Vacuum particle counter

A counter and particle technology, which is applied in scientific instruments, individual particle analysis, particle and sedimentation analysis, etc., can solve the problems of no particle counter, no uniform directionality of particles, and difficulty in particle monitoring, so as to increase the effective measurement area. , Increase the probability of particle detection, and expand the effect of collecting solid angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

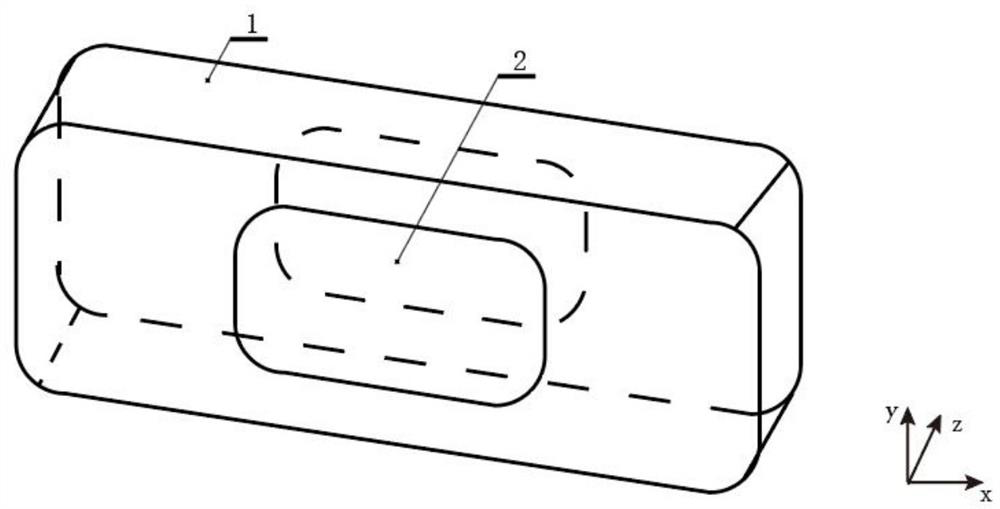

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a vacuum particle counter, including a housing 1, which has a measurement hole 2 passing through the housing 1 along the z direction. The housing 1 can be an aluminum cuboid with a hollow interior, and is blackened to reduce Scattering of light on the inner and outer surfaces of the housing 1, in this embodiment, the x-direction length can be 7 to 12 centimeters, the y-direction width can be 2 to 3.5 centimeters, and the z-direction thickness can be 1.2 to 2 centimeters; the measuring hole 2 can be Set in the middle of the housing 1, it is a long hole, the x-direction length can be set to 3 to 5 cm, and the y-direction width can be set to 1.5 to 3 cm, which can ensure that the particles in the vacuum system to be detected have a sufficient size probability to move into the measurement hole 2, thereby increasing the probability of detecting particles.

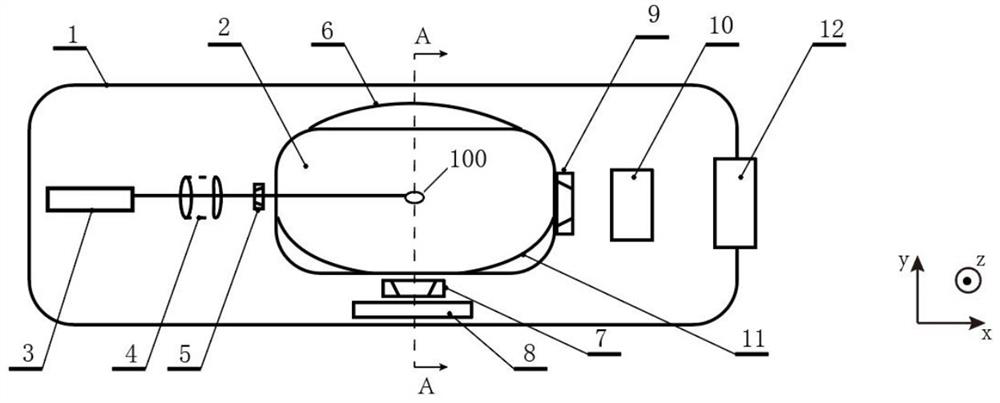

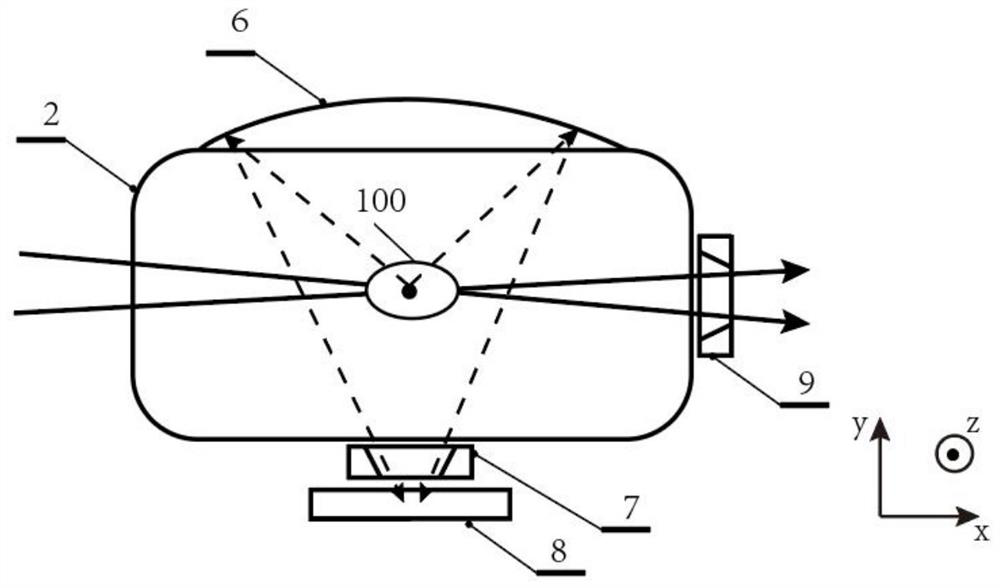

[0037] Such as figure 2 As shown, the in...

Embodiment 2

[0054] This embodiment provides a vacuum particle counter whose structure is basically the same as the vacuum particle counter in the first embodiment, except that the structure of the light detection part in the first embodiment is improved. Such as Figure 12 As shown, the vacuum particle counter of this embodiment includes a housing 1', which has a measuring hole 2' passing through the housing 1' along the z direction. The width of the housing 1' can be set to 3.5 cm and the thickness is 3.5 cm.

[0055]The inside of the housing 1' is sequentially fixed with a light incident part, a light exit part and a light detection part along the x direction, wherein the light incident part is located on the side of the measurement hole 2' in the x direction, and includes lasers 3' arranged in sequence along the x direction, the incident The structure of the optical element group 4 ′ and the entrance diaphragm 5 ′ is the same as that in the first embodiment, and will not be repeated he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com