Purple-series coarse grain compound lactobacillus beverage and preparation method thereof

A compound lactic acid bacteria and a series of technologies are applied in the field of purple series coarse grain compound lactic acid bacteria beverages and their preparation fields to achieve the effects of enhancing intestinal peristalsis and body metabolism, unique flavor and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

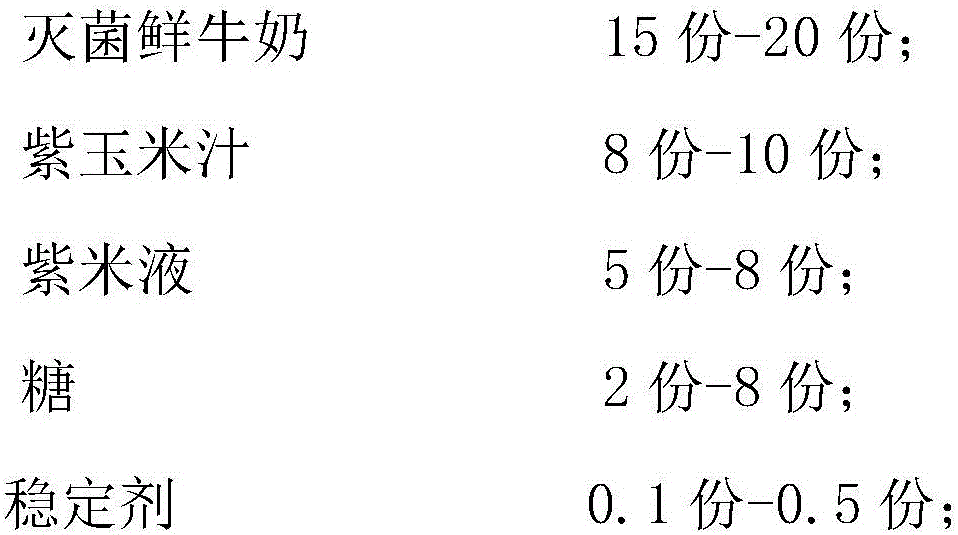

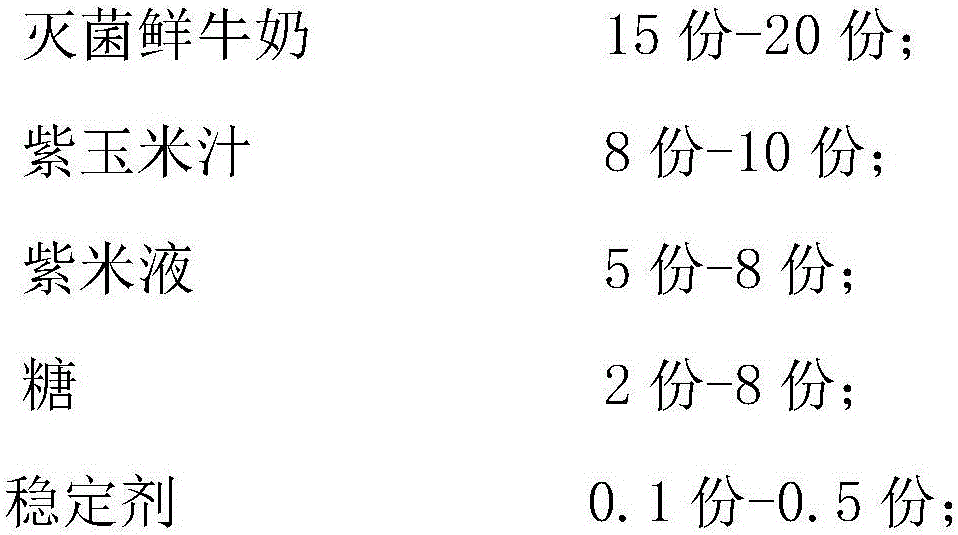

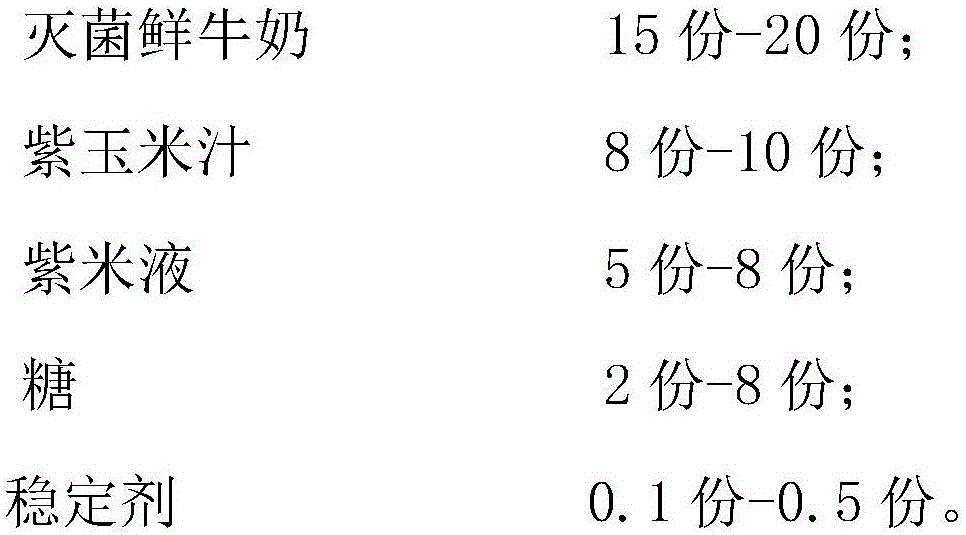

[0031] The preparation method of the purple series coarse grain compound lactic acid bacteria drink in this specific embodiment is divided into five steps: step one: preparation of purple corn juice; step two: preparation of purple rice liquid; step three: preparation of sterilized fresh milk; step four ; Preparation of starter; Step 5: Preparation of purple series coarse grain compound lactic acid bacteria beverage.

[0032] As a preference, the preparation process of purple corn juice in step 1 is as follows: a1. Take fresh, high-quality raw purple corn kernels, clean them with water, and add purple corn kernels to purified water at a ratio of 1:3-1:10. Soak purple corn kernels in pure water for 6-10 hours, pick up and drain, and cook at 100°C for 10-15 minutes;

[0033] a2. Put the cooked purple corn kernels into the beater, beat the cooked purple corn kernels and purified water at a ratio of 1:5, filter the slurry through gauze, centrifuge at 2000-3000r / min for 5-10min, an...

Embodiment 1

[0045] Embodiment 1: Take fresh, high-quality raw purple corn kernels, wash them with clear water, add pure water at a ratio of 1:3 between purple corn kernels and purified water, soak the purple corn kernels for 10 hours, pick up and drain, and cook at 100°C 15min; beat the cooked purple corn kernels and purified water at a ratio of 1:5, filter the slurry through gauze, centrifuge at 3000r / min for 5min, and take the supernatant for later use; take 8 parts by weight of the above supernatant and put it at 90°C Keep the temperature constant in a water bath, adjust the pH to 6.2 with citric acid and sodium tripolyphosphate, add 2‰ high-temperature α-amylase of purple corn supernatant, keep the temperature for 15 minutes, raise the temperature to boiling state and keep it for 5 minutes; quickly cool to 62 ℃, adjust the pH to 4.2 with malic acid; add 4‰ glucoamylase of the purple corn supernatant, keep the temperature for 50 minutes, raise the temperature to boiling state and keep i...

Embodiment 2

[0049] Example 2: Take fresh, high-quality raw purple corn kernels, wash them with clean water, add pure water at a ratio of 1:8 between purple corn kernels and purified water, soak the purple corn kernels for 6 hours, pick up and drain, and cook at 100°C 10min; beat the cooked purple corn kernels and purified water at a ratio of 1:5, filter the slurry through gauze, centrifuge at 2500r / min for 8min, and take the supernatant for later use; take 10 parts by weight of the above supernatant and put it at 95°C Keep the temperature constant in the water bath, adjust the pH to 6.8 with citric acid and sodium tripolyphosphate, add 2‰ high-temperature α-amylase of purple corn supernatant, keep the temperature for 20 minutes, raise the temperature to boiling state and keep it for 5 minutes; quickly cool to 62 ℃, adjust the pH to 4.5 with malic acid, add 4‰ of the purple corn supernatant glucose starch glucoamylase, keep the temperature for 60 minutes, raise the temperature to boiling st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com