Rigidity-adjustable bushing

A bushing and stiffness technology, applied in the field of adjustable stiffness bushings, can solve problems such as poor stability, achieve stable performance, improve handling stability, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

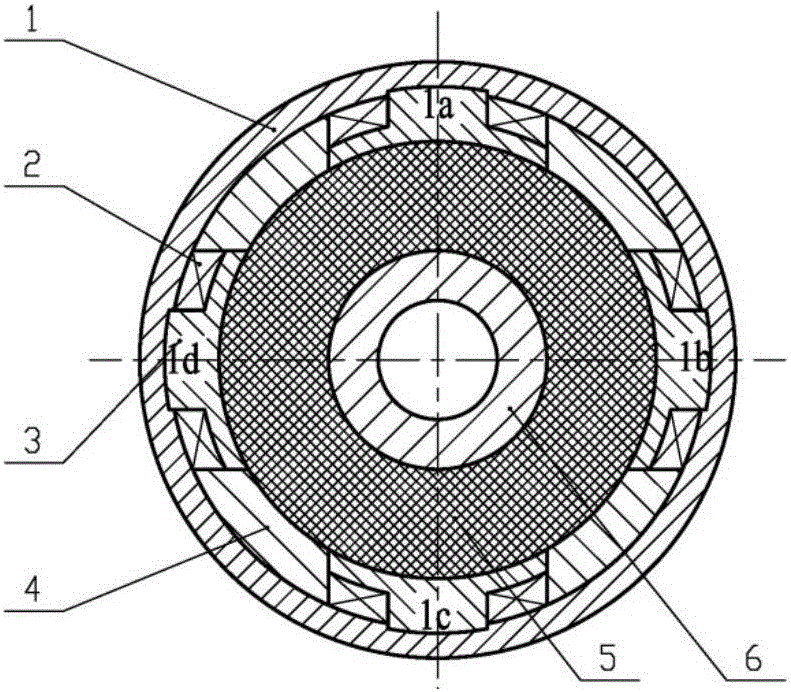

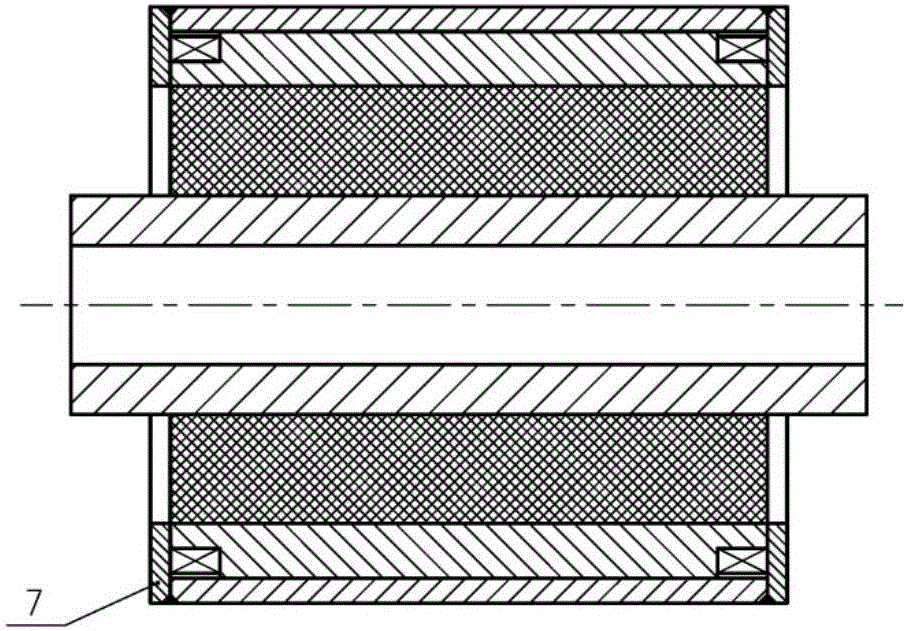

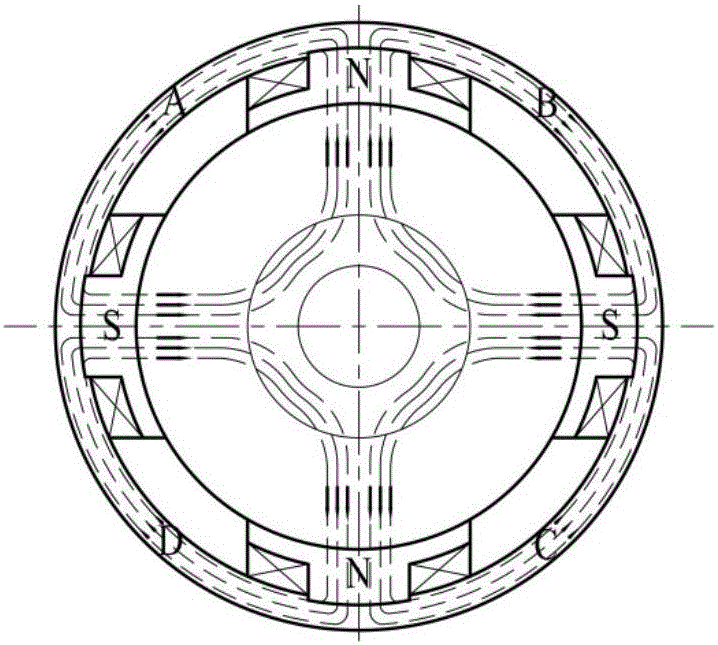

[0033] figure 1 and figure 2 It is the first embodiment of the present invention, including an inner cylinder 6 and an outer sleeve 1 installed coaxially inside and outside, a magnetorheological elastomer 5 is installed coaxially on the outside of the inner cylinder 6, and the magnetorheological elastomer 5 and the outer sleeve 1 Several iron cores 3 are provided, and each iron core 3 is wound with an excitation coil 2 for providing a magnetic field;

[0034] The iron core 3 is tightly matched with the outer sleeve 1, and is positioned through the positioning groove on the inner wall of the outer sleeve 1; a bracket 4 is embedded between the iron core 3 and the outer sleeve 1 to support and fix the iron core 3 ; The two sides of the iron core 3 and the outer sleeve 1 are provided with baffles 7 to prevent the iron core 3 from moving in the axial direction;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com