A temperature-stabilized piezoelectric ceramic vibrator

A technology of piezoelectric ceramics and dielectric ceramics, applied in the field of piezoelectric ceramics, can solve problems such as difficulty in mass industrialization, and achieve the effects of improving piezoelectric performance and reliability, improving capacitance-temperature coefficient, and expanding application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

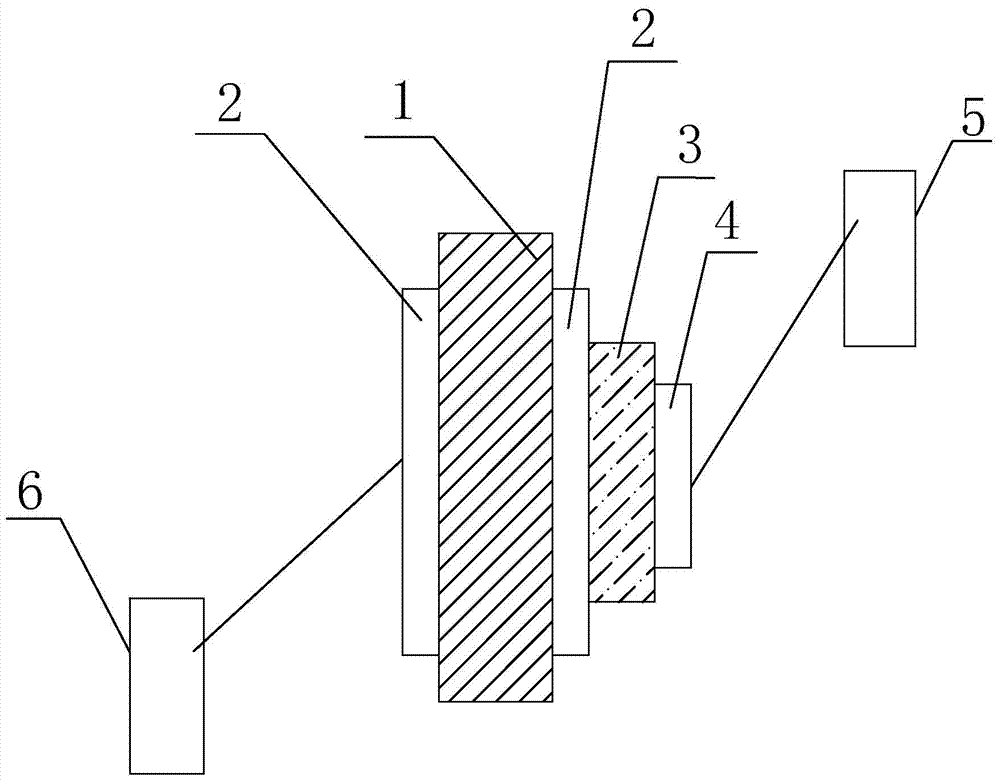

Image

Examples

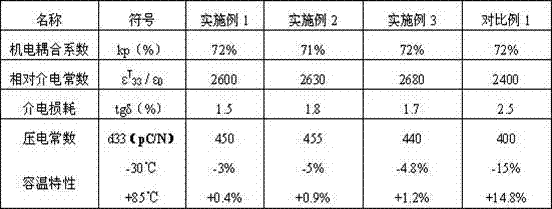

Embodiment 1

[0033]The capacitance temperature change rate of piezoelectric ceramics at -30°C is -14.8%, and the capacitance temperature change rate at +85°C is +12.8%; the capacitance temperature change rate of dielectric ceramics at -30°C is 217%. The capacity temperature change rate at +85°C is -55.2%, the thickness of the dielectric ceramic medium is 20 microns, and the dielectric ceramic medium is fixed on the top or bottom of the piezoelectric ceramic with epoxy resin. Both the piezoelectric ceramic and the dielectric ceramic medium are sintered by the solid-state method to form a multilayer ceramic structure. The first and second electrode layers are silver electrodes with a thickness of 5 microns, and the piezoelectric ceramic vibrator is made as required.

Embodiment 2

[0035] The capacitance temperature change rate of piezoelectric ceramics at -30°C is -15%, and the capacitance temperature change rate at +85°C is +15%; the capacitance temperature change rate of dielectric ceramics at -30°C is 250%. The capacity temperature change rate at +85°C is -60%, the thickness of the dielectric ceramic medium is 40 microns, and the dielectric ceramic medium is fixed on the top or bottom of the piezoelectric ceramic with conductive silver glue. Piezoelectric ceramics and dielectric ceramic media are sintered by solid-state method to form a multilayer ceramic structure. The first and second electrode layers are silver / palladium electrodes with a thickness of 20 microns, and piezoelectric ceramic vibrators are made according to requirements.

Embodiment 3

[0037] The capacitance temperature change rate of piezoelectric ceramics at -30°C is -14.8%, and the capacitance temperature change rate at +85°C is +12.8%; the capacitance temperature change rate of dielectric ceramics at -30°C is 150%. The capacity temperature change rate at +85°C is -30%, the thickness of the dielectric ceramic medium is 60 microns, and the dielectric ceramic medium is fixed on the top or bottom of the piezoelectric ceramic with epoxy resin. Piezoelectric ceramics and dielectric ceramics are sintered by solid-state method to form a multilayer ceramic structure. The first electrode layer is silver / palladium electrode, and the second electrode layer is silver electrode. The thickness is 10 microns. Electric ceramic vibrator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com