A kind of inner tube and its manufacturing process

一种内胎、内层的技术,应用在其他家里用具、家里用具、中空物品等方向,能够解决控制力变差、拉力不均、易出现漏气等问题,达到减小圆周误差、提高反弹能力、保证稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

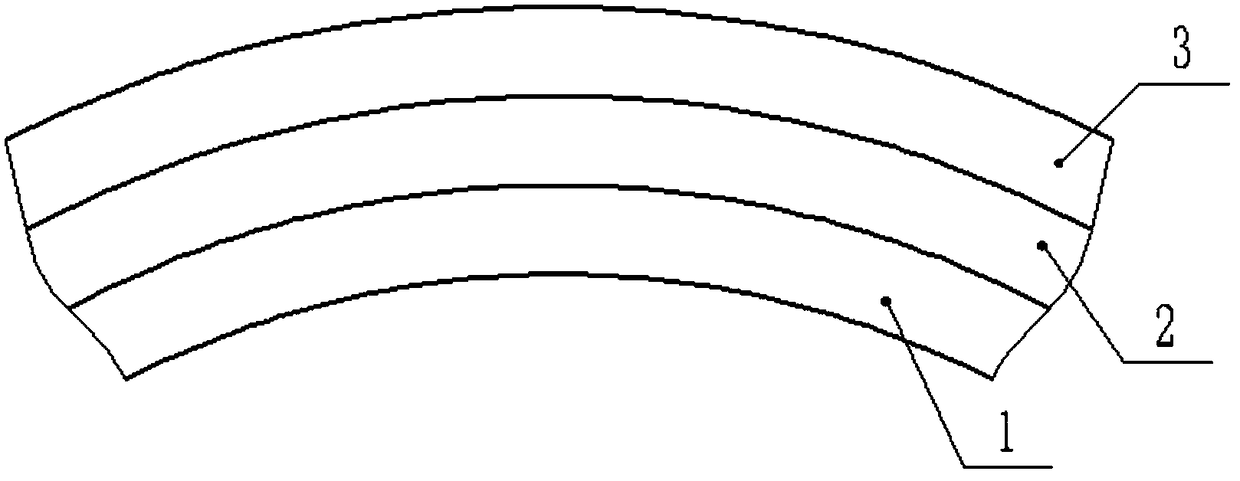

[0034] like figure 1 As shown, a kind of inner tube provided by the present invention comprises an inner tube body 1, a yarn layer 2 and a rubber layer 3, and the yarn layer 2 is attached to the outer surface of the inner tube body 1; the rubber layer 3 is attached on the outer surface of the yarn layer 2, and then vulcanized so that the rubber raw material of the rubber layer 3 penetrates into the yarn layer 2, and the inner tube body 1, the yarn layer 2 and the rubber layer 3 form one.

Embodiment 2

[0036] In order to prevent the yarn layer 2 from being too thick and wound onto the inner tube body 1, the surface of the prepared inner tube will be hard, which will affect the bouncing force of the ball. The main body 1 is insufficiently bound, resulting in insufficient strength of the inner tube, poor damage resistance, and not durable. In the present invention, preferably, the thickness of the yarn layer is 0.1-1 mm. The thickness of the yarn layer 2 ensures that the inner tube body 1 is sufficiently restrained to improve the inner tube strength while taking into account the surface hardness of the ball to ensure the bouncing force of the ball.

Embodiment 3

[0038] In order to ensure the balance and flight stability of the ball, when the player hits the ball, the deviation between the actual flight trajectory of the ball and the ideal flight trajectory is small, thereby improving the hitting rate of the ball. The inner tube of the present invention is provided with a balance sheet, and the balance sheet is located on the same axis as the air nozzle and symmetrical to the center of the sphere, so as to ensure that the overall center of gravity of the inner tube deviates from the center of the sphere to a minimum. When the inner tube is attached to the upper shell , the weight of the balance piece makes the overall center of gravity of the ball be at the center of the ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com