Interlocking device applied to raw coal slag discharging of coal mill

A technology of interlocking device and coal mill, which is applied in the direction of grain processing, etc., can solve the problems of spontaneous combustion of coal powder and high oxygen content inside the coal mill, and achieve the effects of improving safety, avoiding spontaneous combustion, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

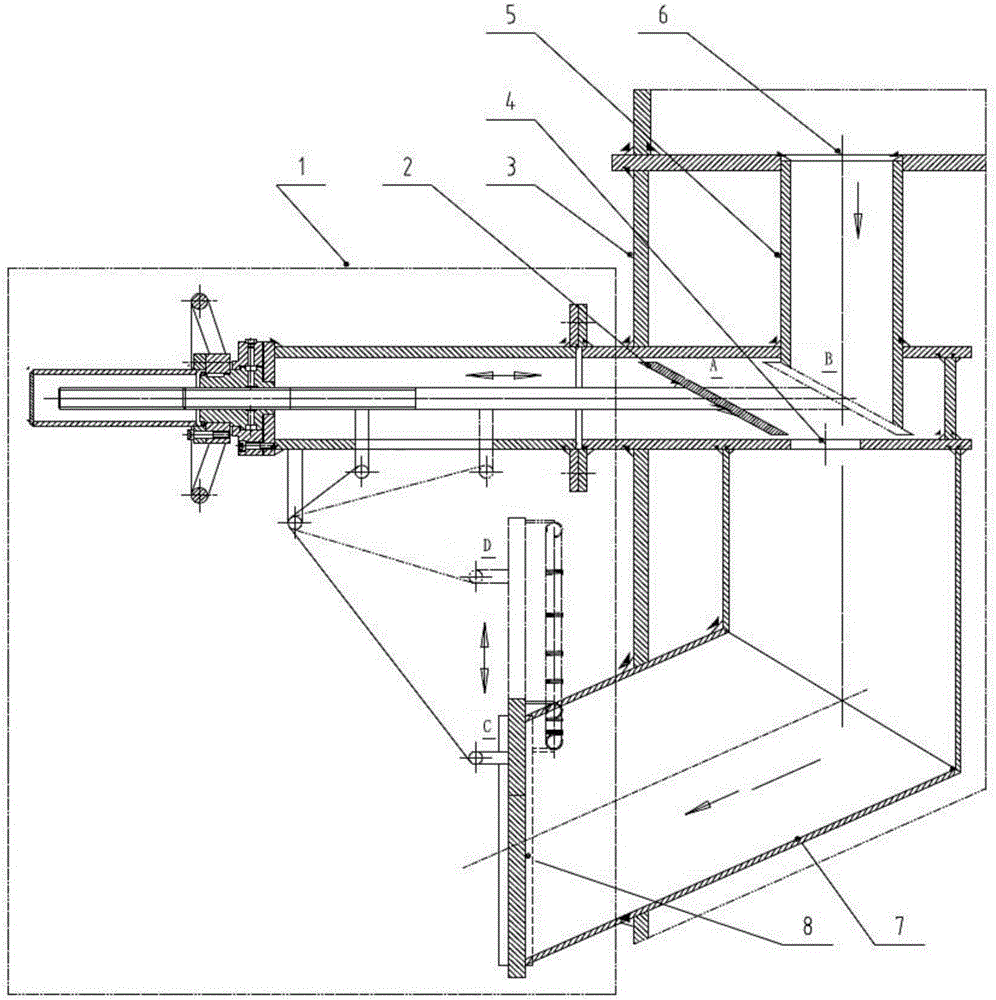

[0020] Such as figure 1 As shown, an interlocking device of the present invention applied to coal mill raw coal slag discharge includes a coal cinder channel 5 and a cinder box 7 arranged inside the coal mill shell 3 . The upper part of the cinder channel 5 is provided with a cinder inlet 6, and the lower part of the cinder channel 5 is provided with a cinder channel opening 4 communicating with the upper part of the cinder box 7, and the cinder channel opening 4 is provided with a cinder channel shutter 2, and the lower part of the cinder box 7 is provided with a cinder box outlet 8 , The main body 1 of the slag discharge device is provided outside the coal mill housing 3 .

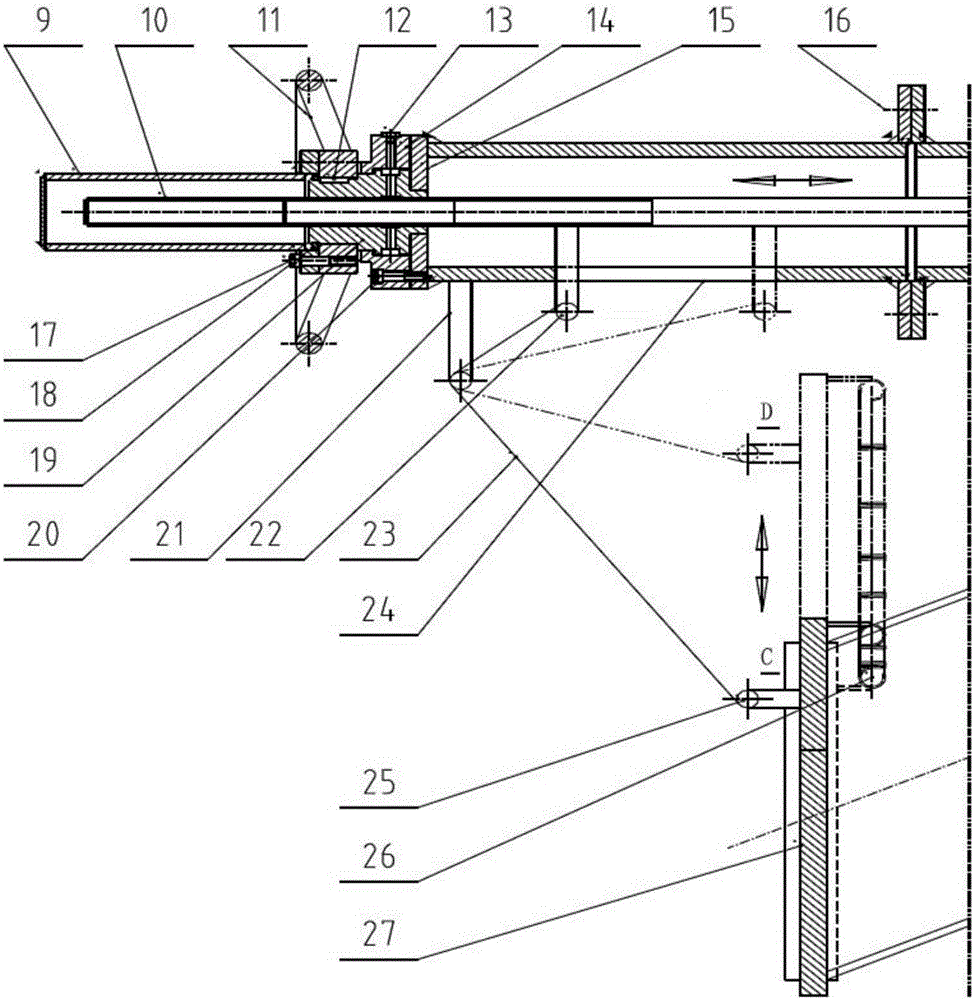

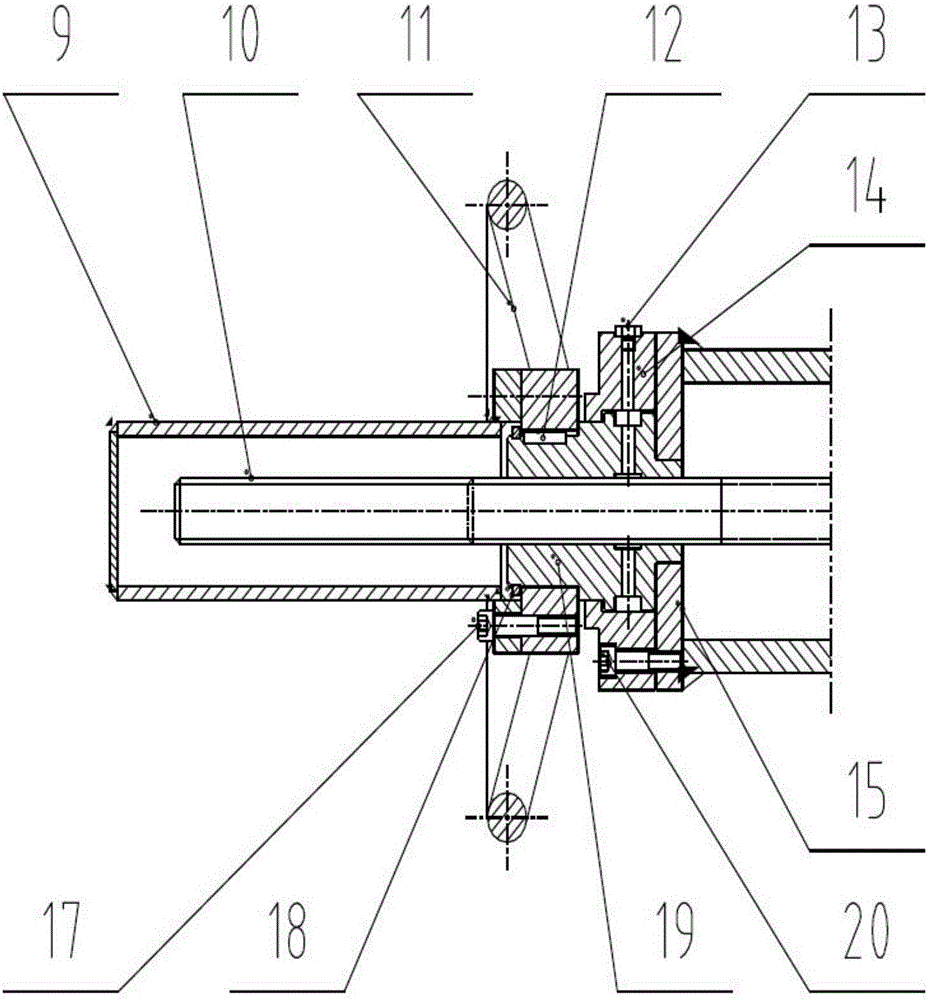

[0021] Such as figure 2 and 3 As shown, the main body 1 of the slag discharge device includes a handwheel drive mechanism, a screw 10 , a support frame 15 , a wire rope sheave block 1 21 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com