Wellhead cable dragging vehicle

A cable and wellhead technology, applied in the field of wellhead cable dragging equipment, can solve the problems of inability to accommodate the traction rope, low work efficiency, complicated installation, etc., and achieve the effects of reducing labor intensity of workers, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

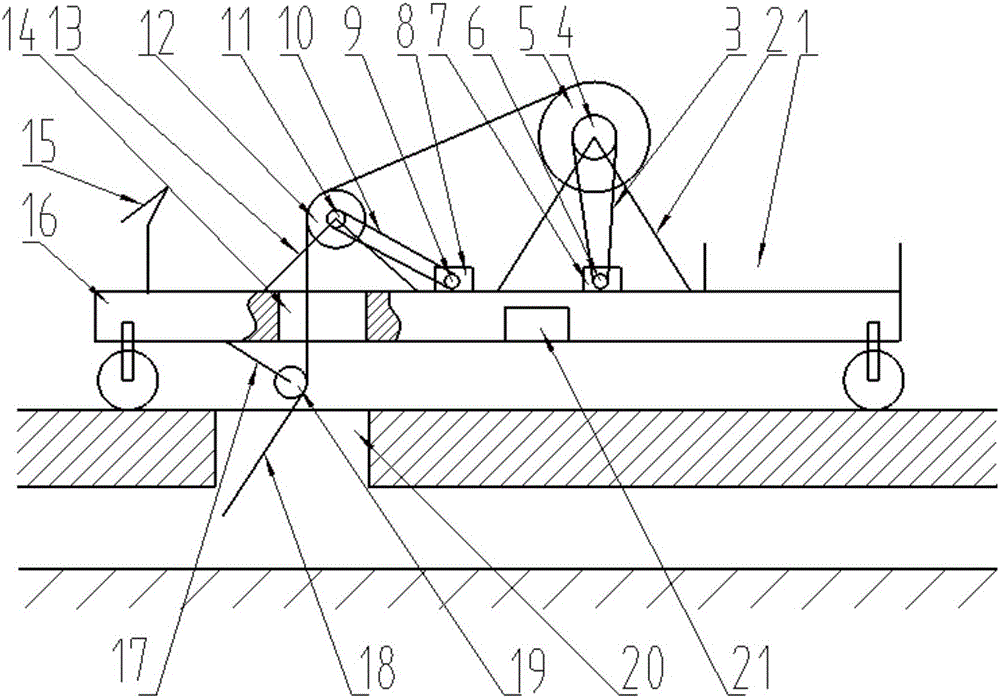

[0019] As per above figure 1 The assembly cost of the shown embodiment is the embodiment of the wellhead cable towing vehicle, including a mobile platform (16), a load area (1), a support A (2), a belt A (3), a pulley B (4), and a storage wheel (5) , Pulley A (6), motor A (7), motor B (8), pulley C (9), belt B (10), pulley D (11), winch (12), bracket B (13), over Line hole (14), console (15), bracket C (17), pulley (19), traction rope (18), battery (21), of which the mobile platform (16) is electrically driven and provided by the battery (21) The power and load area (1) is located on the right side of the mobile platform (16), which is used to carry construction tools, cables and other materials. The bracket A (2) is installed on the mobile platform (16) by screws, and the storage wheel (5) ) Is installed on the bracket A (2), the storage wheel (5) can be rotated by the motor (7) to complete the storage function of the traction rope, the pulley A (6) is installed on the storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com