A method for adjusting the secondary cooling roll gap in continuous casting of shaped billets

A special-shaped billet continuous casting and adjustment method technology, applied in the field of material forming and control, can solve the problems of large cooling difference, complex, irregular solidification shrinkage, etc., and achieve the effect of ensuring accuracy and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with specific embodiments.

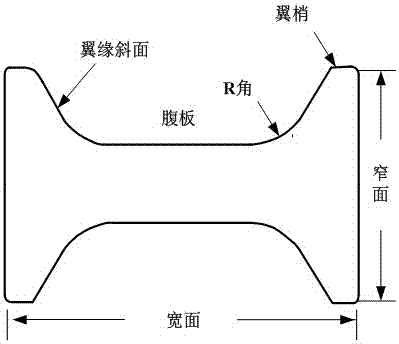

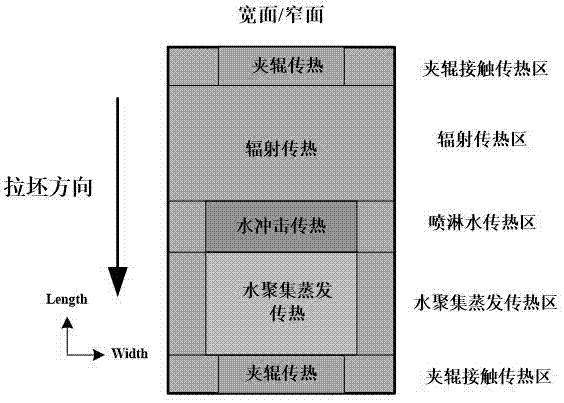

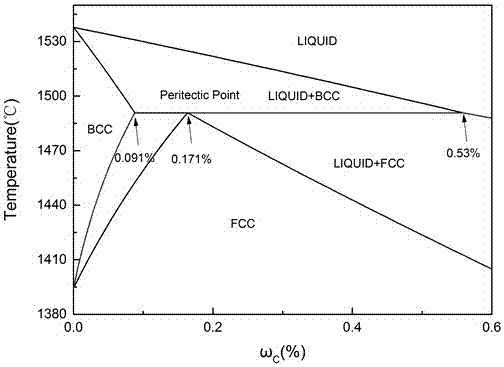

[0063] Roll gap shrinkage is an important process system for continuous casting secondary cooling. Unreasonable roll gap shrinkage will cause large bulging deformation of the billet, and various surface and internal quality problems are prone to occur. The shape of the profiled slab is complex. Compared with the conventional slab, the thickness of the slab shell at each position of the slab section is quite different. During the continuous casting of the profiled slab, the heat dissipation conditions at each position of the slab section are significantly different, and the solidification shrinkage is more complicated. The web, R Surface longitudinal cracks at the corners, web center cracks, and bulging problems occur more frequently. In continuous casting of profiled billets, if the method of slab and square billet is used to determine the shrinkage curve of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com