Clamping support sprue milling and point painting device

A technique of spotting paint and gates, applied in positioning devices, spraying devices, milling machines, etc., can solve problems such as gate traces, and achieve the effect of improving product quality and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

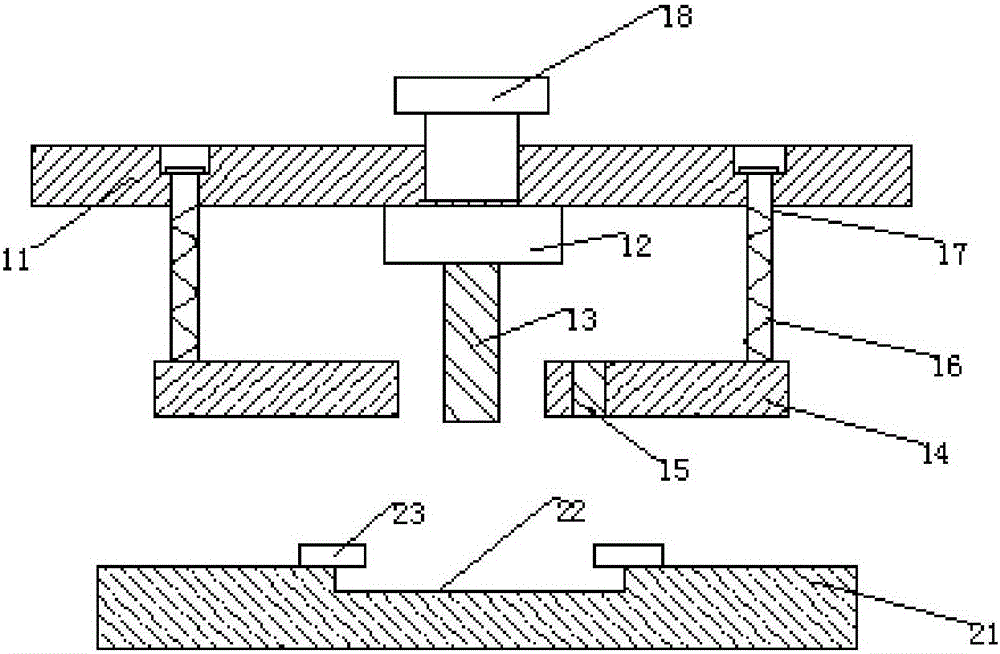

[0019] see figure 1 , a kind of card holder gate milling spot paint device of the present embodiment comprises:

[0020] The upper die set is provided with a driving device 18 for driving the movement of the upper die set. The upper die set includes an upper die set 11, a milling cutter 13, a discharge plate 14 and a discharge nail 17, and the upper die set 11 and the milling cutter An upper backing plate 12 is arranged between the knives 13, a paint spray nozzle 15 is arranged on the unloading plate 14, an elastic member 16 is arranged between the upper mold base 11 and the unloading plate 14, and unloading nails 17 pass through the upper part in sequence from top to bottom. The mold base 11, the elastic member 16 are connected with the stripper plate 14; and

[0021] The lower die set, the lower die set is located below the upper die set, the lower die set includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap