Special clamping device for slidably positioning and pneumatically clamping feed dog to machine top surface

A pneumatic clamping and feeding dog technology, applied in the direction of metal processing equipment, positioning devices, metal processing machinery parts, etc., can solve the problems of increased production cost, low processing accuracy, poor product quality, etc., to reduce waste and improve production Efficiency, fast positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

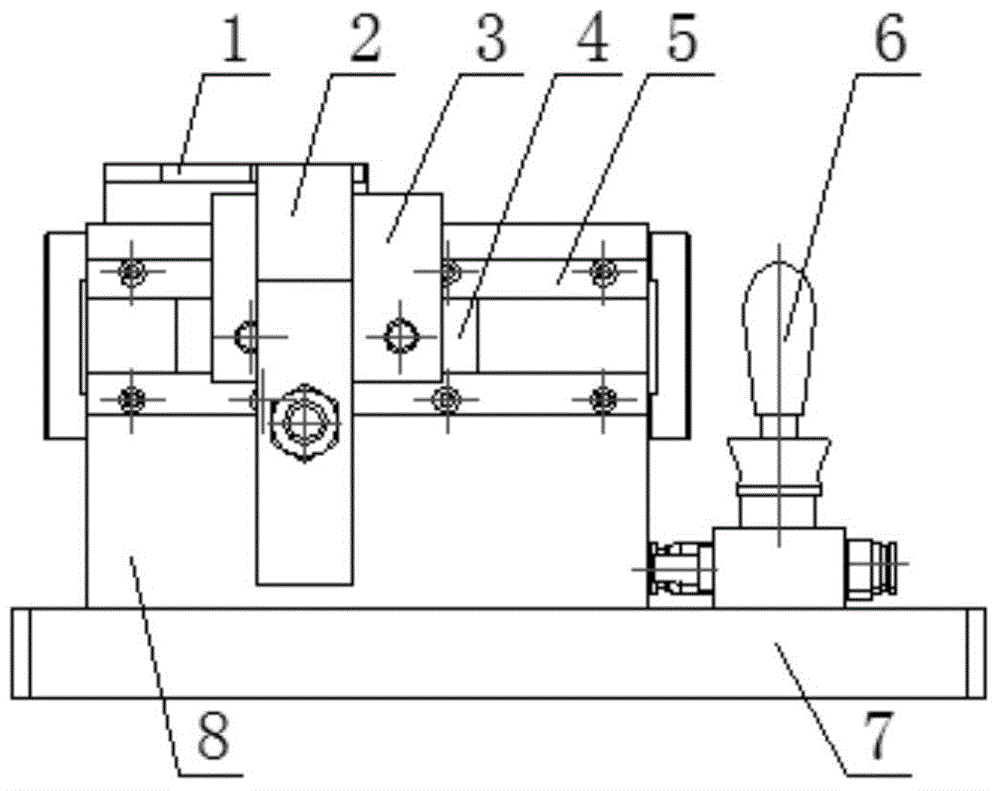

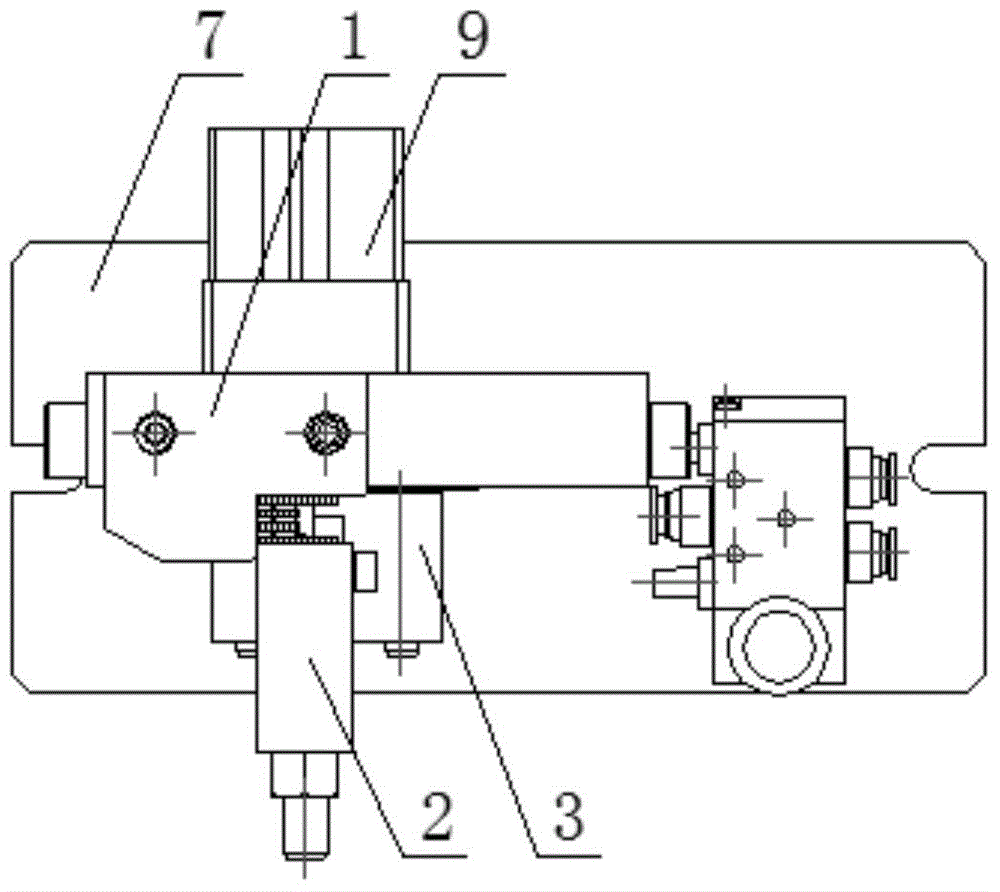

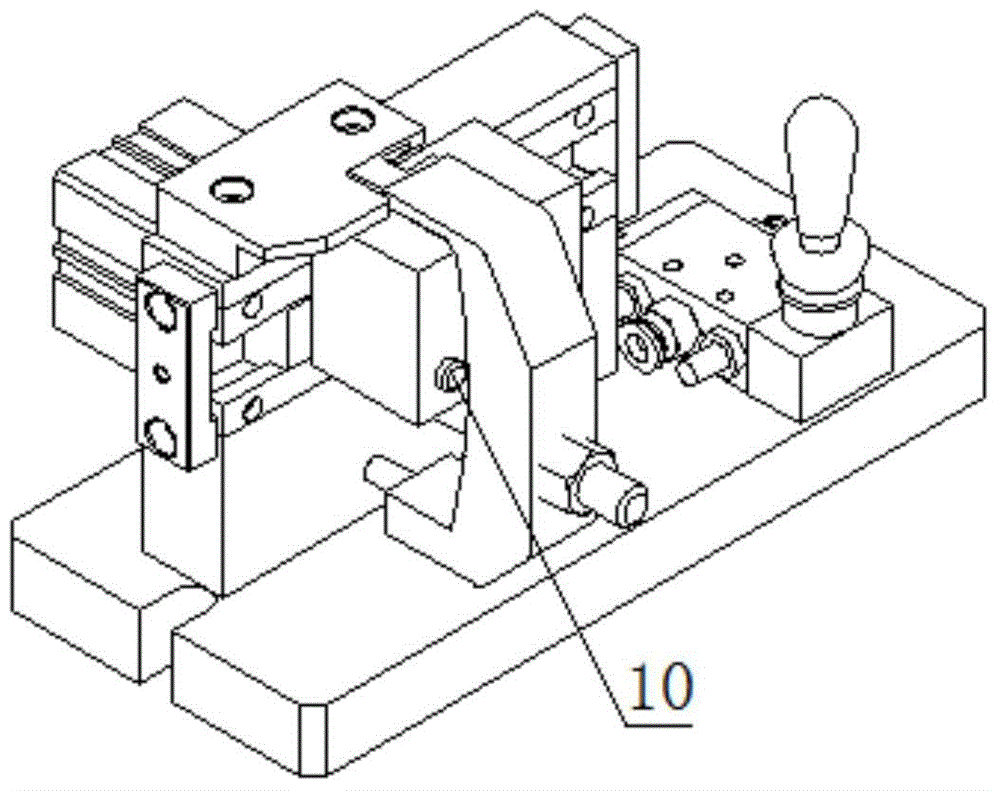

[0016] Disclosed is a special clamping device for sliding positioning of feed dogs and pneumatic clamping for processing, including a bottom plate 7, a vertical plate 8, a clamping cylinder 9, a fastening pressure plate 2, an installation block 3 and a positioning plate 1. The vertical plate is installed on the bottom plate, and a mounting block is slidably installed on the upper part of the front of the vertical plate. 10 is connected with the slider.

[0017] A groove 12 for placing the workpiece 11 is formed on the upper end surface of the mounting block, and a side slot 13 communicating with the groove is formed on the outer side wall of the mounting block. A positioning plate positioned above the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com