Application of Mass Spectrometer in Detection of Ionized Intermediates in Catalytic Reaction

A catalytic reaction and mass spectrometry detection technology, applied in the field of catalytic reaction micro-reactors, can solve the problems of limited reaction mechanism research, accurate evaluation of catalytic reaction conditions, limited types of catalytic reaction intermediates, low detection sensitivity and resolution, etc., to achieve rapid Evaluation, scanning speed, high resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

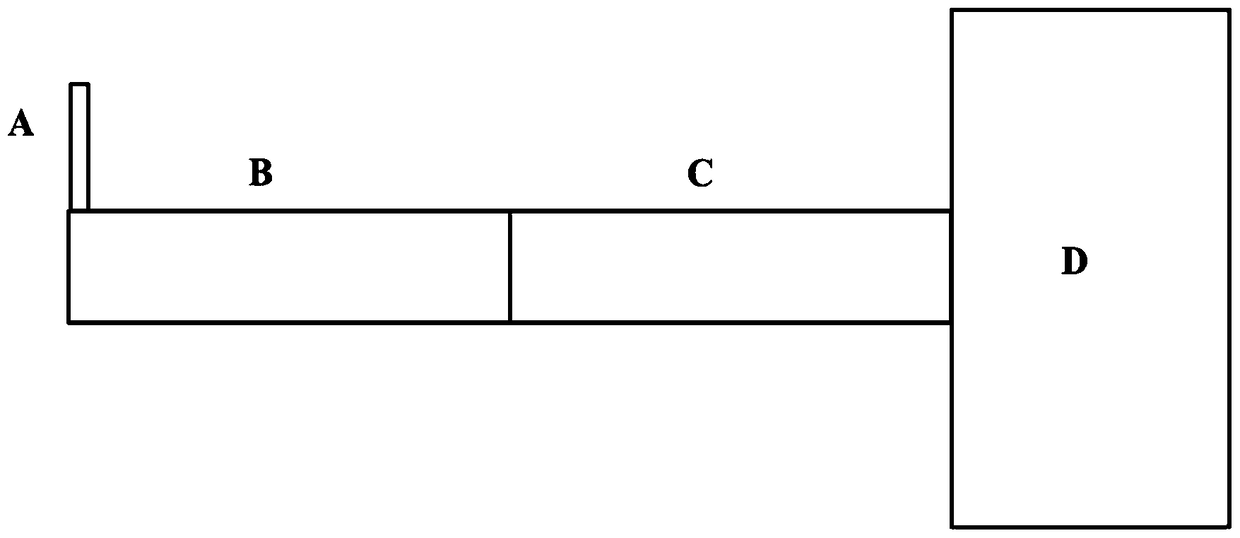

[0032] Such as figure 1 As shown, the catalytic reaction microreactor includes three parts: an inlet, a reaction preparation chamber and a catalytic reaction chamber. The inner diameter and length of the reaction preparation chamber can be designed according to the mass spectrometer model, and the inlet is directly connected to the reaction preparation chamber; The reaction preparation chamber is directly connected to the catalytic reaction chamber, separated by a filter in the middle, and the filter has more than two through holes with a diameter of 0.1-10 microns; the catalytic reaction chamber is directly connected to the entrance of the ion transmission capillary entering the mass spectrometer, and the intermediate passage The filter sheet is separated, and the filter sheet has more than two through holes with a pore size of 0.01-5 microns; the interior of the catalytic reaction chamber is filled with acidic silica-alumina molecular sieves as a reaction catalyst, and the te...

Embodiment 2

[0034] Such as figure 1 As shown, the catalytic reaction micro-reactor includes three parts: an inlet, a reaction preparation chamber and a catalytic reaction chamber. The inner diameter and length of the reaction preparation chamber can be designed according to the mass spectrometer model. In this embodiment, the designed reaction preparation chamber The inner diameter is 0.2mm, the length is 15mm, the diameter of the catalytic reaction chamber is 0.1mm, and the length is 0.8mm. The sample inlet is directly connected to the reaction preparation chamber; With more than 2 through holes with a pore size of 0.1-10 microns; the catalytic reaction chamber is directly connected to the inlet end of the ion transmission capillary entering the mass spectrometer, separated by a filter in the middle, and the filter has more than 2 holes with a pore size of 0.01-5 microns Through holes; the interior of the catalytic reaction chamber is filled with 15 mg of acidic silica-alumina molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com