Wafer processing method

A processing method and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage and attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

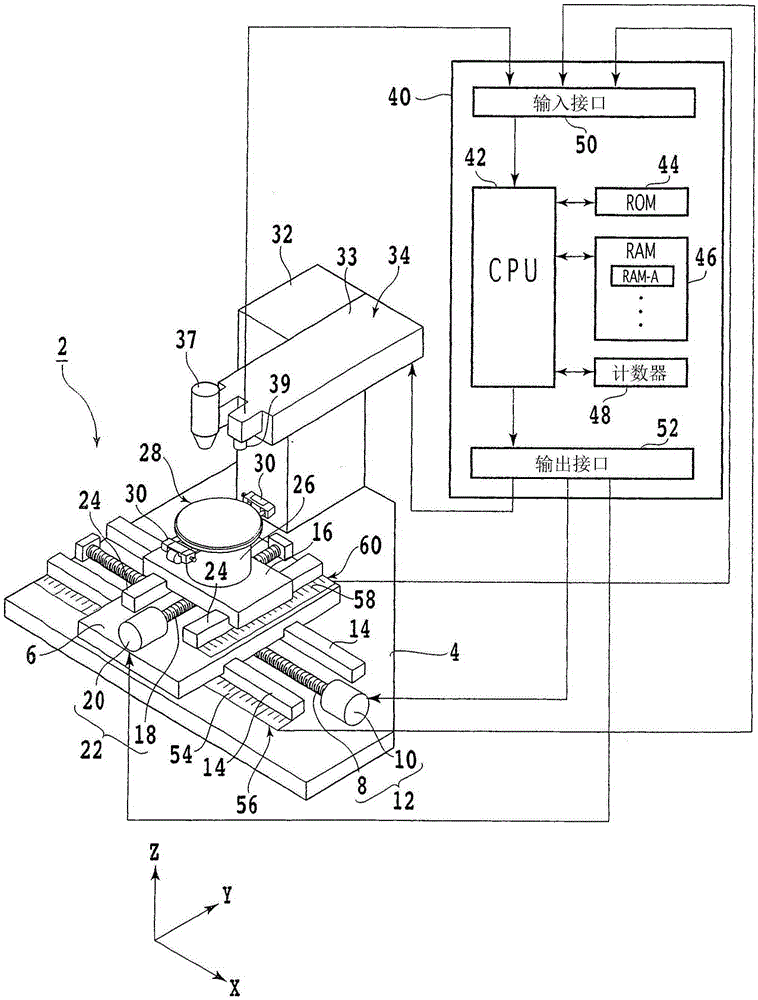

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. when referring to figure 1 , a schematic perspective view of a laser processing apparatus 2 suitable for implementing the wafer processing method of the present invention is shown.

[0032] The laser processing device 2 includes a first slider 6 mounted on a stationary base 4 so as to be movable in the X-axis direction. The first slider 6 moves along a pair of guide rails 14 in the machining feed direction, that is, the X-axis direction, via a machining feed mechanism 12 composed of a ball screw 8 and a pulse motor 10 .

[0033] The second slider 16 is mounted on the first slider 6 so as to be movable in the Y-axis direction. That is, the second slider 16 moves along the pair of guide rails 24 in the index feeding direction, that is, the Y-axis direction, via the index feeding mechanism 22 constituted by the ball screw 18 and the pulse motor 20 .

[0034] On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com