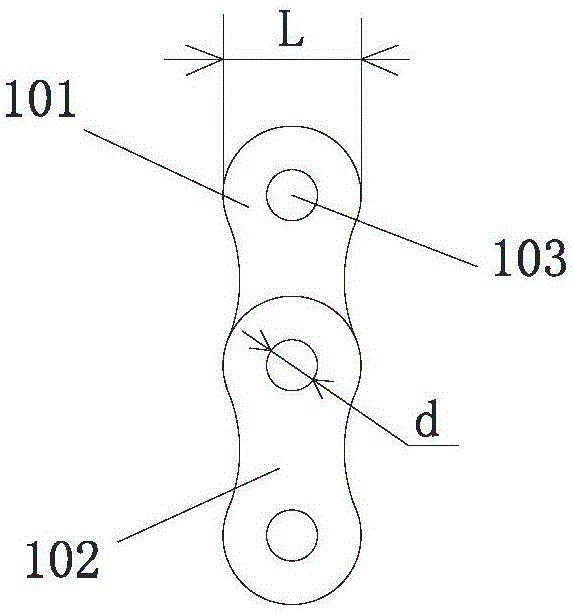

[0032] Image 6 , Figure 7 , Figure 8 An auxiliary device 20 for tensile testing of a three-row roller chain is shown, Figure 4 , Figure 5 It shows the auxiliary device of the tensile test and the assembly diagram of the three-row roller chain sample. The three-row roller chain sample contains several three-row roller chain unit sections 10, and the two ends of which are inner chain plate ends 11. The auxiliary device 20 is used to connect the inner chain plate ends 11 at both ends of the three-row roller chain. The auxiliary device 20 includes a coupling part 21 and a clamping part 22. The clamping part 22 can match the clamping part Hold on the hydraulic chuck of the testing machine, the front end of the coupling part 21 is provided with three coupling square holes 211 side by side, and is provided with a coupling pin shaft through hole 212 passing through the three coupling square holes 211, The diameter d of the pin shaft 103 of the described connecting pin shaft t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com